FRP Pultrusion Profiles - Lightweight, High Strength FRP Pultruded Grating with Best Quality on Hot Sales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PRODUCT DESCRIPTION

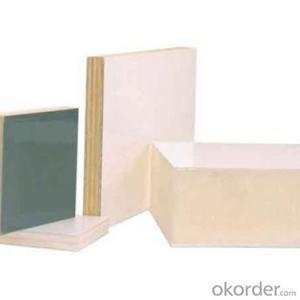

Pultruded grating is made by a particular assembly process, which using “I” shape as its main load-bearing and special rod to go through the bearing bar. Pultruded grating include the standard grating and the custom grating, the custom grating can be designed to meet customer’s requirement or special using condition by changing the shape, size and space of the bearing bars, the surface can be covered with lozenge panel, grit panel, or added the anti-slippery sand directly.

FRP pultruded grating has the most characteristics of molded grating, but it has its distinct advantages, it has very high fiberglass content in the loading direction, so it has very high load capability, it has more superiority when used at wide span, so that the basic support will be decreased and the project cost will be reduced accordingly.

SPECIFICATION

Thickness (mm) | Bar width (mm) | Open space (mm) | Open rate (%) | Approx weight (kg/m |

25.4 | 15.2 | 22.8 | 60 | 13.2 |

25.4 | 15.2 | 15.2 | 50 | 15.9 |

25.4 | 15.2 | 10.1 | 40 | 18.5 |

25.4 | 40 | 10.8 | 21 | 14.5 |

38.1 | 15.2 | 22.8 | 60 | 15.8 |

38.1 | 15.2 | 15.2 | 50 | 19.1 |

38.1 | 15.2 | 10.1 | 40 | 22.4 |

50.8 | 25.4 | 25.4 | 50 | 16.6 |

50.8 | 25.4 | 12.7 | 33 | 21.1 |

FEATURES

a. Anti-corrosion and anti-rust

b. Light weight and high strength

c.Good economic benefit

d. Anti- fatigue

e. Safe and anti-slippery

f. Anti-ageing

g. Easy of maintenance

h. Excellent electromagnetism property

FIELDS SERVED

Sewage treatment,

water supply and drainage,

chemical industry,

oil industry,

power engineering,

pulp and paper,

construction engineering,

spinning, marine engineering.

APPLICATION

Operation terrace,

stair walkway,

ground floor,

trench cover,

sidewalk,

foot bridge,

equipment safety fence,

scaffold.

COMPANT DESCRIPTION

CNBM,China National Building Materials Group is a state-owned enterprise in charge of administrative affairs in china building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of 25 billion RMB and a total staff of 30,000.CNBM now owns 200 subordinating firms of solely owned and joint-venture companies.

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products,professional service and complete solution to our customers. Strong delivery capacity, advanced technology& management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

FAQ

1.Q:Are you factory or trading company ?

A:We are Factory produce FRP machines and FRP products.

2.Q:If can customized by customers requirements?

A:yes,we can produce the machine with customized size.

3.Q:How about the payment?

A:We accept any kind of payment.

4.Q:What is the guarantee?

A:Gurantee is one year.

5.Q:If you can training?

A:yes ,we can training in our factory also can send engineers to your factory training.

PICTURES

- Q: Can FRP pultrusion profiles be used in the construction of outdoor signage?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of outdoor signage. FRP pultrusion profiles are known for their durability, strength, and resistance to various environmental conditions, making them suitable for outdoor applications. These profiles are typically made of a combination of fiberglass reinforcement and resin matrix, resulting in a lightweight yet strong material. Outdoor signage often needs to withstand harsh weather conditions, such as rain, sun exposure, and temperature fluctuations. FRP pultrusion profiles have excellent resistance to corrosion, UV rays, and moisture, ensuring that the signage can maintain its structural integrity and visual appeal over time. Furthermore, FRP pultrusion profiles can be customized to meet specific design requirements, allowing for flexibility in creating unique and eye-catching outdoor signage. These profiles can be easily shaped, cut, and assembled, making them a versatile choice for signage applications. In summary, FRP pultrusion profiles can indeed be used in the construction of outdoor signage due to their durability, resistance to environmental conditions, and flexibility in design.

- Q: Are FRP pultrusion profiles resistant to impact?

- FRP pultrusion profiles exhibit a general resistance to impact. The amalgamation of robust fibers and the polymer matrix employed during manufacturing renders FRP profiles exceptionally enduring, enabling them to endure substantial impacts without fracturing or shattering. Furthermore, the pultrusion process guarantees the uniform dispersion of fibers within the profile, thereby bolstering its capacity to resist impact. Consequently, FRP pultrusion profiles are ideally suited for impact-prone applications, including construction, transportation, and infrastructure ventures.

- Q: Can FRP pultrusion profiles be used in electrical or telecommunications applications?

- FRP pultrusion profiles have a wide range of applications in the electrical and telecommunications industries. These profiles are highly regarded for their exceptional electrical insulating properties, impressive strength-to-weight ratio, and resistance to corrosion. As a result, they are well-suited for various electrical and telecommunications purposes. When it comes to electrical applications, FRP pultrusion profiles can function as electrical insulators, cable trays, busbar supports, and electrical enclosures. They serve to insulate and safeguard against electrical shocks, making them a popular choice for replacing traditional materials like metal or wood. Moreover, their non-conductive properties, along with their lightweight and easy installation, make them highly suitable for electrical applications. In the realm of telecommunications, FRP pultrusion profiles are utilized for cable management systems, antenna supports, and equipment enclosures. Similar to their electrical applications, the non-conductive nature of these profiles ensures the safety and reliability of the telecommunications infrastructure. Additionally, these profiles can be tailored to meet specific design requirements, such as incorporating cable routing channels or equipment mounting brackets. Furthermore, FRP pultrusion profiles exhibit exceptional resistance to harsh environmental conditions, such as moisture, UV radiation, and chemicals. This makes them an excellent choice for outdoor electrical or telecommunications installations, where exposure to these elements is commonplace. All in all, FRP pultrusion profiles have proven themselves to be a dependable and cost-effective option for electrical and telecommunications applications. They provide insulation, strength, durability, and resistance to environmental factors, making them highly sought-after in these industries.

- Q: Are FRP pultrusion profiles resistant to oils and greases?

- Yes, FRP pultrusion profiles are generally resistant to oils and greases. The combination of fiberglass reinforcement and resin matrix in FRP pultrusions provides excellent resistance to various chemicals, including oils and greases. This makes them suitable for applications where exposure to oils and greases is expected.

- Q: Are FRP pultrusion profiles resistant to chemicals used in food packaging?

- FRP pultrusion profiles have proven to be highly resistant to chemicals typically employed in the realm of food packaging. Their remarkable ability to withstand a vast array of chemicals, including acids, bases, solvents, and oils, is well-documented. Consequently, FRP pultrusion profiles are a fitting option for applications that necessitate interaction with food packaging materials. Nevertheless, it is crucial to acknowledge that the chemical resistance of FRP profiles may differ based on the formulation and type of resin utilized. Consequently, it is prudent to seek guidance from the manufacturer or supplier to ensure that the chosen FRP pultrusion profiles are compatible with the specific chemicals employed within the food packaging industry.

- Q: Are FRP pultrusion profiles UV resistant?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally UV resistant. The composite materials used in pultrusion manufacturing typically have inherent resistance to ultraviolet (UV) radiation. Additionally, manufacturers often incorporate UV inhibitors and protective coatings to enhance the UV resistance of the profiles, making them suitable for outdoor applications exposed to sunlight and other environmental conditions.

- Q: Can FRP pultrusion profiles be used in the construction of theme park rides?

- Yes, FRP pultrusion profiles can be used in the construction of theme park rides. FRP (Fiber Reinforced Polymer) pultrusion profiles are known for their high strength-to-weight ratio, corrosion resistance, and durability, making them suitable for various structural applications. These profiles can be used to build ride components such as supports, beams, frames, and safety structures, providing a lightweight yet robust solution for theme park rides.

- Q: Can FRP pultrusion profiles be used in chemical storage tanks?

- Indeed, it is possible to utilize FRP pultrusion profiles in the construction of chemical storage tanks. These profiles are recognized for their exceptional resistance to corrosion, rendering them suitable for the storage of a wide array of chemicals. Moreover, their lightweight nature, strength, and impressive strength-to-weight ratio make them an optimal choice for the creation of robust and long-lasting chemical storage tanks. Furthermore, FRP pultrusion profiles can be tailor-made to fulfill specific design requirements, enabling flexibility in tank design and construction. In summary, due to their corrosion resistance, strength, and customization capabilities, FRP pultrusion profiles emerge as a dependable and cost-efficient alternative for chemical storage tanks.

- Q: What are the limitations of using FRP pultrusion profiles?

- When selecting materials for a particular application, it is crucial to take into account several limitations associated with the use of FRP (Fiber Reinforced Polymer) pultrusion profiles. Firstly, FRP pultrusion profiles have limited design flexibility due to their fixed cross-sectional shape, which is a result of the continuous manufacturing process. This restricts the ability to create complex or custom profiles, making them less flexible in design compared to metals or plastics. Secondly, FRP materials are susceptible to UV degradation. Prolonged exposure to sunlight can cause fading, discoloration, and loss of mechanical properties. To ensure long-term durability in outdoor applications, it is necessary to implement proper surface coatings or UV protection measures. Thirdly, FRP pultrusion profiles generally have lower impact resistance compared to metals. While they offer excellent strength-to-weight ratios, they may be more prone to damage from impacts or heavy loads. Therefore, careful handling and structural reinforcement may be necessary to mitigate the risk of damage. Additionally, FRP materials have a relatively high coefficient of thermal expansion compared to metals. This means that they will expand and contract significantly with changes in temperature. Proper allowances and design calculations must be made to ensure dimensional stability and prevent issues such as buckling or warping. Furthermore, FRP pultrusion profiles are generally combustible and can contribute to the spread of fire. While some FRP materials can be formulated with fire-retardant additives, they may still not meet the stringent fire safety requirements of certain applications. In situations where fire resistance is critical, alternative materials with better fire resistance properties may be preferred. Lastly, it is important to consider cost considerations when choosing FRP pultrusion profiles. They can be more expensive compared to traditional materials like steel or aluminum, especially when specialty reinforcements or additives are involved. However, the overall life cycle cost, including maintenance, durability, and weight savings, should be considered to determine the cost-effectiveness of FRP profiles for a specific application. Therefore, it is crucial to carefully evaluate these limitations and compare them against the specific requirements and constraints of the intended application to determine whether FRP pultrusion profiles are the most suitable materials to use.

- Q: What are the mechanical properties of FRP pultrusion profiles?

- FRP pultrusion profiles have several desirable mechanical properties. They are known for their high strength-to-weight ratio, which makes them lightweight yet strong. Additionally, FRP pultrusion profiles exhibit excellent corrosion resistance, making them suitable for use in harsh environments. They also have good dimensional stability, meaning they do not easily warp or deform over time. Moreover, FRP pultrusion profiles have a high stiffness, providing structural integrity and minimizing deflection under load.

Send your message to us

FRP Pultrusion Profiles - Lightweight, High Strength FRP Pultruded Grating with Best Quality on Hot Sales

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords