Galvanized Steel Coils Zero Spangle in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

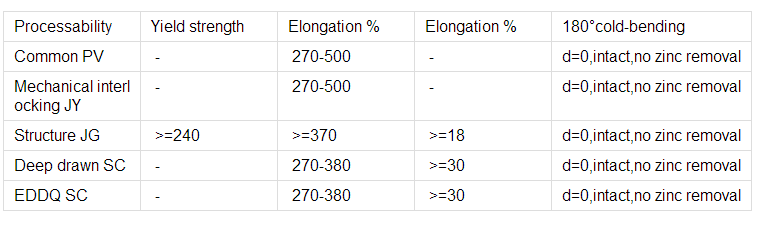

Technology test results:

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: Brass as a rule I believe is betterhowever I do not plan to get into reloading any time soon I just want some cheap practice ammo so will steel case ammo hurt my gun (semi auto) any more than brass ammo and if so how much more?

- I think you answered the question correctly yourself. Yes. BRASS CASE IS BETTER. MUCH MUCH BETTER. Steel case is for the birds. Brass case feeds better in semi-autos as far as I can remember. High end guns all the way to cheapo's, the brass stuff is better. Ever notice how steel case cartridges almost always seem to have visible bulges in the cases right at the butt ends of the bullets? ? ? Not quite so with brass ammo. Cheap shots or expensive shots I prefer ammo in brass.

- Q: How do steel coil manufacturers ensure employee safety?

- Employee safety in steel coil manufacturing is ensured through a range of measures and protocols aimed at preventing accidents, raising awareness, and providing appropriate training and protective equipment. Firstly, regular safety audits are conducted by manufacturers to identify and address potential hazards in the workplace. This involves inspecting machinery, equipment, and facilities to ensure they meet safety standards and are adequately maintained. To cultivate a safety-oriented culture, comprehensive training programs are implemented for all employees. These programs cover various topics such as proper equipment handling, safe practices for material handling, and emergency procedures. In addition, continuous training is provided to ensure employees remain updated on the latest safety protocols and best practices. Personal protective equipment (PPE) plays a crucial role in employee safety within steel coil manufacturing. Manufacturers ensure that employees are equipped with appropriate PPE, such as safety glasses, gloves, helmets, and protective clothing, and are trained in their correct usage. Regular checks are carried out to ensure that PPE is in good condition and promptly replaced when necessary. Manufacturers also employ engineering controls to minimize workplace risks. This may involve installing safety guards on machinery, implementing automated systems to reduce manual handling, and utilizing advanced technology for monitoring and controlling potential hazards. Regular maintenance and inspections are conducted to ensure that these controls function effectively. Moreover, a strong emphasis is placed on communication and employee involvement in safety programs. This includes encouraging employees to report hazards or near-miss incidents, conducting safety meetings and toolbox talks, and actively engaging employees in safety committees or teams. Manufacturers also foster a supportive environment where employees feel comfortable reporting safety concerns and suggesting improvements. Overall, steel coil manufacturers prioritize employee safety through a combination of measures, including regular safety audits, comprehensive training programs, provision of PPE, implementation of engineering controls, and the promotion of communication and employee involvement. These efforts contribute to the creation of a safe and secure working environment for all employees.

- Q: How are steel coils used in the production of agricultural trailers?

- Steel coils are used in the production of agricultural trailers as they are formed into various structural components such as frames, chassis, and supports. These coils are cut, shaped, and welded to create a sturdy and durable trailer structure that can withstand heavy loads and rough terrains commonly encountered in agricultural operations.

- Q: How are steel coils used in the production of steel handles?

- Steel coils are used in the production of steel handles by being processed and shaped into the desired handle design. The coils are uncoiled and fed into a machine where they are cut, bent, and formed to create the handle shape. The coils provide the raw material needed for the manufacturing process, ensuring the handles are strong, durable, and able to withstand the required usage.

- Q: Can steel coils be used in the production of electrical components?

- Yes, steel coils can be used in the production of electrical components. Steel coils are often used as magnetic cores in transformers and inductors. The magnetic properties of steel make it an ideal material for enhancing the efficiency and performance of electrical components. The coils are wound around the steel core, which helps to concentrate and direct the magnetic field, ensuring smooth and efficient operation. Steel coils are also used in the production of solenoids, motors, generators, and other electrical devices where magnetic fields are crucial for their functionality. Overall, steel coils play a vital role in the production of various electrical components, contributing to their reliable and efficient operation.

- Q: I saw a 27 sedan and a 27 Pick-up one had wood wheels the other steel, respectively. Witch one was original or were they both original

- Wooden Spoke Wheels

- Q: What are the common storage defects in steel coils?

- Some common storage defects in steel coils include: 1. Staining or discoloration: If steel coils are not stored properly, they can be exposed to moisture or chemicals, leading to staining or discoloration. This can affect the appearance and quality of the steel. 2. Rust or corrosion: Steel is susceptible to rust and corrosion if it comes into contact with moisture or is stored in a humid environment. Rust can weaken the steel and compromise its integrity. 3. Coil deformation: Improper stacking or handling of steel coils can result in deformation or bending. This can occur when coils are stored on an uneven surface or subjected to excessive pressure or weight. 4. Surface damage: Steel coils can develop surface scratches, dents, or abrasions if they are mishandled during storage. This can be caused by improper stacking, handling, or transport of the coils. 5. Edge damage: If steel coils are not properly protected or secured during storage, the edges can become damaged. This can include chipping, cracking, or bending of the edges. Edge damage can affect the usability and safety of the steel coils. 6. Coil slippage: When steel coils are not securely stored or stacked, they can slip or roll off, causing damage to the coils themselves and potentially causing harm to nearby personnel or equipment. 7. Contamination: Steel coils can become contaminated if they are stored near or come into contact with substances such as dirt, oil, grease, or chemicals. Contaminants can affect the quality and performance of the steel. 8. Coil nesting: Inadequate spacing or stacking of steel coils can result in coil nesting, where one coil becomes embedded or nested within another. This can lead to damage to the coils, making them difficult to separate and use. To prevent these common storage defects, proper handling, storage, and protection measures should be implemented. This includes storing steel coils in a dry, well-ventilated area away from moisture and chemicals, using appropriate stacking and support structures, and providing adequate protection against impacts and contaminants. Regular inspections and maintenance should also be conducted to identify and address any potential defects or issues.

- Q: How are steel coils used in the manufacturing of railway bridges?

- Steel coils are used in the manufacturing of railway bridges as they are rolled and shaped into various structural components like beams, girders, and plates. These coils provide the necessary strength, durability, and flexibility required to support heavy loads and withstand the dynamic forces exerted on the bridge.

- Q: How do steel coils perform in high-temperature applications?

- Steel coils perform well in high-temperature applications due to their excellent heat resistance and structural stability. The high melting point of steel allows it to maintain its strength and shape even at elevated temperatures, making it suitable for various industries such as automotive, construction, and manufacturing. Additionally, steel coils can withstand thermal expansion and contraction without warping or deforming, ensuring reliable performance and durability in extreme heat conditions.

- Q: I'm looking to get a track bike/ fixie to ride around the city of Chicago. I've looked at many bikes and they're mostly made out of Hi Ten steel. My old fixie (which was stolen at North Ave Beach) was made out of aluminum (KHS FLITE 100). How big of a difference is it between aluminum and steel? I know steel is heavier but how does it effect the ride? Is a aluminum bike or a steel bike better to get to ride around the bike path and in the city of Chicago?

- Have you considered going to a motorcycle keep and watching at hybrid or commuter bikes? These will fall into cost range (ie. KHS, Fuji,and so on.). Aluminum is probably lighter than steel however the add-ons could make difference in the weight too. Go together with a motorbike shop that means you will be purchasing from folks who understand what they are selling. A series like performance Bike is a good way to go. The costs are right and which you can get a a lot bigger great bike in your money than you'll in finding at a department retailer, plus they provide lifetime free changes and tuneups.

Send your message to us

Galvanized Steel Coils Zero Spangle in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords