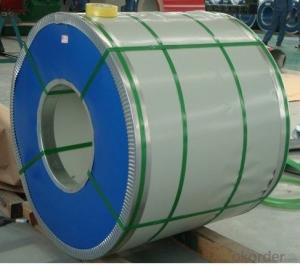

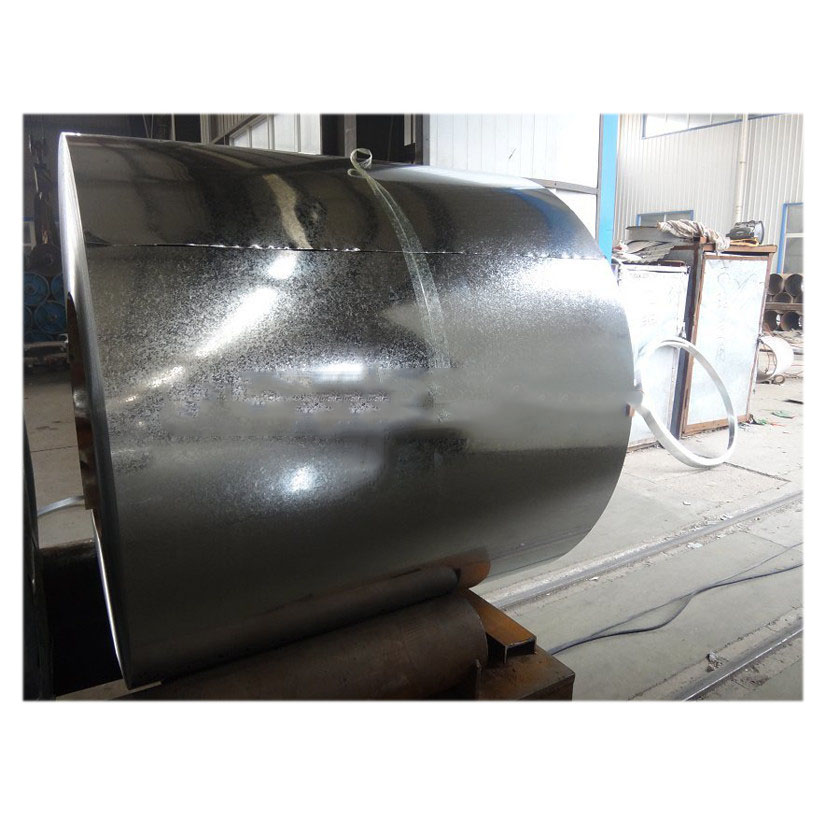

Galvanized Steel Coil High Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 PCS

- Supply Capability:

- 20000 PCS/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

OKorder is offering High Quality Galvanized Steel Coil at great prices with worldwide shipping. Our supplier is a world-class manufacturer of galvanized steel and one of the largest production bases in northern China with a strong technical workforce and advanced equipment. We have supplied more than 400000 metric tons of galvanized steel annually worldwide utilizing two full production lines.

The intended use of High Quality Galvanized Steel Coil

Our High Quality Galvanized Steel Coil is ideal for:

Fabricating applications

Manufacturing applications

The advantages of our High Quality Galvanized Steel Coil

Not only is OKorder's High Quality Galvanized Steel Coil of the highest quality and reliability, we are able to quickly ship orders within 20 days of receiving a deposit or original L/C. We also offer training with experienced engineers to ease installation. Products are designed according to customer requirements and are all durable, boast high stiffness and load-bearing qualities, and are recyclable. All products are shipped with ISO9001 & SGS certification as well as JIS 3302, ASTM A653, EN10143 standards.

Main features of High Quality Galvanized Steel Coil

Additional OEM casting and forging services available

Shipped within 20 Days TT or LC at Sight

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How is our High Quality Galvanized Steel Coil manufactured?

A: Our products are manufactured strictly according to national and international standards, with tests conducted on every product before delivery. Our quality certifications and test reports are available upon request.

Q3: Are products guaranteed?

A: If a product's quality does not match the description provided prior to your order, OKorder offers a full refund.

Q4: Why should you choose us?

A: Sourcing decisions are made based on quality, and then price. We can provide you with both. Additionally, we offer professional product inquiries, product knowledge training (for agents), rapid delivery with factories located near ports and convenient transportation.

Specifications:

Thickness: 0.14mm – 4.5mm TCT

Width: 20mm – 150mm

Individual Weight: 3 – 20MT

Surface Finish: Chromated, skin pass, oiled, slightly oiled, dry, fingerprint-resistant

Surface structure: Zero spangle, minimized spangle, regular spangle, large spangle

Coil ID: 508mm or 610mm

Coating: 40-500g/m² Zinc

Steel Grade: DX51D / DX52D / DX53D / S250, 280, 320GD

Standard: JIS 3302, ASTM A653, EN10143

Temper:

Full Hard: 95 HRB, G500 – G550

Commercial Quality: 70 HRB, G300 – G350

Images:

- Q: When and where did soldiers wearing steel protective helmets start ?It seems to have been common by the start of WW1

- You okorder /

- Q: I recently got in a car accident with a steel mailbox, on a snowy day. I was wondering if i can do anything since the steel mailbox caused my car to be totaled. Otherwise it would have been fine and would have suffered only minor damage. Anything I can do here to maybe get some money back? Thanks!

- The steel mailbox caused my car to be totaled? How did it do that? Did the mail box fail to stop at the stop sign? Did it rear end you when you stopped at the red light? Was the mail box under the influence of drugs or alcohol at the time of the accident? Or, would a more accurate way of putting it is you failed to take weather conditions into account and totaled your car by hitting a mail box? Stop blaming the innocent mail box.

- Q: i cant find this stuff about steel:conductivitystrengthcorrosion resistancecommon applicationsif you know of any interesting facts, i could use those 2!thanx!

- go okorder and search for steel.......

- Q: What are the challenges in coil recoiling?

- Some of the challenges in coil recoiling include achieving precise and consistent coiling, minimizing coil distortion and tangling, preventing material damage or breakage during recoiling, and ensuring efficient and safe handling of coiled materials. Additionally, factors such as coil size, weight, and material properties can also pose challenges in the recoiling process.

- Q: What are the common methods of cutting steel coils?

- The common methods of cutting steel coils include shearing, slitting, and laser cutting. Shearing involves using a machine with two blades to cut through the coil. Slitting involves passing the coil through a set of rotating circular blades to create narrower strips. Laser cutting uses a high-powered laser beam to cut through the steel coil with precision.

- Q: How are steel coils used in the production of heating and cooling systems?

- Steel coils are used in the production of heating and cooling systems as they serve as the primary component for heat transfer. These coils are designed to efficiently transfer heat or cool air, allowing for the effective regulation of temperature in heating and cooling systems.

- Q: Can steel coils be used in the production of construction machinery?

- Yes, steel coils can be used in the production of construction machinery. Steel coils are often used as raw materials for manufacturing various components of construction machinery such as frames, chassis, gears, and structural parts. The high strength and durability of steel make it an ideal material for construction machinery, which often requires heavy-duty performance in tough working conditions. Additionally, steel coils can be easily shaped, welded, and fabricated into the desired forms and sizes, allowing for customization and versatility in the production of construction machinery.

- Q: Can steel coils be recoiled?

- Yes, steel coils can be recoiled. The process of recoiling involves rewinding the steel coil onto a different reel, typically to adjust the coil size or to improve its shape.

- Q: How are steel coils manufactured?

- Steel coils are manufactured through a multi-step process that involves heating and shaping steel slabs, followed by passing them through a series of rolling mills to reduce their thickness and increase their length. The coils are then cooled, inspected for quality, and finally, wrapped and ready for shipping.

- Q: I have some steel wool and a charged 9V Battery, when I connect 2 wires to the battery, then touch the wool with the ends of the wires the wool instantly starts burning, but when I connect 2 wires to the piece of steel wool (a new piece not same one of course) and touch the battery with the ends of the wire nothing happens (see image...)

- Steel Wool 9v Battery

Send your message to us

Galvanized Steel Coil High Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 PCS

- Supply Capability:

- 20000 PCS/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords