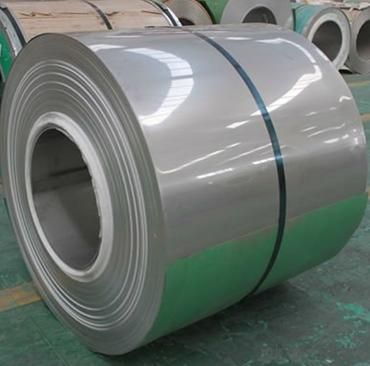

Galvanized Steel for Prefabricated House

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details

Basic Info.

Model NO.:CGCC, SGCC, DX51D, DX51D+Z, TDC51D, TDC51D+Z, G550

Standard:ASTM, JIS, GB, AISI, DIN, BS

Steel Grade:Q195

Surface Treatment:Coated

Technique:Cold Rolled

Thickness:0.12-1.5mm

Width:600-1500mm

Color:as The Ral Color or Sample

Painting Thickness:Top 15-25um+Back 8-10um

Az Coating:30-275G/M2

Raw Material:Galvalume Steel Coil or Galvanized

Delivery Period:Within 15 Days

Production Ability:30, 000mt/Month

Coil Weight:3-5tons

Port:Qingdao

Export Markets:Global

Additional Info.

Packing:Standard Seaworthy Packing

Standard:JIS G3302-1998/EN10142/ASTM

Origin:Boxing, Shangdong, China

HS Code:72107010

Production Capacity:300.000ton Per Year

Product Description

Product Description

NAME: China cheap galvanized steel for Prefabricated house

Thickness: 0.12-1.5mm

Width: 600mm,750mm,762mm,900mm,914mm,940mm,1000mm,1050mm, 1090mm,1100mm,1200mm, 1219mm, 1250mm,1500mm

Length: According to the customer's request

Hardness:Soft( around HRB 65) ,full hard (HRB90-95)

Strength of Extension: more than 300Mpa

Yield Strength:370-380Mpa

Thickness tolerance: +/-0.02 mm

Width tolerance:+/ -2.0mm

ZINC, PAINT & COLOR:

Zinc coating: AZ 30-275G/M2

Paint thickness: Top 15-25um + Back 8-10um

Paint: Epoxy Polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester

Color: As the RAL color standard or customer's sample

PACKING:

Coil weight: 3-5tons

ID: 508mm\610mm

Standard sea worthy package

STANDARD:

JIS G3302-1998/EN10142/ASTM A653/ASTM A792/ AISI/BS/ DIN/GB

Base mental: Hot galvanized steel,SGCC,SPCC,SPHC, DX51D+Z, Q195,etc

Quality: CQ,DQ,DX51D

Lifespan: 10-15 years

APPLICATION:

it is ideal for a wide range of applications,, such as pre-engineered buildings, architectural panels, roofing, siding, cladding, and many other building components.and also used back plate of appliance; wide range of construction, furniture industry, transportation industry, etc.

Base mental | galvanized or galvalume steel coils |

| Thickness | 0.12-1.5mm |

| Width | 600-1500mm |

| Coil Weight | 3-5ton |

| Quality: | DX51D CQ DQ |

| Color | all RAL colors or as per customers' sample |

| AZinc-coating | 30g/m2-275g/m2 |

| Coil ID | 508mm-610mm |

| Packing | standard seaworthy package |

| Technique | cold rolled, hot-dipped galvanizing, color coated |

| Painting | Top and bottom: 20mic+5mic RMP Back: 8mic-10mic |

| Tolerance | Thickness: +/-0.02mm Width: +/-2mm |

| Description | Pre-painted Steel Coil uses hot galvanized steel as its basic material, factory adopts advanced equipment to degrease, rinse, transform the galvanized steel, then make primary and refined lavation to the steel coils. |

| application | They are mainly applied for steel structure buildings, household appliance, furniture, transportation and other industries |

| feature | Pre-painted Steel Coils have excellent performance of decoration, corrosion resistance etc. |

| The special order can be negotiated | |

FAQ:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4.What is the validity of your quotation?

Normally 7 days.

5.What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

- Q: What are the different types of steel coil cutting processes?

- There are several different types of steel coil cutting processes, including shearing, slitting, and laser cutting.

- Q: I'm writing a story, and trying to find out how hot it needs to be for steel to turn into a gas.

- Steel is to broad. There are many types of steel with different melting/boiling points. Iron* has a boiling point of 5182 °F and a Heat of vaporization of 340 kJ·mol?1. iron is the main ingredient of steel, along with carbon and other various elements.

- Q: How is the thickness of a steel coil measured?

- The thickness of a steel coil is typically measured using a tool called a thickness gauge, which is capable of accurately determining the thickness of the steel through direct contact.

- Q: i mean cor ten steel( rusted)

- If the steel is true Cor Ten steel, it does not require waxing. Cor Ten is a steel designed to rust slowly over time ... then the rust acts as a natural barrier to prevent further rust. Check out the United States Steel building in downtown Pittsburgh, PA ... its nickname is The Rusty Nail.

- Q: What are the different types of steel coil coatings for heat resistance?

- There are several types of steel coil coatings available for heat resistance. These coatings are designed to protect the steel surface from high temperatures and prevent oxidation or degradation. One common type of coating is the organic coating, which is typically made of epoxy, polyester, or polyurethane. These coatings provide a protective barrier against heat and prevent the steel from corroding or oxidizing. Organic coatings are often used in applications where moderate heat resistance is required. Another type of coating is the inorganic coating, which is typically made of ceramic or metallic materials. These coatings provide excellent heat resistance and can withstand extremely high temperatures. Inorganic coatings are commonly used in industries such as automotive, aerospace, and power generation, where components are exposed to intense heat. There are also specialized coatings available for specific heat resistance requirements. For example, silicone coatings provide exceptional heat resistance and can withstand temperatures up to 600°C (1112°F). These coatings are commonly used in applications such as exhaust systems, ovens, and industrial furnaces. Additionally, some steel coil coatings may contain additives or fillers to enhance their heat resistance properties. These additives can improve the coating's ability to withstand high temperatures and provide better protection against heat-related issues. In summary, there are various types of steel coil coatings available for heat resistance, including organic coatings, inorganic coatings, and specialized coatings. The choice of coating depends on the specific heat resistance requirements of the application, and factors such as temperature range, duration of exposure, and environmental conditions should be considered when selecting the appropriate coating.

- Q: What are the factors influencing the price of steel coils?

- There are several factors that influence the price of steel coils. 1. Raw material costs: The price of steel coils is directly impacted by the cost of raw materials, such as iron ore and coal. Fluctuations in these commodity prices can greatly affect the overall price of steel coils. 2. Demand and supply: The supply and demand dynamics in the steel industry play a significant role in determining the price of steel coils. If there is a high demand for steel products, the price of steel coils is likely to increase. Conversely, if there is an oversupply of steel, prices may decrease. 3. Production and manufacturing costs: The cost of producing and manufacturing steel coils, including labor, energy, and transportation costs, can impact the final price of the product. Any changes in these costs can influence the overall price of steel coils. 4. Currency exchange rates: Steel is a global commodity, and its price can be influenced by fluctuations in currency exchange rates. If the currency in which steel is traded weakens against other currencies, it can result in higher prices for steel coils. 5. Government regulations and policies: Government regulations and policies, such as import tariffs, export restrictions, and environmental regulations, can impact the price of steel coils. These regulations can affect the cost of production and trade, ultimately influencing the price of steel coils. 6. Market competition: The level of competition among steel manufacturers and suppliers can also impact the price of steel coils. If there are multiple suppliers and manufacturers in the market, it can lead to competitive pricing, potentially driving down the price. On the other hand, if the market is dominated by a few suppliers, prices may be higher. It is important to note that these factors can vary over time and in different regions, ultimately affecting the pricing of steel coils in the market.

- Q: I have been thinking of buying a knife that says it has damascus steel. The reason for the question is that many people told me that damascus steel does not exist anymore, and that damascus nowadays is fake. Is this true???

- damascus steel it says is made from ore containing either tungsten or vanadium, although most tools I've seen are made from chrome vanadium, it wouldn't be hard in this day and age to get the proper material. Although it DOES say in wikipedia that apparently the technique died out a long time ago due to shortage of the ore. Then it talks about reproduction attempts. So theoretically, yes, it could be the deal deal. But it does refer at the bottom about damascend steel which is made with a different technique, you could be buying one of those. NEXT TIME JUST LOOK UP THE ARTICLE YOURSELF AND READ IT

- Q: What are the different types of steel coil storage locations?

- There are several types of steel coil storage locations, including outdoor yards, warehouses, racks, and shelves.

- Q: Is this a strong, durable piece of steel that can take abuse? I'm thinking about using it on a small project.

- Your terms of strong and durable are not specific enough to know what you really need. Are you describing an application where you are using this as a spring or a structural support? Here is description home depot provides: Simpson Strong-Tie straps and plates join and reinforce joints with simple, versatile solutions for a wide range of connections. Available in many lengths, widths and thicknesses, YOur temcan be used on the wide or narrow face of lumber for light repairs or heavy-duty projects. Many straps are designed to be used back-to-back on a piece of lumber without fastener interference. A versatile, medium-duty strap for a variety of connections and splices Designed for use on the edge of 2x members, with a nailing pattern that reduces potential for splitting Install where plates or soles are cut, at wall intersections and as ridge ties 12 in. Length Made from 18-Gauge steel Stainless Steel offers extra corrosion resistance for exterior and treated-wood applications Install with 10d common nails If your application sounds like what they describe you should be fine. If it doesn't you may have trouble. As far as tempering your stainless I doubt you will be successful. If you take a magnet and it is not attracted to this strap, the strap is 304 SS. 304SS only gains strength through work hardening (making it thinner by rolling) Heat treating doesn't affect it.

- Q: How are steel coils inspected for uniformity?

- Steel coils are inspected for uniformity through visual examination and various non-destructive testing techniques. These include measuring the dimensions and weight of the coils, checking for any surface defects or damages, and conducting magnetic particle or ultrasonic testing to detect any internal flaws or irregularities. Additionally, the coils may undergo chemical composition analysis to ensure uniformity in the steel's properties.

Send your message to us

Galvanized Steel for Prefabricated House

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords