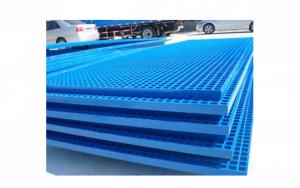

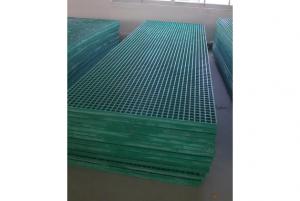

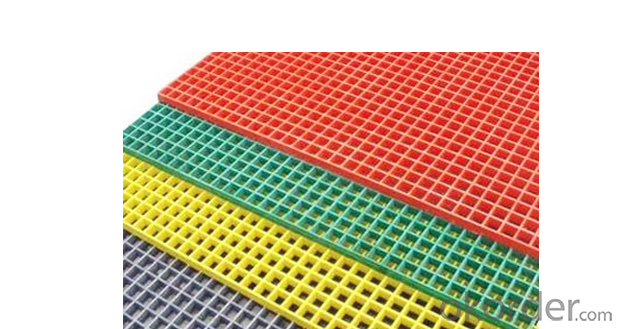

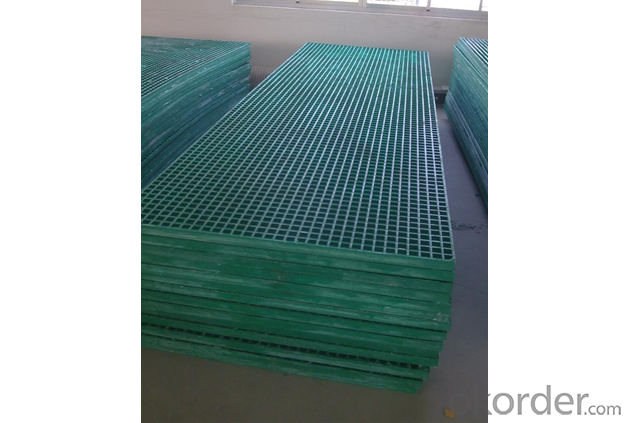

FRP Pultrusion Profiles - High Strength, Corrosion & Fire Resistant Fiberglass Grating for Walkway and Trench Cover

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

Corrosion Resistance

Fire Resistance

Light Weight & High Strength

- Aging Resistance

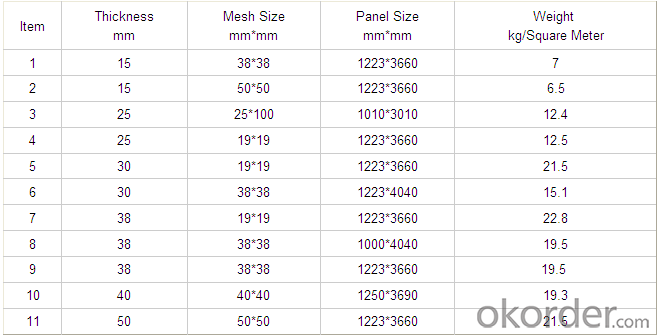

Specification

Advantage

coated with prevent aging layer

excellent insulating performance

- easy installation

Application

Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

- Pool railings in sewage treatment industry

Corrosive chemical industry equipment around the fence

All kinds of building maintenance section

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

3. How is the package?

Usually, we arrange the standard out-package for exporting.

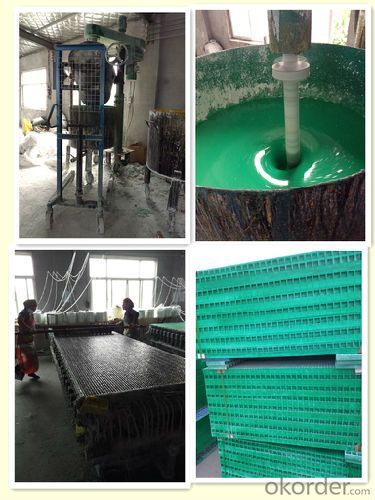

PROCESS

FACTORY

- Q: Can FRP pultrusion profiles be used in modular construction?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can definitely be used in modular construction. FRP profiles are lightweight, high-strength, corrosion-resistant, and have excellent thermal and electrical insulating properties. These characteristics make them ideal for use in modular construction, where the emphasis is on prefabrication, transportation, and rapid assembly. The use of FRP pultrusion profiles in modular construction offers several advantages. First, their lightweight nature makes them easy to handle and transport, reducing logistical costs and effort. Second, their high strength-to-weight ratio ensures structural integrity while minimizing the overall weight of the modular components. This is particularly beneficial in applications where weight reduction is crucial, such as rooftop installations or areas with limited load-bearing capacity. Furthermore, the corrosion resistance of FRP profiles eliminates the need for regular maintenance and extends the lifespan of the modular construction. This is particularly advantageous in harsh environments, such as coastal areas or chemical processing facilities, where traditional construction materials like steel may deteriorate quickly. Additionally, FRP pultrusion profiles can be easily customized to meet specific design requirements. They can be manufactured in various shapes, sizes, and colors, allowing for flexibility in modular construction design. The profiles can also be easily integrated with other construction materials, such as concrete or wood, providing compatibility with existing modular systems. In summary, FRP pultrusion profiles are highly suitable for modular construction due to their lightweight, high strength, corrosion resistance, and customization capabilities. Their use in modular construction can enhance efficiency, reduce costs, and improve the overall performance and durability of modular buildings and structures.

- Q: Can FRP pultrusion profiles be used in the renewable energy sector?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be effectively used in the renewable energy sector. These profiles possess excellent strength-to-weight ratio, corrosion resistance, and durability, making them ideal for various renewable energy applications. They can be utilized in the manufacturing of wind turbine blades, solar panel frames, structural components for hydroelectric power systems, and much more. Additionally, FRP pultrusion profiles offer design flexibility, allowing for customization to specific project requirements.

- Q: Can FRP pultrusion profiles be used in the water treatment industry?

- Yes, FRP pultrusion profiles can be used in the water treatment industry. FRP (Fiber Reinforced Polymer) pultrusion profiles are known for their excellent corrosion resistance, high strength, and durability. These properties make them suitable for various applications in the water treatment industry. FRP pultrusion profiles can be used in the construction of water treatment tanks, pipes, and other infrastructure. They are resistant to chemicals, including the harsh chemicals often used in water treatment processes. This corrosion resistance ensures a longer lifespan for the equipment and reduces maintenance costs. Additionally, FRP pultrusion profiles have a high strength-to-weight ratio, making them ideal for applications that require lightweight yet strong materials. This allows for easier installation and transportation of water treatment equipment. Furthermore, FRP pultrusion profiles offer design flexibility. They can be manufactured in various shapes and sizes to meet specific project requirements. This allows for customization and optimization of water treatment systems, ensuring efficient and effective water treatment processes. Overall, FRP pultrusion profiles are a reliable and cost-effective choice for the water treatment industry. They provide excellent corrosion resistance, high strength, and design flexibility, making them suitable for various applications in water treatment systems.

- Q: Can FRP pultrusion profiles be used in telecommunications towers?

- Telecommunications towers can indeed utilize FRP (Fiber Reinforced Polymer) pultrusion profiles. These profiles possess several advantageous features that render them suitable for this particular application. Firstly, FRP profiles possess a lightweight yet robust nature, facilitating effortless installation and reducing the overall structural weight of telecommunications towers. This characteristic is crucial as it aids in minimizing the burden imposed on the tower structure. Secondly, FRP pultrusion profiles exhibit exceptional resistance to corrosion, making them ideally suited for outdoor applications such as telecommunications towers that are constantly exposed to diverse environmental conditions. Unlike conventional materials like steel or wood, FRP profiles do not succumb to rust, rot, or deterioration when subjected to moisture, UV radiation, or chemicals typically encountered in outdoor environments. Additionally, FRP pultrusion profiles offer excellent electrical insulation properties, a critical aspect for telecommunications towers. These profiles are non-conductive, thereby reducing the likelihood of electrical interference or short circuits that might disrupt the tower's communication systems. Moreover, FRP pultrusion profiles can be produced in various shapes and sizes, thereby enabling customization and meeting the specific design requirements of telecommunications towers. This versatility facilitates seamless integration and compatibility with other components of the tower. Overall, the combination of lightweight composition, high strength, corrosion resistance, electrical insulation, and customization options renders FRP pultrusion profiles an advantageous and viable selection for utilization in telecommunications towers.

- Q: Are FRP pultrusion profiles resistant to termites or other pests?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to termites and other pests. The composition of FRP, which includes resin and glass fibers, makes it an inhospitable material for pests. Unlike wood, FRP does not provide a food source or favorable conditions for termites or other pests to thrive. Therefore, FRP pultrusion profiles are an excellent choice for applications where resistance to pests is required.

- Q: Are FRP pultrusion profiles resistant to high-pressure water jets?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to high-pressure water jets. The inherent properties of FRP, such as its high strength-to-weight ratio, corrosion resistance, and durability, make it a suitable material for applications involving exposure to water and other harsh environments. The manufacturing process of pultrusion ensures that the fibers are thoroughly impregnated with resin, resulting in a homogeneous and highly dense composite material. This density provides FRP pultrusion profiles with a high resistance to water penetration, preventing the material from being damaged or compromised by high-pressure water jets. Furthermore, FRP pultrusion profiles are known for their excellent chemical resistance, which includes resistance to water. This characteristic ensures that the profiles will not degrade or deteriorate when exposed to high-pressure water jets over extended periods. It is worth noting that the specific resistance of FRP pultrusion profiles to high-pressure water jets may vary based on the specific resin and fiber combination used in their manufacturing. Therefore, it is recommended to consult the manufacturer or supplier for detailed information regarding the resistance of specific FRP pultrusion profiles to high-pressure water jets in a given application.

- Q: Are FRP pultrusion profiles resistant to vibration or shock?

- FRP pultrusion profiles are highly resistant to vibration and shock. The inherent properties of FRP (Fiber Reinforced Polymer) materials make them ideal for applications requiring durability and strength under dynamic loading conditions. The composition of FRP profiles, which typically include a combination of reinforcing fibers and a resin matrix, provides excellent stiffness and damping characteristics. This enables FRP pultrusion profiles to effectively absorb and dissipate vibrations and shock forces, preventing damage or degradation. Additionally, the design flexibility of FRP allows for tailored reinforcement and optimization, further enhancing its resistance to vibration and shock. Therefore, FRP pultrusion profiles are a reliable choice for applications where these properties are crucial, such as in aerospace, automotive, marine, and structural engineering industries.

- Q: Are FRP pultrusion profiles resistant to chemicals used in food packaging?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to chemicals used in food packaging. FRP materials are known for their excellent resistance to a wide range of chemicals, including those commonly used in food packaging such as acids, bases, solvents, and oils. This chemical resistance makes FRP pultrusion profiles a suitable choice for applications involving contact with food packaging materials. However, it is important to note that the specific resistance of FRP profiles may vary depending on the formulation and type of resin used. Therefore, it is advisable to consult with the manufacturer or supplier to ensure that the chosen FRP pultrusion profiles are suitable for the specific chemicals used in the food packaging industry.

- Q: Can FRP pultrusion profiles be used in the construction of highway guardrails?

- Yes, FRP pultrusion profiles can be used in the construction of highway guardrails. FRP (Fiber Reinforced Polymer) pultrusion profiles offer excellent strength-to-weight ratio, corrosion resistance, and durability, making them a suitable choice for guardrails. They are lightweight, easy to install, and require minimal maintenance, making them cost-effective in the long run. Additionally, FRP profiles can be molded into various shapes and sizes to meet specific design requirements, ensuring the safety and effectiveness of the highway guardrails.

- Q: Are FRP pultrusion profiles resistant to moisture absorption?

- Yes, FRP pultrusion profiles are highly resistant to moisture absorption. The inherent properties of the fiberglass and resin used in pultrusion manufacturing make the profiles highly durable and impervious to moisture, ensuring long-term performance and minimal structural damage.

Send your message to us

FRP Pultrusion Profiles - High Strength, Corrosion & Fire Resistant Fiberglass Grating for Walkway and Trench Cover

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords