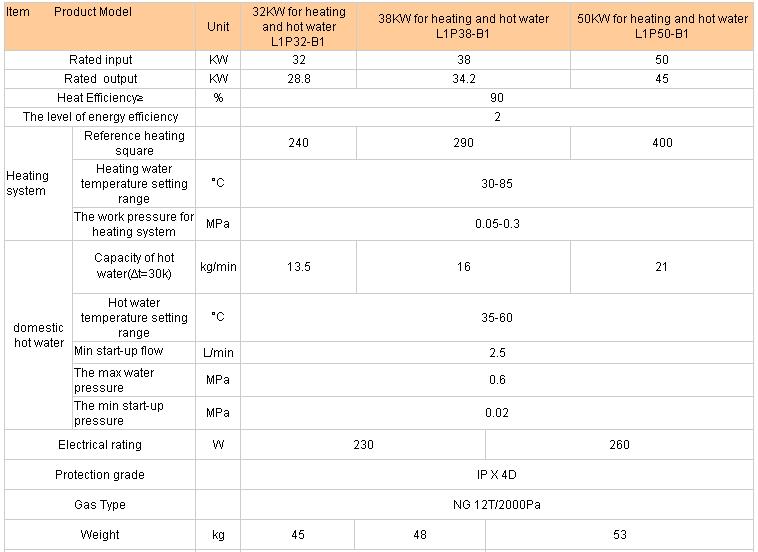

Gas Boiler For Home Floor Heating System L1P50-B1

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Descrition of Product:

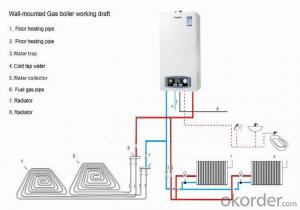

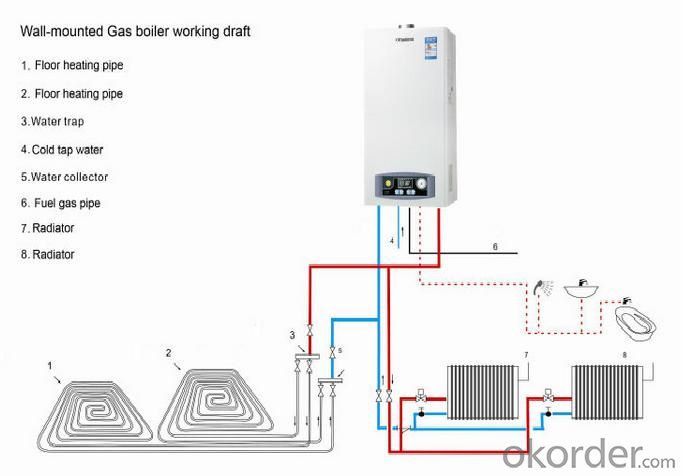

Gas Boiler For Home Floor Heating System L1P50-B1

Model Number: L1P50-B1

Features

1. QS, ISO9001:2008 approve

2. Microcomputer control

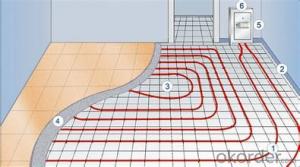

3. Heating&Hot water

4. Hot water Prior

5. Anti-freeze protection

Photo:

FAQ:

① why from okorder?

Okorder is a qualified supplier of all kinds of building matierials in China. All products have been showed in Okorder website are under well controlled by okorder QC team.

All products had been produced under a clear quality standard and the quality is consistence among the shipments.

Okorder has already setted up more than 20 warehouses in different markets to show the products. You are convenient to know the products from your local place and it will help you to make decision easyly.

②How to guarantee the quality of the products?

We have established a perfect quality management system,as for raw material and semi parts all are under strict quality test and we have a IQC system to control the purchases.

QC on site is very strict and all steps of process are measured per drawings. Before delivery, we set a OQC system to make sure each piece meet the standard of order.from design to delivery,

③How long can we receive the product after purchase?

Lead time depending on order quanity, The normal order can be deliveried with 3 weeks.

- Q: 200 flat house with a few vertical air conditioning can be warm

- 200 square meters with air conditioning why not consider the use of warm land. Or air can be combo

- Q: Gas boiler display hh what is the fault

- Dddddddddddddddddddddd

- Q: Taurus to warm what is the characteristics of oxygen

- Oxygen tube only in a closed circulatory system in the role of the central heating is no use. Business a selling point only, no real effect

- Q: Seeking the whole process of the head test pressure, text description, detailed point,

- 1. Test pressure single test pressure and system test pressure, single test pressure: pipe laying or hidden parts of the pipeline after the completion of installation and design requirements according to the requirements of water pressure test. System test pressure: heating system installed according to the design and specification requirements for system water pressure test. 2. Heating, air conditioning system test procedures: a first check the entire system of all control valves are open, the system should be separated from the outer pipe network, open the gas tank release valve. B will be the water supply pipe, test pressure pump and other temporary pressure test pipe connected to the main water supply pipe, and irrigation to the system until the system filled with water and the pipeline system after the air drained (put the wind gate workers The valve out of the water so far), close the release valve; c operation test pump to boost, boost the process should pay attention to check the management, fittings and accessories are leaked, such as leakage should stop the pressure, and after the buck Repair, change pad, tighten and so on. D system without leakage, the pressure and boost to the test pressure, stop the pump check, and observe the pressure gauge, requiring 10 minutes pressure drop of not more than 0.02Mpa, that is qualified.

- Q: Selection of electric heating stove

- Selection of electric heating stove...

- Q: What are the advantages of choosing forward winners?

- Wallpapers are divided into domestic brands, joint venture brands, original imports, genuine original imports due to tariffs and other reasons the price is very high, the use of accessories in the process is also expensive. Wallpapers originated in Europe, because now the procurement of globalization, even the international brands of their parts are also part of the procurement in China, such as the domestic striker group production of heat exchangers (commonly known as water tanks), burning long bones to pay the flap Hold the tower, the main control not only for many domestic brands of fireplaces to buy, but also for most of the brand in Europe. In the domestic production of joint venture brands such as striker boiler, small squirrels and so are the domestic first-line brand, striker boiler like Suning, Gome and other supermarkets also have other brands do not seem to see. Wallpain top ten brands themselves do not have an official ranking, so the meaning is not big.

- Q: What is the basic task of heating engineering? The heating system is composed of some parts

- What is the basic task of heating engineering? The heating system is composed of some parts...

- Q: On the bathroom water seepage problem, the water seepage parts of the wall, the bathroom inside the angle valve, the water into the sea Feng suppression of the economic power of the tibu ax hugs are not, in the end where the water, for explanation, is the following tiles below the reverse water? More

- Where are you specific?

- Q: Just bought a set of three chamber mocking jar ji tian panic bones bite two halls of the house, consider the home with the elderly and children intend to install to warm, do not know what kind of heating equipment to buy? I heard that Granville and Bosch are big European, to understand the people pointing ~ more

- Wei Neng I used the sale after the poor mocking of the tank Jinti panicy Gui sounded into the two did not take long after the boiler is very busy after the sale of a few months did not get better then do not come back very sorry Bosch did not use

- Q: What are the advantages and disadvantages of warming? What kind of heating should be better choice? More

- Look at the area of your house, if you are a villa, then you can consider installing plumbing because you have a place to put the boiler. Plumbing due to the current use of a long time, so all aspects of the technology is relatively mature. If the house area is small, three rooms, 2 rooms, a room of the apartment, then you can consider the installation of heating, easy installation, power consumption is not large. Good heating has an automatic temperature control system, relatively speaking than to save water to save.

Send your message to us

Gas Boiler For Home Floor Heating System L1P50-B1

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 5000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords