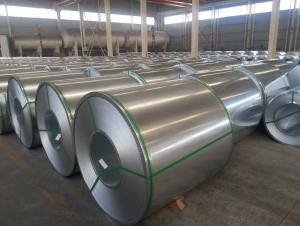

Galvalume STEEL coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Specification:

Thickness: 0.2-3.0mm

Width: 600-1500mm

Coating Mass: Z08,Z12,Z18,Z20,Z22,Z25,Z27,Z35

Z80,Z120,Z180,Z200,Z220,Z250,Z275

Tolerance for thickness,width,flatness and so on conform to the requirements of JIS G3302 or ASTM A653M/924M

Coil ID can be either 508mm or 610mm, maximum coil OD is 2000mm

The speicfication of ASTM Such as A653m,A924 M and so on have been updated to the latest revisions

Application:

BUILDING & CONSTRUCTION

Floor decks, ceilings, verandas, rolling doors, warehouse, partitions, sheds, gutters, wall, underground piping, sashes, beams, fences, scaffolding, indoor decorations, ducts, ventilating pipes, steel frames and cable trays.

ELECTRICAL APPLIANCES

Freezers, video recorder cases, motor cases, lighting fittings, water heaters, washing machines, refrigerators, stoves, air conditioners, dehumidifiers, fluorescent light housings, electrical heaters, toasters, microwave oven enclosures and switch boxes.

TRANSPORTATION

Containers, under body panels, bus & truck body panels, fuel tanks, noise screens, highway signs, air cleaners, conveyor systems and guard rails.

AGRICULTURAL EQUIPMENT

Barns, drying machines, animal houses, hoppers, irrigation systems, greenhouses, water tanks, sheds, silos, agricultural implements and feeders.

FURNITURE & OTHERS

Vending machines, drums, cans, pails, sauna inner parts, chimney pipes, entertainment machines, solar collectors, office equipment, steel furniture, tool boxes, garages and waste bins.

COMPUTER'S APPLIANCES

Computer shells and communication instruments。

Surface Treatment:

Chromating treatment or anti-finger print

Surface Finished:

REGULAR SPANGLE:

Regular spangle is also called normal spangle which is naturally formed without any additional treatment during galvanizing.

MINI SPANGLE:

The spangle is restrained and formed as mini spangle by reducing the lead content in the zinc liquid or by blowing the zinc powder from the equipment installed on the zinc pot.

EXTRA SMOOTH:

The mini spangle is further skin-passed to produce the extra smooth surface.

- Q: How are steel coils coated or painted?

- Steel coils are typically coated or painted using a process known as coil coating. This involves a series of steps including cleaning, pretreating, applying primer, and applying the final topcoat. The coils are first cleaned to remove any dirt or contaminants. They are then pretreated to enhance adhesion and corrosion resistance. After that, a primer is applied to provide a base layer for the paint. Finally, the desired topcoat is applied using various methods such as roll coating, spray coating, or electrostatic coating.

- Q: hi to every one I need to konw moer about steel and iron industry (process) thank you in advance for your intresting

- Steel is made from injecting air into molten iron

- Q: How are steel coils used in the manufacturing of railroads?

- Steel coils are used in the manufacturing of railroads to produce rails, which form the tracks that trains run on. These coils are rolled into long, straight sections and then shaped into the required rail profile. The rails are then cut to the desired length and undergo various processes, such as heat treatment and finishing, to enhance their strength and durability. Overall, steel coils are a crucial raw material in the creation of reliable and robust railroad infrastructure.

- Q: How are steel coils used in the manufacturing of transmission systems?

- Steel coils are used in the manufacturing of transmission systems to create various components such as gears, shafts, and bearings. These coils are often transformed into flat sheets or strips, which are then shaped and processed to form the required parts. The strength and durability of steel make it an ideal material for transmission systems as it can withstand the high stress and torque associated with transmitting power from the engine to the wheels efficiently and reliably.

- Q: What are the dimensions of steel coils used in the electrical equipment industry?

- The dimensions of steel coils utilized in the electrical equipment industry may differ based on the particular application and requirements of the equipment being produced. However, there are certain dimensions that are commonly employed in this industry. Typically, the width of steel coils employed in the manufacturing of electrical equipment ranges from 0.5 inches to 72 inches (1.27 cm to 182.88 cm). The thickness of these coils can vary from extremely thin, measuring 0.005 inches (0.0127 cm), to considerably thick, measuring 0.25 inches (0.635 cm). The length of steel coils employed in the electrical equipment industry can also vary, but it is often determined by the production process and the specific equipment being manufactured. Coils can range in length from a few feet to several hundred feet. Moreover, the weight of steel coils can differ based on their dimensions and the type of steel being utilized. For example, a common weight range for steel coils employed in the electrical equipment industry falls between 5,000 pounds (2,268 kg) and 50,000 pounds (22,680 kg). It should be noted that these dimensions are not fixed and can vary depending on the specific requirements of the electrical equipment industry. Manufacturers may have their own distinct specifications and requirements for the steel coils they utilize in their products.

- Q: How are steel coils used in the production of heating and cooling systems?

- Steel coils are used in the production of heating and cooling systems as they serve as the main component of the heat exchanger. These coils are responsible for transferring thermal energy between the air and the refrigerant, allowing for efficient heat transfer and regulation in the system.

- Q: What are the different methods of cutting steel coils into sheets?

- There are several methods used to cut steel coils into sheets, including shearing, slitting, and laser cutting. Shearing involves using a large, powerful machine to cut through the coil with a straight blade. Slitting involves passing the coil through a set of circular blades that gradually reduce its width, creating multiple narrower sheets. Laser cutting uses a high-powered laser beam to precisely and rapidly cut through the coil, offering a versatile and efficient method.

- Q: Can steel coils be coated with fire-resistant materials?

- Yes, steel coils can be coated with fire-resistant materials.

- Q: How are steel coils used in the production of steel clamps?

- Steel coils are used in the production of steel clamps as they serve as the main raw material for creating the clamps. The steel coils are first processed and transformed into the desired shape and size through cutting, bending, and shaping processes. These coils are then formed into the clamp's body, providing the necessary strength and durability. Overall, steel coils play a crucial role in manufacturing steel clamps by providing the essential material for their construction.

- Q: Hi can someone help me pleaseis there any available data for mechanical behaviour of recycled steel, i need to compare them with new steel.

- Most recycled steel is blended with new steel at the steel mill. Scrap steel that is reused directly doesn't change it properties because it has been used. That is unless it has been in certain environments such as ones with hydrogen, hydrogen sulfide etc. Then the steel can become brittle. You might look for information on the National Association of Corrosion Engineers (NACE). They have lots of information on metals and what causes problems.

Send your message to us

Galvalume STEEL coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords