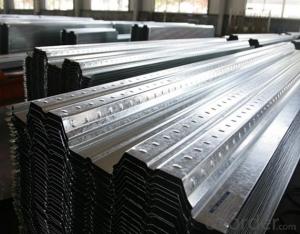

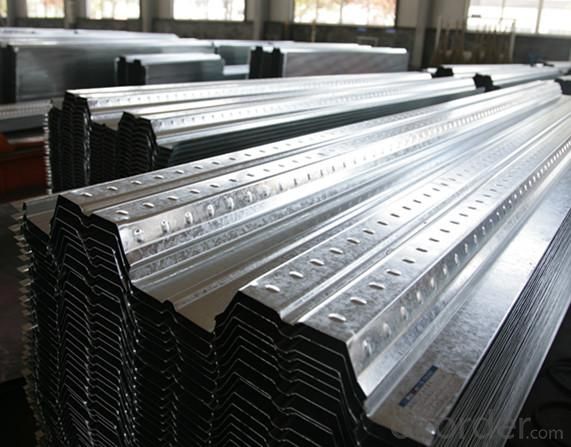

galvanized decking floor sheet good quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Place of Origin: | Beijing China (Mainland) | Brand Name: | DUOWEI | Model Number: | DW720 |

| Material: | Color Steel,galvanized metal steel | galvanized weight: | 80G-275G | coating: | PE ,PVDE,HDP |

| corrosion resistance: | anti-rust |

Packaging & Delivery

| Packaging Detail: | plstaice packing, steel frame packing, pallet and so on |

| Delivery Detail: | 15 days after received the deposit |

Specifications

decking sheet

1.Strong friction and shear performance

2.Perfect fire-resistant performance

3.Excellent floor decking sheet

- Q: Guodong E1 grade 180 plate how to identify

- Guodong is actually only a very popular in the southwest region of the logo, only a logo only, no one can identify whether it is authentic, do not mind too. Any special emphasis on your own use of the country ah LSH Ye like the plate, you should be careful. Our industry, as long as it is out from the manufacturers, are clear Guodong is not any security LOGO (and can not be tested to prove that Guodong produced), and the Guodong like the plate manufacturers are not directly The use of furniture, must be treated through the finishes will enter the furniture factory, and this finishes the process, the importance of the original sheet than ever. Or the words: the economic market, is always a penny of goods (aside from those who do not speak integrity of the business, because their behavior can not be used to measure the normal business theory) Guodong is actually only a very popular in the southwest region of the logo, only a logo only, no one can identify whether it is authentic, do not mind too. Any special emphasis on your own use of the country ah LSH Ye like the plate, you should be careful. Our industry, as long as it is out from the manufacturers, are clear Guodong is not any security LOGO (and can not be tested to prove that Guodong produced), and the Guodong like the plate manufacturers are not directly The use of furniture, must be treated through the finishes will enter the furniture factory, and this finishes the process, the importance of the original sheet than ever. Or the words: the economic market, is always a penny of goods (aside from those who do not speak integrity of the business, because their behavior can not be used to measure the normal business theory)

- Q: KT board is what plate ah? Generally used in where the best picture to explain do not copy copy! To be original

- KT board is a kind of new material which is made of PS particles after foaming to form the board core and pressed through the surface coating. The board is crisp, light, easy to be deteriorated, easy to process and can be printed directly on the board (Silk screen), paint (need to detect paint adaptability), mounted on the gum screen and inkjet, widely used in advertising display promotions, architectural decoration, arts and culture and packaging, etc.

- Q: What does the plate open?

- Sheet material is based on their own use of the drawings size, the large plate into a process to meet their own size.

- Q: Loft shop what board is good

- With the best blockboard, and do not think it is shop under the floor can buy the most. Bad quality is easy to deformation, resulting in the above composite flooring problems. Because, your home is geothermal, blockboard is one side from the bottom of the heat, it is easy to deformation. Multi-layer board can not withstand the test of this heat. Composite floor with geothermal dedicated, must use the brand floor, such as icons, del, and so on. If you want to use plastic steel plate to buy 25 yuan / m or more, aluminum plate to choose 0.8mm thick, the future will not engage in health when the deformation

- Q: PVC sheet size how much the largest

- The main plate is the width, mainly 1.2 meters and 1.5 meters before the main, and now the widest can reach 2.8 or even 3 meters. As for the length is to see what you need, it is continuous production, according to your request cut.

- Q: What is love board?

- AIG is the Austrian Group of Agrites FRITZ EGGER GMBH Co. is located in 17 factories in Europe, the production of man-made sheet, environmental protection level to the European E1 level. The Aige plate substrate is covered with a layer of special dipping treatment, with anti-characterization, acid and alkali surface, is widely used in plate furniture and kitchen furniture, English referred to as MFC. ??????? The love plate is selected from coniferous trees grown in the continental margin of the European continent. The love grid overcomes the shortcomings of natural wood and has physical properties that are not easily deformed and stable. Ai grid is a kind of natural logs by cutting, crushing, high temperature and pressure made of a more suitable for furniture production and use of the plate.

- Q: How to pick up the plate

- Particleboard is also called particle board, bagasse, wood or other lignocellulosic material made of scrap, after the application of adhesive in the heat and pressure under the action of synthetic wood-based panel. Also known as particle board. Is generally bad access

- Q: You can elaborate on this year, a variety of stainless steel products such as: tube, plate, the other, the tax rebate rate is how much

- Stainless steel sheet export tax rebate rate is generally 9 or 13 points, specifically the goods and their exports HS code.

- Q: Moganshan plate how to distinguish between true and false?

- Moganshan plate there are two kinds of anti-counterfeit trademarks, one is "scratch coating" type of trademark, scratch coating, the other is "bar code" anti-counterfeit trademarks. Check the same way.

- Q: Is the cement pressure plate and the cement fiber board a plate? Is there a difference?

- Cement fiberboard and cement pressure plate is a product of two names, in fact no difference. The cementitious materials are cement, and the reinforcing materials are fibers (asbestos fibers and / or cellulose fibers). The name of the fiberboard emphasizes the reinforcement of the material 'fiber'; 'pressure plate' name emphasizes the production process, the use of presses on the board green pressure, squeeze out the water and compaction, improve the board's density and strength. 'Cement fiberboard' is a more traditional name, but in recent years is also known as 'cement pressure plate'. Advantages and Disadvantages of Cement Fiberboard Advantages: cement fiber pressure plate as a new environmentally friendly building materials, in addition to the function of the traditional gypsum board, but also has excellent fire performance and moisture resistance, the advantages of long life, a large number of industrial and commercial applications in the ceiling ceiling and partition, home decoration , Furniture liner, billboard liner, ship compartment board, warehouse floor, network floor and tunnel and other indoor works of the wall. Calcium silicate board processed into the ceiling, with resistance to subsidence, moisture, no dust, non-flammable and other characteristics, an effective solution to mineral wool board gypsum board easy subsidence, short life defects. Calcium silicate board, fiber cement pressure plate is the ideal decoration of the permanent building plate. Walls, ceiling also applies to the wall, the activities of the floor, table, billboards, goods cabinets, kitchen latrines, goods cabinets, fire Pipe, furniture liner, fire door lining. Disadvantages: easy to cause crevice cracking, and deal with the gap is too much trouble. (Thermal expansion and contraction is relatively strong in the reason)

Send your message to us

galvanized decking floor sheet good quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords