Fused Silica Bricks - High Quality Refractory Silica Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Shandong, China (Mainland) | Shape: | Brick | Material: | silica |

| SiO2 Content (%): | 94%-96% | Refractoriness (Degree): | Common (1580°< Refractoriness< 1770°) | Brand Name: | ZYC |

Packaging & Delivery

| Packaging Details: | On wooden pallets with plastic films cover |

| Delivery Detail: | According to customers' requirements |

Specifications

1. SiO2 :93%-96%.

2. Can according to customers' requirements.

3. Used for various industrial High temperature kilns.

Silica brick,Refractory silica brick,Silicon brick

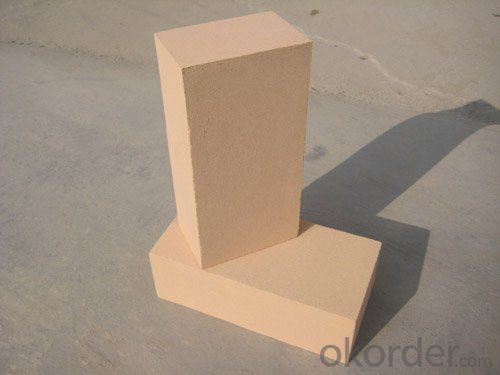

Characteristics:

1. High refractoriness.

2. Have a good fight acid slag erosion ability.

3. High volume stability.

General silica brick: Siliceous refractory products used for various large coke oven, glass kiln stove, hot air stove, etc. | |||

Item | GZ-96 | GZ-95 | GZ-94 |

SiO2 % ≥ | 96 | 95 | 94 |

Fe2O3 % ≤ | 1.0 | 1.2 | 1.4 |

Refractoriness °C ≥ | 1710 | 1710 | 1690 |

Apparent porosity % ≤ | 22 | 22 | 24 |

Cold crushing strength Mpa ≥ | 29.4 | 24.5 | 19.6 |

Refractoriness under load, 0.2MPa, °C ≥ | 1660 | 1650 | 1640 |

True density g/cm3 ≤ | 2.34 | 2.35 | 2.35 |

Silica brick for Hot-blast stove | ||

Item | Dome wall brick | Checker |

SiO2 % ≥ | 95 | 95 |

Cold crushing strength Mpa ≥ | 35 | 30 |

Apparent porosity % ≤ | 22 | 23 |

Creep rate(0.2MPa,1550°C,50h)% ≤ | 0.8 | 0.8 |

True density g/cm3 ≤ | 2.35 | 2.35 |

Thermal expansion(1000 °C)% ≤ | 1.26 | 1.26 |

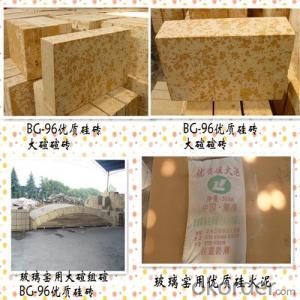

Silica brick for Glass kiln | ||||

Item | BG-96A | BG-96B | BG-95A | BG-95B |

SiO2 % ≥ | 96 | 96 | 95 | 95 |

Fe2O3 % ≤ | 0.8 | 1.0 | 1.2 | 1.2 |

Apparent porosity % ≤ | 22 | 22 | 22 | 22 |

Refractoriness under load, 0.2MPa, °C ≥ | 1680 | 1670 | 1660 | 1650 |

True density g/cm3 ≤ | 2.34 | 2.34 | 2.35 | 2.35 |

Cold crushing strength Mpa ≥ | 30 | 30 | 30 | 30 |

Silica brick for coke oven | ||

Item | Furnace bottom,Furnace wall | Other |

SiO2 % ≥ | 94 | 94 |

Cold crushing strength Mpa ≥ | 30 | 25 |

Apparent porosity % ≤ | 22. | 24 |

Refractoriness under load, 0.2MPa, °C≥ | 1650(Cementation silica 1620) | 1650(Cementation silica 1620) |

Permanent linear Change 1450 °C,2h ≤ | 0—+0.2 | 0—+0.2 |

True density g/cm3 ≤ | 2.34 | 2.35 |

Thermal expansion(1000 °C)% ≤ | 1.28 | 1.30 |

Application:

Silica brick is mainly used for Coke oven, glass kiln, hot-blast stove, tunnel kiln,Acidic furnace non-ferrous metal smelting and some other thermotechnical equipment in good furnace building materials.

- Q: What is the effect of the content of silicon nitride in silicon nitride bonded silicon carbide brick on the use of electrobath? Thank you

- Small fluctuations in the chemical composition do not have a significant effect on use. The key is the operation of the electrolyzer in production to determine whether the side wall will be damaged.

- Q: What is acid refractory?

- Acid refractory material usually refers to refractories with SiO2 content greater than 93%. Its main characteristic is that it can resist acid slag corrosion at high temperature, but it is easy to react with alkaline slag.

- Q: The brick is mainly used in the place?

- Also used for high temperature bearing part of hot blast stove and acid open hearth furnace.

- Q: How to judge the quality of brick, clay brick, high alumina brick furnace from the appearance?

- Mainly from the impurities to determine how much, generally less impurity single color brick.

- Q: The high thermal conductivity of silica brick and traditional brick what is the difference?

- Brick, high thermal conductivity has been greatly improved in terms of morphology, crystal structure, physicochemical index. The structure and morphology of high thermal conductivity of silica brick,Structure and morphology of high thermal conductivity and the traditional brick brick magnified 20 times were compared, high thermal conductivity silica pore size distribution is more uniform and finer.

- Q: Common bond brick?

- When adding ingredients, the amount of lime added shall be converted to CaO, and the amount of addition varies depending on the product, usually fluctuating at 1.5~2.5%. For example, the production of coke oven silica brick, the dosage of CaO is 2.0~3.0%; the production of electric furnace top brick, the dosage of CaO is 1.4~1.75%.

- Q: Why is the highest brick coke oven temperature measuring point temperature not exceeding 1450

- That is because the brick load softening point the maximum temperature is 1450 degrees.

- Q: The chemical composition of silica brick and its physicochemical index?

- The physicochemical index of silica brick:Turn left to |

- Q: What is the silica refractory products?

- Refractory brick with silica content greater than 90%.

- Q: Such purpose and scope please give me detailed points thank you

- Acid refractory brick is mainly composed of tridymite and cristobalite and quartz and a small amount of residual glass phase.

Send your message to us

Fused Silica Bricks - High Quality Refractory Silica Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords