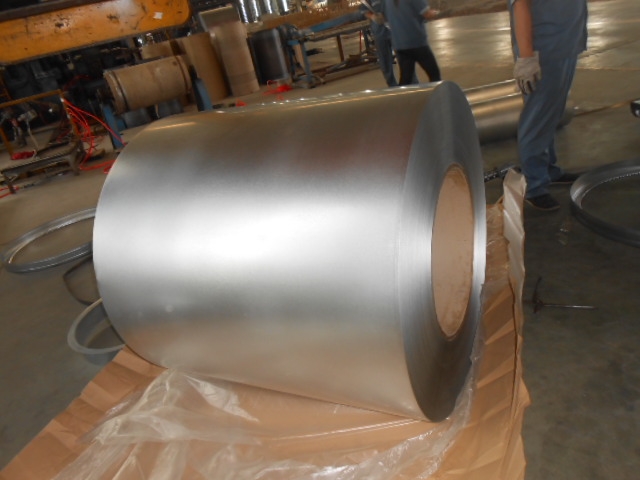

GALVANISED STEEL IN COIL

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

product information:

The Galvalume is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. It enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Specification

1. Thickness: 0.3-0.7mm

2. Width: 914-1250mm

3. Inner Diameter: 508-610mm

4. Weight of Steel Coil: 3-15MT

5. Coating Type: Al-Zn Alloy

6. Available Dipped Layer: 50-150g/m2

7. Surface Finish Structure: Normal Spangle & Small Spangle & Zero Spangle

8. Available Surface Treatment: Passivating & Oiling & AFP & Filming

Mechanical Properties

Grade | Tension Test | ||

Yield Strength (MPa) | Tensile Strength (MPa) | Elongation% No Less Than | |

A80mm | |||

DX51D+AZ | 140-350 | 270-500 | 22 |

DX52D+AZ | 140-300 | 270-420 | 26 |

DX53D+AZ | 140-260 | 270-380 | 30 |

Application

1. Architecture Roofs and outside walls of civilian and industrial buildings, garage doors, fencings and window blinds

2. Appliances Industry Outer clad sheets for washing machine, refrigerator, television, air conditioner and ventilation system, explosion-proof strip, solar water heater and appliance parts

3. Auto Industry Muffler, heat shields of exhaust pipe and catalytic converter, auto parts & accessories under the frame, signboard in highway

4. Industrial Instruments Electric control cabinet, industrial refrigeration equipment, automatic vending machine

- Q: were iron age weapons made of steel?

- Even in very early iron, a small amount of steel was produced by carburization, where the iron picks up carbon by laying in hot coals before quenching. This produces a thin layer of steel on the surface of the iron. By about 300 BC Damascus steel was being produced by the crucible method on the Indian subcontinent, and the Romans used steel from Noricum. In the first century BC the Chinese were melting cast iron and wrought iron together to make steel.

- Q: Why can hot rolled coils be placed outside?

- Because hot-rolled steel coils are generally used as raw material for semi-finished products, they have to be further used for pickling and cold rolling to make more use. The rust and dust can be removed after pickling

- Q: What are the different methods of testing steel coils for quality control?

- Steel coils undergo various methods for quality control testing to ensure they meet the necessary specifications and standards. These methods encompass visual inspection, dimensional measurement, hardness testing, tensile strength testing, chemical analysis, coating thickness measurement, surface roughness measurement, ultrasonic testing, and magnetic particle inspection. Visual inspection is the most fundamental technique, involving a thorough examination of the coils for surface defects like scratches, dents, or irregularities. This method enables the identification of visible defects in the material. Dimensional measurement, on the other hand, utilizes tools such as calipers, micrometers, or laser measuring devices to evaluate the dimensions of the steel coils. The measurements are compared against specified tolerances to ensure they meet the required standards. To assess the resistance of the steel coils to indentation or penetration, hardness testing is performed. This examination helps evaluate the material's strength and durability. Common hardness testing methods include Rockwell, Brinell, and Vickers hardness tests. Tensile strength testing measures the maximum tensile stress a steel coil can endure before breaking or deforming. This test helps determine the material's strength, elasticity, and compliance with the required specifications. Chemical analysis is crucial in testing the composition of the steel coils to verify the presence of specific elements in the desired amounts. This ensures that the coils are made from the correct grade of steel and comply with the required chemical composition standards. In cases where the steel coils have a protective coating, it is vital to measure the thickness of the coating. Non-destructive testing methods like magnetic induction or eddy current testing are typically employed for this purpose. The coating thickness is compared against the specified requirements to ensure it provides adequate protection. Surface roughness testing evaluates the smoothness or roughness of the steel coil's surface using instruments like profilometers or roughness testers. This testing method guarantees that the coils meet the required surface finish standards. Ultrasonic testing utilizes high-frequency sound waves to detect internal defects like cracks, voids, or inclusions within the steel coils. This non-destructive testing method provides valuable information about the structural integrity of the coil. Magnetic particle inspection is employed to identify surface and near-surface defects in steel coils. By applying magnetic particles to the surface and detecting any magnetic leakage caused by defects using magnetic sensors, this technique effectively detects cracks and other surface abnormalities. By combining these testing methods, manufacturers ensure that the steel coils produced meet the necessary quality standards and are suitable for their intended applications.

- Q: I installed it, added it in F3 launcher and then after one minute of walking in wasteland I get a signal that Broken steel was added and that my level of caps was raised by 30. However after this message no quest is added. I played all 4 exp. packs and I had no problem at all, each time a new quest was added. So whats up with this Broken steel. Btw, I completed the entire game F3.

- Broken Steel's quests activate once you have beaten the final mission in the purifier. If you have already beaten the game, then you should just go back to the purifier and beat it again, since normally you wouldn't be able to continue to play the game once you have beaten it without Broken Steel. If you were able to continue playing the game, then it's likely that whatever mod you used is interacting with the game and making it impossible for Broken Steel to activate.

- Q: Or is it a coating that is applied? If so what types of steel? Or what types of coatings?

- No, usually they are just coated or galvanized. To make a steel that is truly more corrosion resistant raises it's cost quite markedly, where as coatings are pretty cheap. Almost all structural steel is just A36 mild steel (like 0.1% carbon, 0.05% Mn, and not much else). There are higher grades of structural steel, and bridges are made with truly more corrosion resistant carbon steels, but for a house it's just not the case.

- Q: How are steel coils used in the manufacturing of industrial conveyors?

- Steel coils are used in the manufacturing of industrial conveyors as they provide the necessary strength and durability required to support heavy loads and withstand the rigors of continuous operation. The coils are typically formed into various components, such as frames, rollers, and supports, that make up the conveyor system. By utilizing steel coils, manufacturers can ensure a reliable and efficient conveyor system that can handle a wide range of materials and processes in industrial settings.

- Q: How are steel coils used in the manufacturing of automotive accessories?

- Due to their strength, durability, and versatility, steel coils find widespread use in the manufacturing of automotive accessories. These coils act as the primary raw material for various components and parts utilized in the automotive industry. One notable application of steel coils in automotive accessory production involves the creation of body panels and frames. These coils are shaped and formed according to desired specifications, and subsequently undergo cutting, stamping, and welding processes to fabricate the body panels and frames of vehicles. The exceptional strength of steel coils ensures that the resulting body panels and frames possess the necessary robustness to endure daily use and provide structural integrity to the vehicles. Moreover, steel coils are also employed in the production of automotive suspension systems. Specifically, coil springs, which constitute integral elements of the suspension system, are commonly fashioned from steel coils due to their capability to absorb and distribute the weight and impact of the vehicle. By supplying essential support and shock absorption, these coil springs contribute to a smooth and comfortable ride. Furthermore, steel coils are utilized in the manufacturing of various automotive accessories like exhaust systems, brackets, and other components. These coils are shaped and formed into the desired designs, and subsequently undergo cutting, bending, and welding procedures to fabricate these accessories. The strength and durability of steel render these accessories capable of withstanding high temperatures, vibrations, and other harsh operating conditions. In conclusion, the utilization of steel coils plays a pivotal role in the manufacturing of automotive accessories. Their provision of necessary strength, durability, and versatility facilitates the production of various components and parts. From body panels to suspension systems and accessories, steel coils significantly contribute to the overall quality, performance, and safety of automotive accessories.

- Q: like, what can steel make?

- buildings bridges automobiles elevators railroads and railroad equipment appliances and many many more. Steel is used almost everywhere. reference: Iron and steel are used widely in the construction of roads, railways, infrastructure, and buildings. Most large modern structures, such as stadiums and skyscrapers, bridges, and airports, are supported by a steel skeleton. Even those with a concrete structure will employ steel for reinforcing. In addition to widespread use in major appliances and cars (Despite growth in usage of aluminium, it is still the main material for car bodies.), steel is used in a variety of other construction-related applications, such as bolts, nails, and screws.[66] Other common applications include shipbuilding, pipeline transport, mining, offshore construction, pipeline transport, aerospace, white goods (e.g. washing machines), heavy equipment (e.g. bulldozers), office furniture, steel wool, tools, and armour in the form of personal vests or vehicle armour (better known as rolled homogeneous armour in this role). .

- Q: How are steel coils used in the manufacturing of machinery?

- Steel coils are used in the manufacturing of machinery as they provide a reliable and durable material for various components and structures. These coils are often shaped, cut, and formed into desired parts such as gears, shafts, frames, and supports. The high strength and versatility of steel coils allow them to withstand heavy loads and harsh conditions, ensuring the machinery's efficiency and longevity.

- Q: What are the factors affecting the formability of steel coils?

- There are several factors that can affect the formability of steel coils, including the composition and microstructure of the steel, the thickness and width of the coils, the temperature at which the forming process takes place, the lubrication used during forming, and the equipment and techniques employed.

Send your message to us

GALVANISED STEEL IN COIL

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords