Full Welded Ball Valve API 6D, ASME Size: 6

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 set

- Supply Capability:

- 3000 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

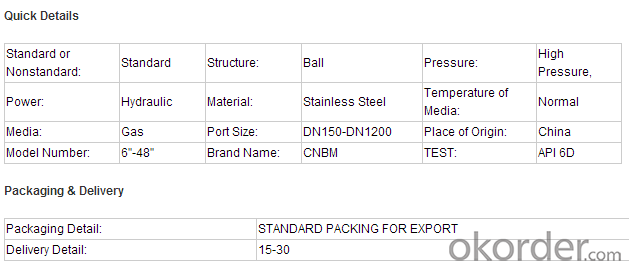

Specifications

Full welded ball valve,

API 6D, ASME;

Size: 6" -48",

ANSI 150LB -1500LB

ANSI B 16.34, API607 and API Q1

Features:

1) Product type: full welded, RTJ/RF flanged,

2) Size range: 6"-48"

3) Pressure classes:

a. ANSI class 150: DN150 -1000 PN20 (NPS6" - 40"),

b. ANSI class 300: DN150-1000 PN50 (NPS6"-40"),

c. ANSI class 400: DN150-1000 PN64 (6"-40"),

d. ANSI class 600: DN150-1200 PN100 (6"-48"),

e. ANSI class 900: DN150-600 PN150 (6"~24")

- Q: DN15 stainless steel ball valve 304 can withstand much pressure?

- All pipe attachments of the same nominal diameter indicated by the same nominal pressure PN have the same connection dimension as the end connection type.GB stainless steel ball valve pressure class PN: 1.6MPa, 2.5MPa, 4.0MPa, 6.4MPa, 10.0MPa and so on. These values correspond to how much stress you can bear.

- Q: DN80/DN100/DN125 how big is the outer diameter of the ball valve flange?

- So you must first determine the pressure level of your ball valve, and then determine the valve flange used standards, and then you can determine the basic parameters of the ball valve flange.

- Q: What does "F" and "C" mean in the Q11F-16C of the ball valve?

- This model is not international standard number, but still can see, of which, F refers to the sealing material: fluorine plastic, C refers to the body material: carbon steel.

- Q: Which is more cost-effective electric ball valve?

- All kinds of Lady valve manufacturers.The company has strong technical force, with adequate and sophisticated machining equipment as the premise, to provide a strong guarantee for the production of high-quality products,

- Q: To help explain the meaning of the ball valve Q11H-16H, combined with the actual, such valves have wood?

- JB T308-2004 valve model preparation method and "GB1048-2005 pipe element nominal pressure definition and selection", there are various types of valve interpretation:Q11H-16HQ: valve type: (Q) ball valve1: connection form: (1) internal thread1: structure form: (1) through flow channelH: sealing surface or lining material: (H) Cr13 stainless steel16: pressure code: (16) 1.6MPaH: body material: (H) Cr13 stainless steel

- Q: Ball valve? I require the valve to control both sides of the liquid, one side with liquid flow, and the other side closed!

- Three way reversing ball valve. Three way ball valves are T and L. The T type can cause three orthogonal pipes to connect with each other and cut off third channels, thus diverting and merging the channels. Two pipeline L three ball type valve can only be connected mutually orthogonal, communicating with each other while maintaining the third pipeline, only as a distribution function.

- Q: What does "2P" ball valve mean?

- The left valve body and the right valve body consist of two parts.

- Q: What are the CF8 and CF3M marks on the stainless steel ball valves?

- Hello, CF8 stands for 304 material, and CF3M stands for 316L material. It's stainless steel

- Q: How to distinguish between single and double ball valve?

- I don't know what you mean by "single" and "double", but the ball valve can be divided into one, two and three.

- Q: DN20 pressure 6000PSI, one piece of thread on the threaded, full diameter ball valve body length and flow hole to how much?

- 3, the flange of the same caliber and cavity size, the premise is to ensure the gate open without collision resistance, but the size and thickness of screw and the number can be determined with reference to the parameters of the same diameter flange. Finally, the point is that in mechanical design, as long as the design is reasonable, there is nothing right or wrong, but it is possible that a design will be more appropriate.

Send your message to us

Full Welded Ball Valve API 6D, ASME Size: 6

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 set

- Supply Capability:

- 3000 set/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches