Galvanized Steel for Building and Constructions

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details

Basic Info.

Model NO.: dx51d DX52D DX53D

Standard:ASTM, JIS

Steel Grade:Q195

Certification: ISO, SGS

Surface Treatment:Galvanized

Technique:Cold Rolled

Application:Building and Construction

Edge:Mill

Stock:Not Stock

Thickness:0.16-3.0mm

Width:Upon Customr′s Requirement

Length:Upon Customr′s Requirement

Surface:Regular Spangle

Inside Diameter:508 610mm

Outside Diameter:Upon Customer′s Requirement

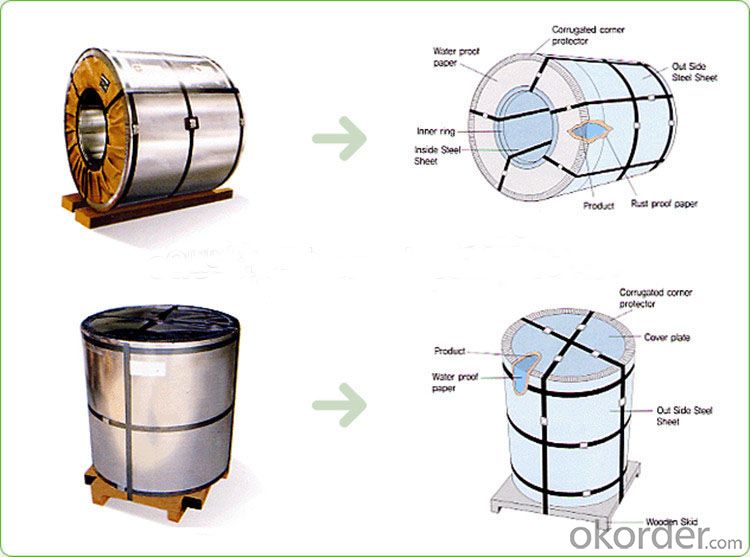

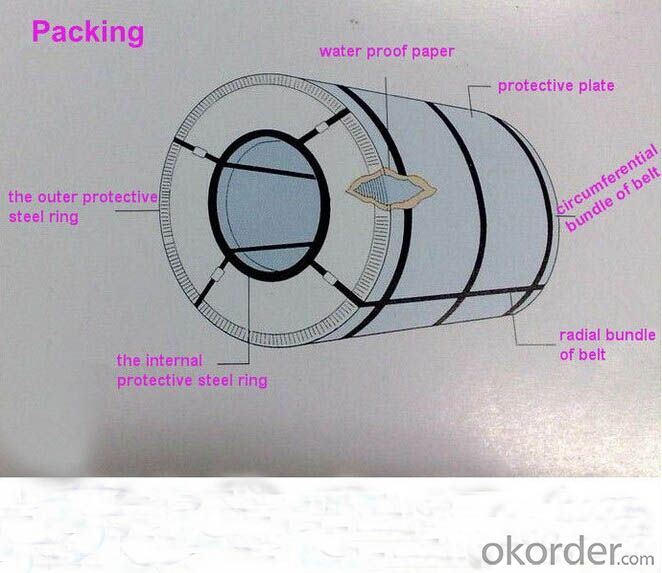

Packing Condition:with Wood Pattet

Sample:Available

Export Markets:Global

Additional Info.

Packing:Sea Worthy Packing

Standard:JIS 3302, EN 10142

Origin:China

HS Code:72104900

Production Capacity:300, 000tons/year

Product Description

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy ,strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications,

Hot-dip aluzinc steel sheet is substrated on cold rolled steel (CRC) in various strength and specification. Coating composition is 55% aluminum in weight ratio, 43.4% zinc, and 1.5% silicon, with excellent corrosion and heat resistance performance.

The Feature of Galvanized Steel:

Commodity: Galvanized Steel in coil or sheet

Standard: JIS G3302 SGCC, commercial quality of the Steel base.

Thickness range of the Galvanized Steel coil: 0.14mm to 3.0mm

Zinc coating from 50-275g/m2

Tolerance of thickness of the Galvanized Steel Roll: +/-0.03mm

Width range: 700mm to 1250mm

Tolerance of width: +/-3.00mm (aiming to +/-2.00mm)

Coil weight of Galvanized Steel coil: According to Clients' requests.

Coil ID: 508 mm

Packing of Galvanized Steel coil: Seaworthy, in container

Note of the GI: Special width can be requested, the small order can be negotiated.

Package:

FAQ:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4.What is the validity of your quotation?

Normally 7 days.

5.What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

- Q: Can steel coils be used in the manufacturing of appliances?

- Appliances can indeed utilize steel coils for their production. They are frequently employed as the principal raw material in the manufacturing of various appliances, including refrigerators, stoves, dishwashers, and washing machines. To meet appliance specifications, these steel coils are typically processed and molded into specific parts like panels, frames, or doors. The utilization of steel coils in appliance manufacturing provides several benefits, such as robustness, longevity, and resistance against corrosion. Moreover, steel coils can be effortlessly fabricated and manipulated to accommodate the distinct design needs of different appliances, making them a versatile and frequently employed material within the industry.

- Q: This is my first time buying new strings for my violin and I’ve narrowed it down to two choice based on reviews and cost. The only difference I can see between the strings is that one has a solid steel core and the other has a synthetic core. What are the pros and cons of each type of core?

- Play okorder /

- Q: I saw an amazing flamenco player, however i have a steel string guitar, where he had a nylon stringed one. So i was wndering if its possible to play flamenco songs on the steel string guitar, and where could i find a tab for it? are there tabs for rasegueados?

- Well, you couldn't play traditional flamenco on a steel string guitar, that's for sure. What you could do is learn some flamenco chords and chord progressions. One problem is that a lot of flamenco techniques on a steel string guitar -- rasgueado, for example -- will literally sand your right hand fingernails down to the nub. It's not going to be pretty, and will probably be painful. Even on a flamenco guitar I protect my right hand nails with a thin coat of super glue. Also, the fingerboard of a flamenco guitar is wider than that of a steel string guitar. That's because many of the notes played in flamenco are actually played with the left hand, not the right hand - lots of hammer ons and pull offs. You can do that higher up the neck on an steel string guitar, but it would be hard to do that in first position on that guitar. Anyway, yes, to a small extent you could conceivably do something that has a flamenco sound on a steel string guitar. But why? You can get a great student model flamenco guitar from Yamaha. It's only $350. Then, you need a teacher. Flamenco is difficult to learn (I've been at it for ten years) and it's important to learn from an instructor who can teach you the correct techniques. Otherwise, you just have to learn everything all over again when you finally do take lessons. Intermediate and advanced students can learn from a video, but beginners really need face time with an instructor. Best wishes.

- Q: What are the common defects in steel coil surface finishes?

- Common defects in steel coil surface finishes can include scratches, pits, rust, oil stains, and uneven coating. Scratches can occur during handling and transportation, and they can affect the overall appearance and performance of the steel coil. Pits are small depressions on the surface caused by a variety of factors such as impurities in the steel or improper processing. Rust can form when the steel coil is exposed to moisture or corrosive environments, and it can weaken the structural integrity of the material. Oil stains can occur if the coil is not properly cleaned before or after processing, leaving unsightly marks on the surface. Uneven coating can happen during the application of protective coatings or paints, resulting in areas with different levels of protection and aesthetics. It is important to address these defects to ensure the quality and durability of the steel coil for its intended applications.

- Q: How do steel coils contribute to the circular economy?

- Steel coils contribute to the circular economy by enabling the recycling and reuse of steel. When products reach the end of their life cycle, steel coils can be easily melted down and repurposed to create new products. This reduces the need for extracting virgin materials, saves energy, and minimizes waste. Additionally, the durability and long lifespan of steel coils ensure that they can be used in multiple cycles, further promoting a sustainable and circular approach to manufacturing and consumption.

- Q: my friend needs sensitive ears....she wants to borrow mine but it says surgical steel,what does that mean?

- Sergical steel means they are earings for sensitive ears. If she borrows them make sure you sanitize them before she wears them.

- Q: How are steel coils used in the production of construction components?

- Steel coils are used in the production of construction components in various ways. One common use is for the manufacture of steel beams and columns, which are essential structural elements in buildings and other large structures. The steel coils are processed and shaped into the desired dimensions, then cut and welded to form the beams and columns. Steel coils are also used in the production of roofing and wall cladding materials for construction. These coils are often coated with protective layers to enhance durability and resistance to corrosion. The coils are then shaped and formed into roofing sheets, wall panels, or siding materials that provide both aesthetic appeal and functional protection to the building. Another important application of steel coils in construction is for the production of reinforcing bars, commonly known as rebar. Rebar is used to provide strength and stability to concrete structures, such as foundations, slabs, and walls. The steel coils are processed and cut into specific lengths, then shaped and twisted to form the required reinforcement bars, which are then embedded within the concrete during construction. Furthermore, steel coils can be used in the production of various other construction components, such as pipes, tubes, and profiles. These components are used for plumbing, heating, ventilation, and other structural applications. The steel coils undergo different manufacturing processes, including rolling, welding, and shaping, to achieve the desired dimensions and properties of these components. In summary, steel coils play a crucial role in the production of construction components. They are used to manufacture steel beams, columns, roofing and wall cladding materials, reinforcing bars, pipes, tubes, and profiles. These components are vital for the construction industry, as they provide strength, durability, and functionality to buildings and other structures.

- Q: How are steel coils priced?

- Steel coils are priced based on various factors such as the current market demand and supply, raw material costs, production and operational expenses, transportation costs, and other market dynamics. Additionally, factors like quality, specifications, and any additional processing or customization required can also influence the pricing of steel coils.

- Q: Why is it usually scorned by the shooting community to use steel cased ammo (like Wolf)? Always hear corrosive and steel is bad for the extractor/firing pin. Hulp a simpleton out!

- I okorder /

- Q: Is there any way to melt steel without the intense heat of a blast furnace?

- Iron melts at a very high temperature, so if the goal is to melt it, then there will be a certain amount of intense heat of course. Steel is recycled in a carbon arc furnace. The bottom is lined in graphite. Large graphite rods are lowered into iron scrap and enormous amounts of electricity melt the iron due to the heating of the carbon due to its resistance. The carbon also removes any oxides by forming CO2. Aluminum and lead can also be recycled in this fashion. Ordinary rust can be turned into liquid iron through the use of the thermite reaction. Rust and aluminum power can be ignited with a propane toarch or a magnesium ribbon fuse. The aluminum is oxidized and the rust reduced to molten iron. This reaction is used to spot weld cracks in steel structures, like railroad tracks. It is also a popular arson device used by spies.

Send your message to us

Galvanized Steel for Building and Constructions

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords