Calcium Silicate Bricks Fumed Silica/ Silicon Dioxide / Nano SiO2 / Silica Fume SiO2 for Concrete, Cement, Mortar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

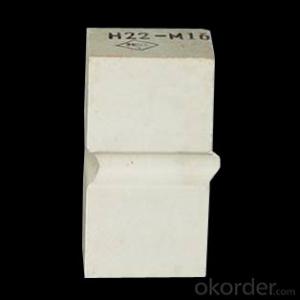

Silicon mortar is adhesive material matched with silica brick. Our silicon mortar has such advantages as high adhesive strength, high refractoriness, excellent refractoriness under load, and good installation performance.

Feature

Control the liquid system, Adhesive, Polymer's rheology and thixotropy.

As additive agent used to prevent subside,thickening and prevent sagging.

Reinforce HRC high temperature sulfuration silicon rubber and RTV-2K room temperature sulfuration silicon rubber.

Improve the quality of the powder, and improve the liquidity and anti-blocking characteristic.

Application

paint and coating, Unsaturated polyester resins, laminating resins and gel coat.

HCR high temperature sulfuration silicon rubber and RTV-2K room temperature sulfuration silicon rubber. Adhesive and fluid sealant, Printing ink, Cable rubber,Plant protection,Food and cosmetics.

Technical Data

| ITEMS | XR-150 | XR-200 |

Form | White powder | White powder |

Whiteness | 98 | 98 |

SiO2 (dry basis) % | ≥99.9 | ≥99.9 |

PH value | 3.5-4.5 | 3.5-4.5 |

BET surface area m2/g | 150±15 | 200±25 |

Bulk density g/L | 40-50 | 40-50 |

Average particle size nm | 14-15 | 14-15 |

Heating loss (105 for 2hr.) % | 0.5-1.0 | 0.5-1.0 |

Ignition loss (1000 for 2hr.) % | 1.0-2.0 | 1.0-2.0 |

package | 10kg/bag | 10kg/bag |

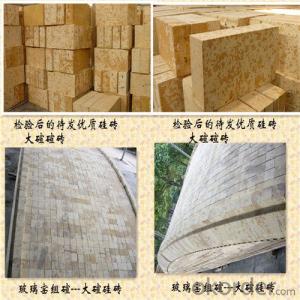

Photos for Workshop

- Q: The introduction of silica brick

- The silica mineral phase is mainly composed of tridymite and cristobalite, there is a small amount of quartz and glass

- Q: Because of the recent relates to this industry, by way of learning to name for all raw materials, I hope knowledgeable friends exhibitions, thank you.

- Classification of chemical components of refractory materialsAccording to the chemical characteristics of refractory raw materials can be divided into acidic refractory materials, such as silica, zircon etc.; neutral refractory raw material, such as corundum, bauxite, mullite (acidic) (acidic), Ge (alkaline) iron and graphite; alkaline refractory materials, such as magnesite, dolomite, magnesium sand calcium sand.

- Q: Why will expand when heated brick

- In the process of SiO2 drying, the four crystalline transformation points of 117, 163, 180~270 and 573 DEG C are found, among which the volume expansion caused by the 180~270 is the largest.

- Q: What is the effect of the content of silicon nitride in silicon nitride bonded silicon carbide brick on the use of electrobath? Thank you

- The main damage of silicon carbide side wall brick is stress damage, not chemical erosion. Chemical damage is formed prior to the formation of the groove, and the damage to the chemical erosion is little after the formation of the groove.

- Q: How much is the highest melting point of silicon?

- Mainly used for partition, carbonization chamber of coke oven and combustion chamber open hearth furnace regenerator and a sediment chamber, soaking furnace, glass melting furnace refractories and ceramic kiln, kiln vault and other load-bearing parts. Also used for high temperature bearing part of hot blast stove and acid open hearth furnace

- Q: Which material is good for furnace refractory?

- Acid refractory with silicon oxide as the main component, are commonly used in brick and clay brick. Silica is silica containing more than 94% silica products, raw materials used in silica, silica and other waste, the acid resistance of slag erosion ability, high load softening temperature, volume shrinkage after repeated burning, or even a slight expansion; but it is vulnerable to the erosion of basic slag, thermal shock resistance is poor. The brick is mainly used for thermal equipment of glass furnace, coke oven, acid furnace etc.. Clay brick with refractory clay as the main raw material, containing 30% to 46% of alumina, weak acid refractory material, heat shock resistance, resistance to acid slag, widely used.

- Q: Why is the three oxidation of two silicon is very harmful impurities in silica brick

- Can generate the material needs is the best way to see the impurity problem!! the first consideration is whether can get the material impurities with what method choice after the time! Miscellaneous reactions cannot have new impurity formation! Selected cannot and need material reaction reagent!

- Q: Can not use it two brick

- The softening temperature is up to 1640~1670 DEG C, and the volume is stable at high temperature for a long time.

- Q: Why in the production of the brick to detect the volume density

- Density is the property of material, different density of materials, density of the same kind of material is not up to standard, affecting performance.

- Q: High temperature refractory material?

- Special materials often use AZS brick (i.e. corundum brick), corundum brick, magnesia chrome bricks, silicon carbide, silicon nitride bonded silicon carbide, nitrides, silicides, sulfide, boride, carbide and other non oxide refractory materials; calcium oxide, chromium oxide, alumina, Magnesium Oxide, beryllium and other refractory materials. Insulation refractories are often used diatomite products, asbestos products, insulation board. Unshaped refractories are often used refractory castable, refractory clay, refractory ramming material, refractory plastic and fettling material, fire resistance, gunning, refractory cast material, fireproof coating, lightweight refractory castable, gun mud.

Send your message to us

Calcium Silicate Bricks Fumed Silica/ Silicon Dioxide / Nano SiO2 / Silica Fume SiO2 for Concrete, Cement, Mortar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords