FRP Pultrusion Profiles - Fiberglass Profile C

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 20000m m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specifications

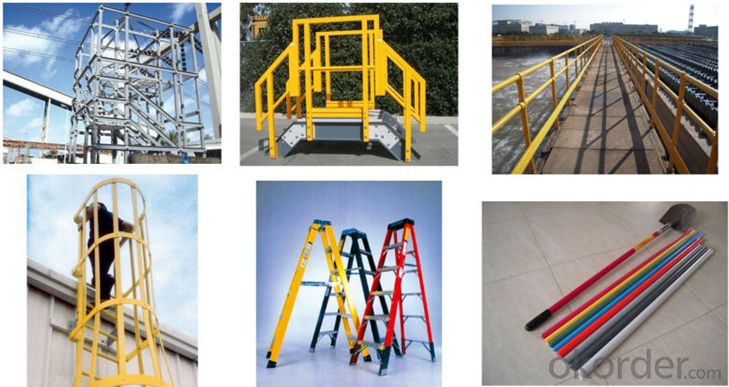

fiberglass mesh grating

1.meet ASTM E-84 AND ISO9001

2.anti-corrosion floor

3.anti-conductive

4.walkway,platform,trench cove

fiberglass mesh grating

Corrosion and Chemical resistant;Slip-resistant ;High strength-to-weight ratio;Ergonomic ;Low maintenance ;Fire retardant ;Easily fabricated and installed

- Q: How do FRP pultrusion profiles perform in high-vibration applications?

- FRP pultrusion profiles perform exceptionally well in high-vibration applications. Due to their inherent structural properties, including high strength-to-weight ratio and excellent fatigue resistance, they can effectively withstand and dampen vibrations without compromising their integrity or performance. Additionally, their non-corrosive nature makes them ideal for long-term use in high-vibration environments, providing enhanced durability and reliability.

- Q: Can FRP pultrusion profiles be used in the construction of railway sleepers?

- The use of FRP (Fiber Reinforced Polymer) pultrusion profiles is indeed possible in the construction of railway sleepers. These profiles possess a range of advantages that render them suitable for this particular application. To begin with, the lightweight yet robust nature of FRP pultrusion profiles makes them an ideal option for railway sleepers. They boast high strength-to-weight ratios, enabling them to withstand heavy loads and reliably support the weight of trains. Moreover, their lightweight constitution facilitates transportation and installation, thereby reducing construction time and costs. Additionally, FRP pultrusion profiles exhibit a high resistance to corrosion, a crucial aspect for railway sleepers. Unlike traditional materials such as wood or steel that are prone to corrosion when exposed to moisture and chemicals, FRP profiles are non-corrosive. Consequently, they do not necessitate regular maintenance or replacement due to rust or decay. Furthermore, these profiles offer exceptional durability and longevity. They can withstand UV radiation, extreme temperatures, and chemicals, ensuring a longer lifespan compared to conventional materials. As a result, the need for frequent replacements is minimized, leading to reduced maintenance and lifecycle costs. Moreover, FRP pultrusion profiles can be tailored to meet specific design requirements. They can be manufactured in various shapes and sizes to accommodate different railway sleeper designs, providing flexibility in construction. Additionally, they can be produced in different colors, allowing for aesthetic customization. Lastly, FRP pultrusion profiles possess excellent electrical insulation properties, a critical factor for railway sleepers. They are capable of providing insulation between the train tracks and the ground, preventing electrical interference and ensuring safe operation. In conclusion, FRP pultrusion profiles are a suitable choice for constructing railway sleepers due to their lightweight yet strong composition, corrosion resistance, durability, customization options, and electrical insulation properties.

- Q: Are FRP pultrusion profiles resistant to mold and mildew?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles are generally resistant to mold and mildew. FRP is a composite material made of a polymer matrix reinforced with fibers, typically glass fibers. Unlike organic materials such as wood or traditional plastics, FRP does not provide a suitable environment for mold and mildew growth. The inherent properties of FRP, such as its non-porous nature and resistance to moisture absorption, make it highly resistant to mold and mildew. Additionally, FRP pultrusion profiles are often manufactured with a smooth and glossy surface, which further inhibits the growth of mold and mildew. Furthermore, FRP is chemically inert, meaning it does not react with most substances. This characteristic makes FRP profiles highly resistant to chemical attacks, including those that may promote the growth of mold and mildew. As a result, FRP pultrusions are commonly used in environments where moisture and humidity are present, such as bathrooms, swimming pools, and outdoor applications. However, it is important to note that while FRP is resistant to mold and mildew, it is not completely immune. In certain extreme conditions, where moisture levels are consistently high and proper maintenance is neglected, mold and mildew growth may still occur. Regular cleaning and maintenance are recommended to ensure the longevity and resistance of FRP pultrusion profiles to mold and mildew.

- Q: Can FRP pultrusion profiles be used in chemical storage tanks?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in chemical storage tanks. FRP pultrusion profiles are known for their excellent corrosion resistance, making them suitable for storing a wide range of chemicals. They are also lightweight, strong, and have a high strength-to-weight ratio, which makes them an ideal choice for constructing durable and long-lasting chemical storage tanks. Additionally, FRP pultrusion profiles can be customized to meet specific design requirements, allowing for flexibility in tank design and construction. Overall, FRP pultrusion profiles are a reliable and cost-effective option for chemical storage tanks due to their corrosion resistance, strength, and customization capabilities.

- Q: Can FRP pultrusion profiles be used in infrastructure projects?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in infrastructure projects. FRP pultrusion profiles offer several advantages over traditional materials such as steel and concrete. Firstly, FRP profiles are lightweight, yet still possess high strength-to-weight ratios. This makes them easier to transport and install, reducing construction time and costs. Additionally, their lightweight nature ensures they do not exert excessive loads on the supporting structures. Secondly, FRP profiles are corrosion-resistant. Unlike steel, FRP does not rust or corrode when exposed to harsh environmental conditions, making them ideal for infrastructure projects located in coastal areas or regions with high humidity. This corrosion resistance extends the service life of the structures and reduces maintenance requirements, resulting in long-term cost savings. Thirdly, FRP pultrusion profiles offer excellent durability and dimensional stability. They are highly resistant to fatigue, creep, and environmental degradation, ensuring the longevity and structural integrity of the infrastructure. Their dimensional stability also means that they maintain their shape and structural properties over time, reducing the risk of deformation or failure. Furthermore, FRP profiles can be customized to meet specific project requirements. They can be manufactured in various shapes, sizes, and strengths, allowing for versatile applications in infrastructure projects such as bridges, walkways, railings, support structures, and utility poles. Overall, the use of FRP pultrusion profiles in infrastructure projects offers numerous advantages, including lightweight construction, corrosion resistance, durability, and customization options. These benefits make FRP profiles a viable and cost-effective alternative to traditional materials for various infrastructure applications.

- Q: Can FRP pultrusion profiles be used in cooling towers?

- Yes, FRP pultrusion profiles can indeed be used in cooling towers. FRP (Fiber Reinforced Polymer) pultrusion profiles offer excellent corrosion resistance, lightweight construction, and high strength, making them ideal for cooling tower applications. These profiles can withstand the harsh environmental conditions typically found in cooling towers, such as exposure to chemicals, moisture, and temperature variations. Additionally, FRP pultrusion profiles are easy to install, require minimal maintenance, and have a long service life, making them a cost-effective choice for cooling tower construction.

- Q: Can FRP pultrusion profiles be used in renewable energy projects?

- Certainly, FRP pultrusion profiles are capable of being used in renewable energy projects. They possess a wide range of advantages that make them suitable for various applications within the renewable energy sector. To begin with, FRP pultrusion profiles are both lightweight and strong, which makes them ideal for utilization in wind turbine blades. The lightweight nature of FRP materials allows for increased efficiency in wind energy generation by reducing the load on the turbine, thus enhancing overall performance. Furthermore, the high strength-to-weight ratio of FRP profiles ensures durability and longevity, even in severe environmental conditions. Additionally, FRP pultrusion profiles display exceptional resistance to corrosion, which renders them suitable for employment in solar panel mounting structures and other components exposed to moisture and outdoor elements. This corrosion resistance ensures that FRP profiles maintain their structural integrity and performance over an extended period, diminishing the need for frequent maintenance and replacement. Furthermore, FRP pultrusion profiles can be customized to meet specific project requirements, providing flexibility in design and functionality. They can be easily molded into complex shapes and sizes, facilitating the creation of innovative and efficient solutions for renewable energy projects. Moreover, FRP materials are non-conductive and possess excellent electrical insulation properties, making them suitable for use in electrical enclosures and support structures for renewable energy systems such as solar power plants. In conclusion, FRP pultrusion profiles can be effectively utilized in renewable energy projects due to their lightweight, strong, corrosion-resistant, customizable, and electrically-insulating properties. These characteristics make FRP profiles a reliable and sustainable choice for various applications within the renewable energy sector.

- Q: Can FRP pultrusion profiles be used in electrical insulation applications?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in electrical insulation applications. FRP profiles offer excellent electrical insulation properties, making them suitable for a wide range of electrical applications. The high dielectric strength of FRP materials ensures that electrical currents are effectively contained within the desired pathways, preventing leakage and electrical hazards. Additionally, FRP profiles possess low electrical conductivity, reducing the risk of electrical shorts and improving overall safety in electrical insulation applications. The non-magnetic nature of FRP materials is also advantageous, as it eliminates the possibility of electromagnetic interference (EMI) in sensitive electrical systems. Furthermore, FRP pultrusion profiles are lightweight, corrosion-resistant, and have a long service life, making them a cost-effective and durable solution for electrical insulation applications.

- Q: Are FRP pultrusion profiles electrically conductive?

- No, FRP pultrusion profiles are not electrically conductive.

- Q: Can FRP pultrusion profiles be used in cooling towers?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in cooling towers. FRP pultrusion profiles offer several advantages that make them suitable for cooling tower applications. Firstly, FRP pultrusion profiles have excellent corrosion resistance, which is essential in a cooling tower environment where exposure to water and chemicals is common. Unlike traditional materials like steel, FRP pultrusion profiles do not rust or corrode, ensuring longer service life and reduced maintenance costs. Secondly, FRP pultrusion profiles have high strength-to-weight ratio, making them lightweight yet strong enough to withstand the structural requirements of cooling towers. This allows for easier installation and transportation, reducing overall project costs. Thirdly, FRP pultrusion profiles have excellent thermal insulation properties. Cooling towers involve the transfer of heat from water to the surrounding air, and the thermal insulation provided by FRP pultrusion profiles helps enhance the efficiency of the cooling process. Lastly, FRP pultrusion profiles are highly customizable and can be designed to meet specific requirements of cooling tower applications. They can be engineered to have various shapes, sizes, and dimensions to fit the specific needs of the cooling tower design. Overall, FRP pultrusion profiles are a reliable and cost-effective choice for cooling tower applications, offering corrosion resistance, high strength-to-weight ratio, thermal insulation, and customization options.

Send your message to us

FRP Pultrusion Profiles - Fiberglass Profile C

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 20000m m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords