Quick Details

Standard: ASTM

Grade: SHS

Type: Steel Coil

Surface Treatment: Galvanized

Application: Solution hardened steel

Width: 600-1534mm

Length: Coil

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Standard: ASTM

Grade: SHS

Type: Steel Coil

Surface Treatment: Galvanized

Application: Solution hardened steel

Width: 600-1534mm

Length: Coil

| Packaging Details: | Oscillated wound: one coil per bundle, inner is the protecting humidity-proof wax paper. Medium is plastic film. Outer is sackcloth or compound paper packing. Coil to be laid on single type pallet (one pile per pallet) |

|---|---|

| Delivery Detail: | Depends on specification and order quanity. |

Feature:

(1) Type of zinc coating finish: regular spangle, minimized spangle and skin-pass.

(2) Types of surface qualities: as coated surface, improved surface and best quality surface.

(3) Surface treatment: chemically passivated, chromate-free passivation, phosphate, anti-finger print, phosphateand, self lubricating film, and untreated.

(4) Type of oiling: oiled and unoiled.

(5) Coil ID: 508/610mm.

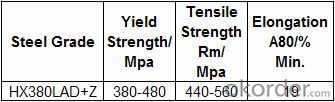

(6) Grade: HX380LAD+Z; Application: high strength steel for cold forming.

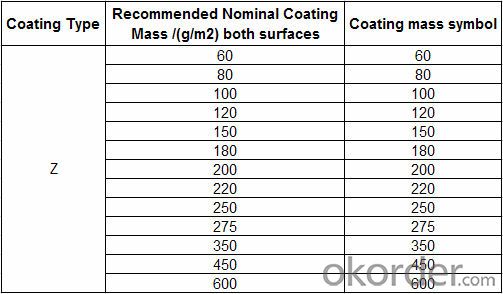

Zinc Coating

Tensile Test Characteristics

What is the application of Steel Coil?

There are two sides,one is out side: Workshop, agricultural warehouse, residential precast unit, corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth;the other is inside: Door, doorcase, light steel roof structure, folding screen, elevator, stairway, vent gutter.

Send your message to us

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords