Galvanised Steel Coils with ISO 9001:2008

- Loading Port:

- Nanjing

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 40000 PCS/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Galvanised Steel Coils with ISO 9001:2008 Details

| Standard: | AISI,ASTM,BS,DIN,GB,JIS | Grade: | SGCC |

| Place of Origin: | China (Mainland) | Width: | 700-1250mm |

| Thickness: | 0.13-0.8mm | Technique: | Cold Rolled |

| Application: | home appliances, constructions, building, machineries | Special Use: | High-strength Steel Plate |

| Length: | as customer's requirement | Certificate: | ISO9001, BV |

| surfact treatment: | galvanzied | Unit weight: | 3-5t/coil |

| OEM: | Accept | Zinc coated: | 30-180g/m2 |

Packaging & Delivery

| Packaging Detail: | GALVANISED STEEL COILS WITH ISO9001:2008 waterproof paper, galvanized steel covered and steel strip packed. |

| Delivery Detail: | 30 days after deposit |

Galvanised Steel Coils with ISO 9001:2008 Specifications

| Material | SGCC, DX51D+Z |

| Thickness | 0.13-0.8mm |

| Width | 750-1250mm |

| Zinc coated | 40-180g/m2 |

| Standard | ASTM,AISI,DIN,GB |

| Spangle | Zero Spangle, Regular Spangle, Small Spangle |

| Surface treatment | chromated and oiled, chromated and non-oiled |

| Technique | cold rolled galvanized |

| Grade | Prime |

| ID | 508mm or 610mm |

| Coild weight | 3-5MT/Coil or as your request |

| Quality | Softy , half hard and hard quality |

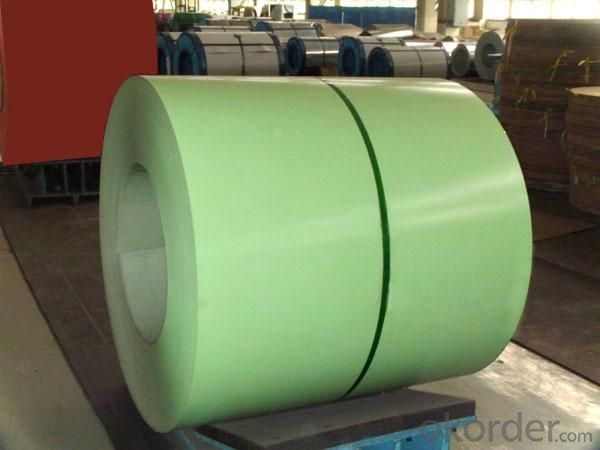

Galvanised Steel Coils with ISO 9001:2008 Pictures

- Q: How are steel coils used in the production of aerospace parts?

- Due to their strength, durability, and versatility, steel coils find extensive use in the aerospace industry for the production of aerospace parts. Made from high-quality carbon steel, these coils are formed into a coil shape, facilitating their transportation and storage. In the aerospace sector, steel coils play a crucial role in manufacturing different components, including structural parts, engine parts, landing gear, and fasteners. Specifically, steel coils are extensively employed in the fabrication of aircraft frames and fuselage structures. These coils are often cut, shaped, and welded to create the necessary structural components, which contribute to the aircraft's strength and stability. Another significant application of steel coils in aerospace production is the manufacturing of engine parts. Complex shapes are formed from the processed steel coils to produce components like turbine blades, shafts, and casings. These components must withstand high temperatures, pressure, and stress, and steel coils possess the requisite strength and heat resistance for such demanding applications. Furthermore, steel coils find utility in the production of landing gear, which supports the aircraft during takeoff, landing, and ground operations. The processed steel coils are shaped into various parts of the landing gear system, including struts, beams, and brackets. These components undergo rigorous testing and require excellent strength, toughness, and fatigue resistance, all of which are provided by steel coils. Additionally, steel coils are commonly employed in the manufacturing of fasteners essential for aerospace applications. Bolts, screws, and rivets play a crucial role in joining different components together, ensuring structural integrity and safety. Steel coils are processed and formed into the desired shapes for these fasteners, offering the necessary strength and reliability for these critical connections. In summary, steel coils are indispensable in the production of aerospace parts due to their exceptional mechanical properties and reliability. Their versatility enables various shaping and processing techniques, allowing for the creation of complex and high-performance components. By incorporating steel coils into aerospace manufacturing, the industry can ensure the production of durable, safe, and efficient aircraft.

- Q: Can a steel at 0.0055 of thickness still be powerful enough to bash skulls? As well as stop handgun cartridges or at least weaken them?You see, i had an idea of making a cylindrical Knuckles made from steel. By my dimensions, 5in diameter, 12 inch h1 and 15 in h2. Half-Sphere: a sphere that is cut in half for the dome at the fist:( [ pi x ( d ^ 3) ] / 6 ) / 2Cylinder

- I don't follow your calculations. It seems to me that the piece you show could be made from .01 steel and still be less than a pound. Also, it is hard to get steel thinner than .015 because anything thinner is not very useful. If you made it out of .015 steel and used a high strength steel, it might be useful. You wouldn't be bashing any skulls, but with some spikes on the end, it could do some damage, and protect against knives or other hand weapons. You also won't get any bullet resistance out of anything that thin. If you want to bash skulls and deflect bullets, you have to get up to at least .10 and several pounds. Any weight on your hands slows down the speed of your punch, but this is compensated for by the increased energy of impact carried by the extra mass. Also, having something hard to protect your hands allows for harder hits and more damage to the opponent. An interesting idea, but it would take some testing to figure out the optimum configuration. One problem I see is that it completely encloses the hand, making it impossible to use the hand for anything else. So you would have to put it on and take it off a lot, and there would be cases where you wouldn't be able to put it on when you needed it. For that reason, I would not wear two at one time. I would make it heavier and wear it on one hand for bashing skulls and deflecting weapons, and keep the other hand free for other things.

- Q: How are steel coils processed and shaped into specific products?

- Steel coils are processed and shaped into specific products through a series of steps, involving various machinery and techniques. The process begins with the steel coils being unwound and flattened using a decoiler and a leveller. This step ensures that the coils are ready for further processing. Next, the flattened coils are fed into a rolling mill, where they undergo a process called cold rolling. Cold rolling involves passing the coils through a series of rollers to reduce their thickness and improve their surface finish. This process also enhances the strength and hardness of the steel. After cold rolling, the steel coils may undergo additional processes such as annealing or galvanizing, depending on the desired properties of the final product. Annealing involves heating the coils to a specific temperature and then slowly cooling them, which helps to relieve internal stresses and improve the steel's ductility. Galvanizing, on the other hand, involves coating the coils with a layer of zinc to protect them from corrosion. Once the necessary treatments are completed, the steel coils are ready to be shaped into specific products. This is achieved through various methods such as cutting, stamping, or forming. Cutting involves using shears or lasers to trim the coils into specific sizes or lengths. Stamping involves using a die and a press to shape the coils into intricate designs or patterns. Forming, on the other hand, involves bending or shaping the coils using specialized machinery to create curved or contoured products. Finally, the shaped steel products are inspected for quality and undergo any necessary finishing processes such as painting or coating. This ensures that the products meet the required specifications and are ready for distribution or further assembly. In summary, steel coils are processed and shaped into specific products through a combination of steps including unwinding, flattening, cold rolling, annealing or galvanizing, cutting, stamping, forming, inspection, and finishing. Each of these steps plays a crucial role in transforming the raw steel coils into high-quality products used in various industries.

- Q: How are steel coils used in the manufacturing of agricultural silos?

- Steel coils are used in the manufacturing of agricultural silos to create the cylindrical structure of the silo. These coils are rolled and shaped into large, seamless rings that form the walls of the silo. The coils provide strength and durability to withstand the weight of the stored grain or other agricultural products, ensuring the structural integrity of the silo.

- Q: What are the common coil surface treatments?

- The common coil surface treatments include galvanization, painting, and powder coating.

- Q: How are steel coils processed for edge trimming or conditioning?

- Steel coils are processed for edge trimming or conditioning through a series of steps. First, the steel coils are unwound and fed into a machine that trims the edges to remove any irregularities or imperfections. This process helps ensure that the edges of the steel coils are straight and smooth. After edge trimming, the coils may undergo further conditioning processes such as leveling, slitting, or recoiling, depending on the specific requirements of the end product. These processes help to refine the steel coils and prepare them for various applications in industries such as automotive, construction, or manufacturing.

- Q: How are steel coils cut into smaller sizes?

- Steel coils can be cut into smaller sizes using various methods, depending on the desired dimensions and quantities. One common method is called slitting, which involves passing the coil through a set of circular blades. These blades make multiple cuts simultaneously, creating narrower strips of steel. Slitting is often used to produce narrow coils or strips for specific applications such as automotive parts or electrical components. Another method is called shearing, which involves using a straight blade to cut the coil into smaller lengths. This method is typically used when precise dimensions are required, such as for manufacturing flat sheets or plates. Shearing can be done manually or using automated machinery. Additionally, some steel coils can be cut using laser or plasma cutting techniques. These methods allow for more flexibility in terms of shape and size, as they can create intricate cuts or contours. Laser or plasma cutting is commonly used when specific shapes or profiles are needed for applications like construction or fabrication. Overall, the process of cutting steel coils into smaller sizes involves various techniques such as slitting, shearing, laser cutting, or plasma cutting. The choice of method depends on factors such as the desired dimensions, quantities, and specific requirements of the end product.

- Q: How are steel coils processed for specific applications?

- Steel coils are processed for specific applications through a series of carefully planned steps. The process begins with the selection of the appropriate grade and thickness of steel, which is determined based on the requirements of the end application. Once the steel coils are received, they undergo a series of processing steps to transform them into the desired product. The first step in processing steel coils is known as uncoiling, where the coil is unwound and straightened. This ensures that the coil is flat and ready for further processing. The uncoiled steel is then cleaned to remove any dirt, oil, or rust that may be present on the surface. This is typically done through a process called pickling, which involves immersing the steel in a bath of acid to remove any impurities. After cleaning, the steel undergoes various shaping processes depending on the desired application. This can include processes such as slitting, where the coil is cut into narrower strips, or shearing, where it is cut into specific lengths. These shaping processes are often performed using specialized machinery that can handle the high strength and thickness of steel. Once the steel has been shaped, it may undergo additional processes to enhance its properties. For example, it may be heat treated to increase its strength or hardness, or it may undergo a coating process to improve its corrosion resistance. Coating processes can include techniques such as galvanizing, where the steel is coated with a layer of zinc, or painting, where it is coated with a layer of paint. Finally, the processed steel coils are inspected for quality and undergo any necessary finishing processes. This can include processes such as trimming the edges to remove any irregularities, or applying protective coatings to prevent damage during transportation or storage. Overall, the processing of steel coils for specific applications is a complex and carefully controlled process. It involves a combination of shaping, cleaning, coating, and finishing processes to ensure that the steel meets the required specifications and is ready for use in various industries such as automotive, construction, and manufacturing.

- Q: How are steel coils used in the production of containers?

- Steel coils are used in the production of containers as they are the primary material for manufacturing container bodies. These coils are shaped and welded into the desired container shape, providing strength and durability to the final product.

- Q: I need to know what steel's weakness is.

- Steel has three weaknesses. They are Fire, Fighting, and Ground. Ice, Flying, Psychic, Bug, Rock, Ghost, Dragon, Steel and Normal aren't effect on Steel pokemon, so I would advise not to use those types. And Poison causes NO damage whatsoever on Steel pokemon. Water and Electric type moves cause normal damage. Happy Pokemoning! :)

Send your message to us

Galvanised Steel Coils with ISO 9001:2008

- Loading Port:

- Nanjing

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 PCS

- Supply Capability:

- 40000 PCS/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords