FRP Pultrusion Profiles - Pultruded Molded Gratings with High Strength and Corrosion Resistance

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m

- Supply Capability:

- 30000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

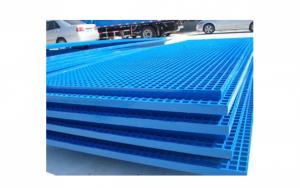

Pultruded grating is made by a particular assembly process, which using “I” shape as its main load-bearing and special rod to go through the bearing bar. Pultruded grating include the standard grating and the custom grating, the custom grating can be designed to meet customer’s requirement or special using condition by changing the shape, size and space of the bearing bars, the surface can be covered with lozenge panel, grit panel, or added the anti-slippery sand directly.

FRP pultruded grating has the most characteristics of molded grating, but it has its distinct advantages, it has very high fiberglass content in the loading direction, so it has very high load capability, it has more superiority when used at wide span, so that the basic support will be decreased and the project cost will be reduced accordingly.

FEATURES

a. anti-corrosion, non-rusty

b. lightweight and high strength

c. anti-flammable

d. anti-fatigue

e. anti-slippery and safety

f. anti-ageing

g. easy to installation and maintenance

h. excellent electromagnetism property

DETAILED PARAMETER TABLE

Thickness (mm) | Bar width (mm) | Openspace (mm) | Open rate (%) | Approx weight (kg/m 2 ) |

25.4 | 15.2 | 22.8 | 60 | 13.2 |

25.4 | 15.2 | 15.2 | 50 | 15.9 |

25.4 | 15.2 | 10.1 | 40 | 18.5 |

25.4 | 40 | 10.8 | 21 | 14.5 |

38.1 | 15.2 | 22.8 | 60 | 15.8 |

38.1 | 15.2 | 15.2 | 50 | 19.1 |

38.1 | 15.2 | 10.1 | 40 | 22.4 |

50.8 | 25.4 | 25.4 | 50 | 16.6 |

50.8 | 25.4 | 12.7 | 33 | 21.1 |

PICTURES

- Q: What does M23 grade of glass fiber reinforced plastic section mean?

- There are many kinds of FRP Pultruded Shapes, such as glass fiber reinforced plastic round tube, glass fiber reinforced plastic square tube, glass fiber reinforced plastic rectangular tube, glass fiber reinforced plastic round bar, glass fiber reinforced plastic i-beam.

- Q: Can FRP pultrusion profiles be used in the transportation and logistics industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the transportation and logistics industry. FRP pultrusion profiles offer several advantages that make them suitable for various applications in this industry. Firstly, FRP pultrusion profiles are lightweight yet extremely strong and durable. This makes them ideal for use in transportation vehicles, such as trucks, trailers, and containers, where reducing weight is crucial for improving fuel efficiency and reducing emissions. Despite their lightweight nature, FRP pultrusion profiles can withstand heavy loads and harsh environmental conditions, ensuring their reliability and longevity. Secondly, FRP pultrusion profiles are highly corrosion-resistant. Unlike traditional materials, such as steel or aluminum, FRP does not rust or corrode when exposed to moisture or chemicals. This makes FRP profiles suitable for use in transportation and logistics applications that involve exposure to corrosive substances, such as saltwater, chemicals, or acidic environments. By using FRP pultrusion profiles, companies can reduce maintenance costs associated with corrosion and prolong the lifespan of their equipment. Additionally, FRP pultrusion profiles offer design flexibility. They can be manufactured in various shapes, sizes, and configurations to meet the specific requirements of transportation and logistics applications. Whether it is for structural components, platforms, flooring, or supports, FRP profiles can be customized to fit different needs, ensuring optimal performance and functionality. Moreover, FRP pultrusion profiles have excellent electrical and thermal insulation properties. This makes them suitable for applications where electrical conductivity needs to be minimized or thermal insulation is required. In the transportation and logistics industry, this can be beneficial for applications such as insulation for refrigerated containers or electrical insulation for specialized vehicles. In summary, FRP pultrusion profiles are well-suited for the transportation and logistics industry. Their lightweight, strong, durable, corrosion-resistant, and customizable nature, along with their electrical and thermal insulation properties, make them a reliable choice for various applications in this sector.

- Q: Are FRP pultrusion profiles resistant to sulfuric acid?

- FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to sulfuric acid. The corrosion resistance of FRP profiles is one of their key advantages compared to traditional materials like steel or concrete. Sulfuric acid is a highly corrosive substance, but FRP pultrusion profiles can withstand its effects due to the inherent properties of the composite materials used in their construction. The corrosion resistance of FRP profiles is mainly attributed to the resin matrix that encapsulates the reinforcing fibers. Most commonly used resins in pultrusion, such as polyester, vinyl ester, or epoxy, have excellent chemical resistance properties, including resistance to sulfuric acid. However, it is important to note that the resistance of FRP pultrusion profiles to sulfuric acid can vary depending on several factors. The concentration and temperature of the acid, as well as the specific resin formulation used in the profile, can influence the overall resistance. In highly concentrated or elevated temperature environments, it is advisable to consult with the manufacturer or supplier to ensure the specific FRP profile meets the required resistance level. In general, FRP pultrusion profiles offer a high level of resistance to sulfuric acid, making them suitable for various applications in industries where this corrosive substance may be present, such as chemical processing, wastewater treatment, or mining.

- Q: Can FRP pultrusion profiles be used in water treatment plants?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in water treatment plants. FRP pultrusion profiles offer several advantages that make them well-suited for use in this industry. Firstly, FRP pultrusion profiles are highly corrosion resistant. Water treatment plants often have aggressive environments with exposure to chemicals and moisture, which can cause corrosion and degradation of traditional materials like steel. However, FRP pultrusion profiles are immune to corrosion, making them an ideal choice for water treatment applications. Secondly, FRP pultrusion profiles have excellent strength-to-weight ratios. This means that they provide high structural integrity while being lightweight, making them easier to handle and install in water treatment plants. Additionally, their high strength allows them to withstand the loads and pressures typically encountered in these environments. Furthermore, FRP pultrusion profiles are electrically non-conductive. This is particularly advantageous in water treatment plants, where there may be a need to isolate electrical equipment or components to prevent short circuits and protect personnel. FRP profiles provide a safe and reliable solution in such cases. Lastly, FRP pultrusion profiles have a long service life with minimal maintenance requirements. They do not rot, rust, or corrode, ensuring durability and longevity even in harsh water treatment conditions. This reduces downtime and maintenance costs, making FRP profiles a cost-effective choice for water treatment plant applications. Overall, FRP pultrusion profiles are an excellent choice for use in water treatment plants due to their corrosion resistance, high strength-to-weight ratio, electrical non-conductivity, and long service life. Their use can contribute to improved efficiency, reduced maintenance, and increased durability in water treatment processes.

- Q: Are FRP pultrusion profiles resistant to fungi and mold?

- Yes, FRP pultrusion profiles are highly resistant to fungi and mold. The combination of the materials used in FRP (Fiber Reinforced Polymer) and the manufacturing process make them inherently resistant to biological growth. This makes FRP pultrusion profiles a durable and low-maintenance solution in environments prone to fungal and mold growth.

- Q: Can FRP pultrusion profiles be used in the automotive manufacturing industry?

- Certainly! Fiber Reinforced Polymer (FRP) pultrusion profiles have the potential to be utilized within the automotive manufacturing sector. These profiles possess a number of advantages that render them appropriate for automotive applications. To begin with, one of the key benefits of FRP profiles is their lightweight nature, which aids in reducing the overall weight of vehicles. This is of utmost importance in enhancing fuel efficiency and decreasing emissions. Moreover, the reduced weight of FRP profiles enables improved handling and enhanced performance. Additionally, FRP profiles exhibit exceptional mechanical properties, including high strength and stiffness. These properties make them well-suited for integration into structural components of vehicles, such as chassis, body panels, and frames. FRP profiles are able to withstand heavy loads and offer excellent impact resistance, thereby ensuring the safety of both the vehicle and its occupants. Furthermore, FRP profiles possess outstanding corrosion resistance, a quality that is particularly advantageous in automotive applications. In contrast to traditional materials like steel, FRP profiles are impervious to rust and corrosion. Consequently, they are ideally suited for deployment in various automotive environments, including those that involve exposure to moisture, chemicals, and salt. Moreover, FRP pultrusion profiles can be customized to meet specific design requirements, thereby affording flexibility in the manufacturing process. They can be produced in a range of shapes and sizes, which allows for the design of intricate components. This design flexibility also permits customization and optimization of vehicle performance. Lastly, FRP profiles possess excellent thermal and electrical insulation properties. This renders them appropriate for applications where minimizing electrical conductivity or providing thermal insulation is necessary. On the whole, the combination of the lightweight nature, high strength, corrosion resistance, design flexibility, and insulation properties of FRP pultrusion profiles positions them as an ideal choice for deployment within the automotive manufacturing industry. Their usage can contribute to the development of more efficient, safe, and durable vehicles.

- Q: Can FRP pultrusion profiles be used in mining applications?

- Yes, FRP pultrusion profiles can be used in mining applications. FRP (Fiber Reinforced Polymer) pultrusion profiles offer excellent strength-to-weight ratio, corrosion resistance, and durability, making them suitable for various mining applications such as support structures, ventilation systems, walkways, and equipment enclosures. Additionally, FRP profiles are non-conductive and non-magnetic, making them ideal for underground mining environments.

- Q: Are pultruded FRP sections strong? What are its main areas of application?

- General and environmental units of manhole covers, factories and mines units of insulated cable tray; chemical units of the transmission pipeline; insulation protection fence; including floor and so on.

- Q: Can FRP pultrusion profiles be used in the construction of agricultural structures?

- Yes, FRP pultrusion profiles can be used in the construction of agricultural structures. FRP pultrusion profiles are lightweight, durable, and resistant to corrosion, making them suitable for various agricultural applications such as greenhouse framing, livestock enclosures, and storage sheds. They offer excellent strength-to-weight ratio and can withstand harsh environmental conditions, making them a reliable choice for agricultural construction.

- Q: Can FRP pultrusion profiles be used in walkway systems?

- Yes, FRP pultrusion profiles can be used in walkway systems. FRP pultrusion profiles are lightweight, strong, and resistant to corrosion, making them suitable for use in various applications, including walkways. They offer durability, low maintenance, and can withstand heavy loads, making them a reliable choice for walkway systems.

Send your message to us

FRP Pultrusion Profiles - Pultruded Molded Gratings with High Strength and Corrosion Resistance

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m

- Supply Capability:

- 30000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords