BALL VALVE of Forging Steel Full-welded API6D/CE/ISO9001 CERTIFIED

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

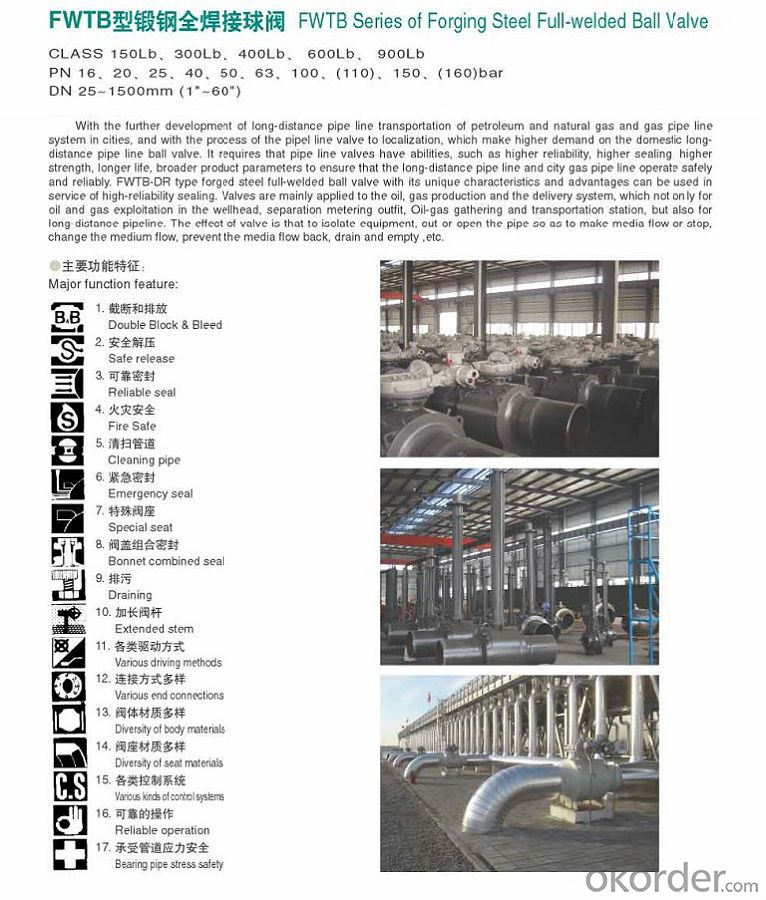

FWTB Series of Forging Steel Full-welded Ball Valve

With the furture development of long-distance pipe line transportation of petroleum an nature gas an gas pipe line system in cities,an with the process of the pipe line valve to localization,which maker higher demand on the dnomestic long-distance pipe line ball valve.FWTB-DR type forged steel full-welded ball valve with itsunique characteristics an advantages can bu used in service of high-reliability sealing.Valves are mainly applied to the oil,gas production and the delivery sytem,which not only for oil and gas exploitation in the wellhead,separation metering outfit,oil-gas gathering and transportation station ,but also for long-distance pipe line.

Design codes anregulations

API:6D/Q1/607/6FA/598/5L

ANSI/ASME

ASME section V/VIII/IX

B16.5/B16.10/B16.25/B16.34/B16.47/B31.8

MSS-SP:SP-6/SP-25/SP-44/SP-45

NACE:MR0175/TM0177

BS 5351

ISO5211

Materrial regulations:

ASTM:A193/A193M/A194/A194M/A313/A313M/A105/A350/A350M/A694/A694M

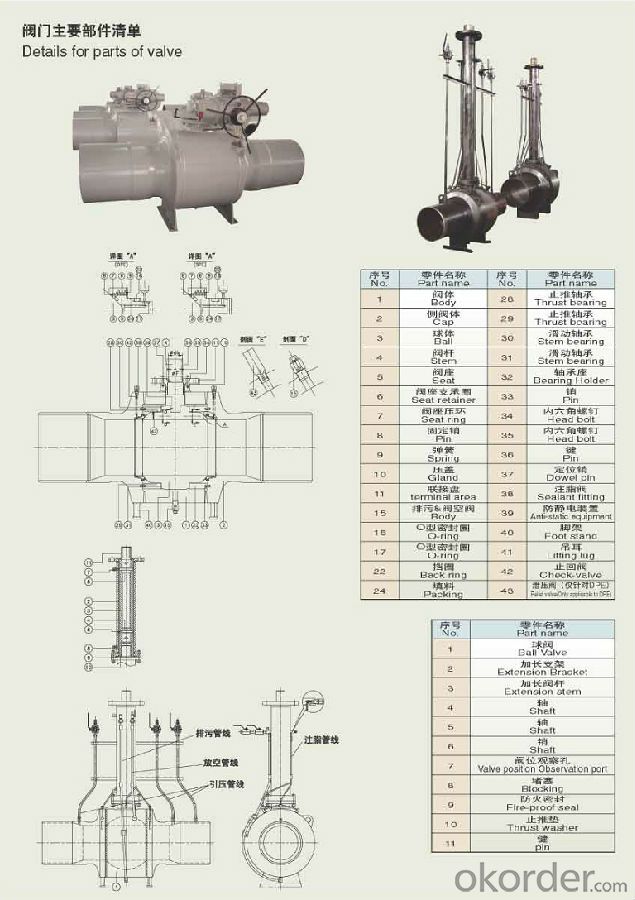

Strukture characteristics

Selection of material

The selection of valve part material conforms to the requirements in regulations of API 6D,ASTM,ASME and etc.

Double Block & Bleed(DBB)

Forging steel structure

Low torque in operation

Reliable sealing

Emergency sealing

Enptying device

Fire Safe

Anti-statc design

Extension stem

Various driving types

The top pad of valve designed according to ISO 5211.

- Q: What are the differences between the pneumatic ball valve and the pneumatic angle seat valve?

- Characteristics of pneumatic ball valve:1. Rotate the spool to make the valve clear or closed.2 pneumatic valve switch light, small size,3. It can be made into big caliber,4 、 reliable sealing, simple structure, convenient maintenance,5, sealing surface and spherical surface often in closed state, it is not easy to be medium erosion.

- Q: What does "DN25 Q41F46-16C" mean?

- DN is nominal diameter, nominal diameter (or nominal diameter), that is, all kinds of pipe and pipe accessories of general diameter of 25 mm

- Q: What do you mean by ball valves dn20pn1.6rf?

- DN20 caliber is 20mmPN is the pressure grade, usually PN16, 1.6MPa classRF convex flange connectionYour side should be similar to the Q41F-16 model of this type of ball valve

- Q: Ask you engineer, 150mm diameter ball valve or butterfly valve, installed in the water supply pipe, water pressure 0.4Mpa, driven by the electric actuator, should much force distance?Sincere thanks, enthusiastic support of net friend.

- Reference: ball valve 1000N on the line, butterfly 250N canThis valve with the switch torque is related, each manufacturer according to the workmanship, process switching torque is not the same.You can refer to the recommended value of the actuator manufacturer

- Q: What does "ball Q41F-16" mean?

- Q- ball, 4- flange connection, 1- DC channel, floating ball, F- sealing material for fluorine plastic, 16- nominal pressure of 16 kg, the valve body material for gray cast iron. If you want to know the details of the valve named model establishment, can refer to the JBT-308-2004 standard.

- Q: Is a plastic ball valve, connecting France is hot melt.

- Visible, electric ball valve in daily life, industrial manufacturing and other fields have great application and market space. With the development of the times, the electric valve also put forward higher requirements, such as digital remote control, so the development of this industry, cannot do without the progress of technology, from the past to the ordinary valve electric valve electric valve to now, by the digital intelligent valve, look first to the application of new technology on the product rapidly the transformation and development of new products to meet market demand.

- Q: I design water meter transformation, 50WPD table, the original table before the installation of 50 anti-theft valve, table after the installation of 50 of the globe valve; master let me put anti-theft valve into anti-theft gate valve. Switch the stop valve to the gate valve. I'd like to ask what kind of valve is appropriate Why? And I checked from the Internet that the ball valve is generally used for small aperture, this aperture range is how much? Why?No copy paste, thank you......

- First, the advantages and disadvantages of the ball valve1, advantages:Minimum flow resistance (actual 0);Because it is not stuck at work (without lubricant), it can be reliably applied to corrosive media and low boiling liquid;Complete sealing can be achieved in larger pressure and temperature range;It can realize quick opening and closing, and the opening and closing time of some structures is only 0.05~0.1s, so that it can be used in the automation system of the test stand. Quick opening and closing valve, operation without shock;The spherical closure can be automatically positioned at the boundary position;The working medium in the two-sided reliable seal;In the fully open and fully closed, the ball and seat sealing surface and the dielectric isolation, the high-speed media through the valve sealing surface will not cause erosion;It has the advantages of compact structure, light weight, it could be considered for most reasonable structure of the valve system of medium low temperature;To body symmetry, especially the welded body structure, can well withstand the stress from the pipe;The closure of parts can withstand the pressure differential.11;They all welded ball valve can be buried underground, so that the valve parts from erosion, the maximum life of up to 30 years, is the most ideal oil and natural gas pipeline valve.

- Q: For example, how many sizes and pressures are used in the two piece?

- First of all, the difference between a ball valve and two chip, three chip ball valve is a ball valve flow, the internal structure of the necking design belongs to the design, the same diameter ball valve products must be smaller than the other two kinds of ball valves flow more. Compression capacity is not as good as two, but better than the three chip. A ball valve has the advantages of low cost, low price; the two valve is the three products in the most excellent in resistance and flow, the valve inside is preferred; features three ball valve design structure is easy to install, because the three ball valve can be installed by dismantling during installation, so in different pipeline even some other connections are completely no problem, fast loading, thread, flange, welding and so on, so the market is the most complete connection number of ball valve, especially when welding, a chip ball valve and the two valve can not be opened due to installation, want to welding in the pipeline it would be easy to the inside of the PTFE (similar to plastic) in a burnt out, the best choice at this time is three piece ball valve. But the disadvantage of three piece ball valve is the poor compression ability.

- Q: Our factory has part of the ball valve in the direction of movement and normal ball valve is the opposite direction: anti clockwise for the turn off, clockwise. Excuse me, what's the reason for this?Excuse me, is this because the valve body installs the reason of the contrary or the reason, the ball valve is thus designed?Are there any positive and negative points when the ball valve is installed?

- Ordinary ball valve is the reverse turn off, the general ball valve without direction requirements. Each kind has the direction request, generally has the arrow or the nameplate explanation on the valve body.

- Q: What does copper ball valve mean by "1/2"?

- 1/2 is inch inch, which is what is usually called "valve", and the caliber is "DN15". You can see the contrast chart of the valve diameter and inch.

Send your message to us

BALL VALVE of Forging Steel Full-welded API6D/CE/ISO9001 CERTIFIED

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords