FRP Pultrusion Profiles - Anti-Corrosion, Non-Rusty, Toxic-Free FRP Pultruded Grating Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 18 watt

- Supply Capability:

- 30000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

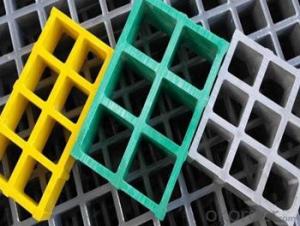

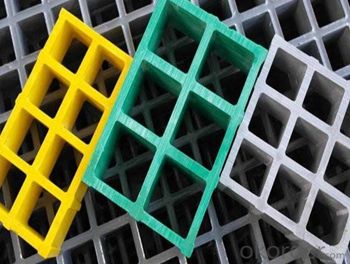

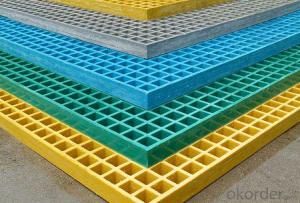

Pultruded grating is made by a particular assembly process, which using “I” shape as its main load-bearing and special rod to go through the bearing bar. Pultruded grating include the standard grating and the custom grating, the custom grating can be designed to meet customer’s requirement or special using condition by changing the shape, size and space of the bearing bars, the surface can be covered with lozenge panel, grit panel, or added the anti-slippery sand directly.

SPECIFICATION

The standard space between two crossbars is 6 inch or 12 inch.

Thickness (mm) | Bar width (mm) | Open space (mm) | Open rate (%) | Approx weight (kg/m |

25.4 | 15.2 | 22.8 | 60 | 13.2 |

25.4 | 15.2 | 15.2 | 50 | 15.9 |

25.4 | 15.2 | 10.1 | 40 | 18.5 |

25.4 | 40 | 10.8 | 21 | 14.5 |

38.1 | 15.2 | 22.8 | 60 | 15.8 |

38.1 | 15.2 | 15.2 | 50 | 19.1 |

38.1 | 15.2 | 10.1 | 40 | 22.4 |

50.8 | 25.4 | 25.4 | 50 | 16.6 |

50.8 | 25.4 | 12.7 | 33 | 21.1 |

FEATURES

a. Anti-corrosion and anti-rust

b. Light weight and high strength

c. Anti-flammable

d. Anti- fatigue

e. Safe and anti-slippery

f. Anti-ageing

g. Easy of maintenance

h. Excellent electromagnetism property

i. Good economic benefit

APPLICATION

Operation terrace,

stair walkway,

ground floor,

trench cover,

sidewalk,

foot bridge,

equipment safety fence,

scaffold.

COMPANT DESCRIPTION

CNBM,China National Building Materials Group is a state-owned enterprise in charge of administrative affairs in china building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of 25 billion RMB and a total staff of 30,000.CNBM now owns 200 subordinating firms of solely owned and joint-venture companies.

FAQ

1.Q:Are you factory or trading company ?

A:We are Factory produce FRP machines and FRP products.

2.Q:If can customized by customers requirements?

A:yes,we can produce the machine with customized size.

3.Q:How about the payment?

A:We accept any kind of payment.

4.Q:What is the guarantee?

A:Gurantee is one year.

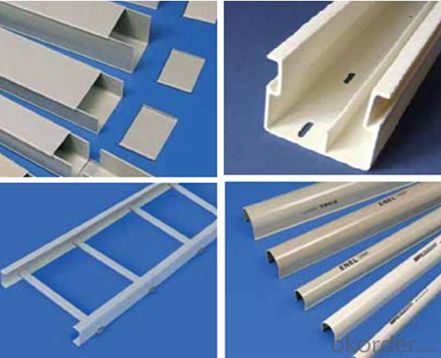

PICTURES

- Q: Are FRP pultrusion profiles resistant to seismic activity?

- FRP (Fiber Reinforced Polymer) pultrusion profiles are known for their high strength-to-weight ratio and excellent mechanical properties. However, when it comes to seismic activity, their resistance depends on various factors. In general, FRP pultrusion profiles can exhibit good resistance to seismic activity due to their inherent properties. The composite materials used in their construction, such as fiberglass and resin, offer high tensile strength and stiffness, making them capable of withstanding dynamic loads caused by earthquakes. Moreover, FRP pultrusion profiles have been extensively tested and proven to possess excellent fatigue resistance. This property is crucial during seismic events as structures are subjected to repeated dynamic loading. The ability of FRP profiles to withstand cyclic loading without suffering from fatigue failure significantly enhances their seismic resistance compared to traditional materials like steel or concrete. Another advantage of FRP pultrusion profiles in seismic activity is their lightweight nature. Their low weight reduces the overall mass of the structure, resulting in lower seismic forces. This weight reduction can lead to reduced seismic responses and less damage during an earthquake. However, it is important to note that the seismic resistance of FRP pultrusion profiles can be influenced by various factors. These include the design and quality of the profiles, the connection details, and the overall structural system in which they are used. Proper engineering and design considerations must be taken into account to ensure optimal performance and seismic resistance. In conclusion, FRP pultrusion profiles have the potential to offer good resistance to seismic activity due to their high strength, stiffness, and fatigue resistance. However, their performance in seismic events depends on various factors, and careful design and engineering practices are essential to maximize their seismic resistance.

- Q: Can FRP pultrusion profiles be used in the mining and mineral processing industry?

- The mining and mineral processing industry can indeed utilize FRP (Fiber Reinforced Polymer) pultrusion profiles. These profiles possess multiple properties that render them suitable for application in this industry. To begin with, FRP pultrusion profiles are characterized by their lightweight yet remarkably strong composition. This quality makes them ideal for situations where weight reduction holds significance, such as in mining equipment or processing plants. Despite their lightweight nature, FRP profiles can endure substantial loads and withstand corrosion. This is particularly advantageous in the mining industry, where equipment is exposed to harsh environments and corrosive substances. Furthermore, FRP pultrusion profiles are non-conductive with exceptional electrical insulation properties. This proves beneficial in mining and mineral processing operations, where electrical safety takes precedence. FRP profiles can be utilized in scenarios where electrical conductivity must be avoided, such as in electrical enclosures or cable trays. Moreover, FRP pultrusion profiles exhibit high chemical resistance, including resistance to acids and alkalis. This renders them suitable for deployment in mineral processing plants, where various corrosive chemicals are employed in mineral extraction and processing. FRP profiles can withstand exposure to these chemicals without deteriorating or sustaining significant damage, consequently increasing their lifespan and reducing maintenance costs. Additionally, FRP pultrusion profiles possess a high strength-to-weight ratio, enabling the construction of durable and lightweight structures. This proves particularly advantageous in mining operations, where structures like walkways, ladders, and platforms need to be installed in challenging terrains. The lightweight nature of FRP profiles facilitates easier transportation, handling, and installation compared to traditional materials like steel. In conclusion, FRP pultrusion profiles offer a viable option for various applications in the mining and mineral processing industry due to their lightweight composition, high strength, corrosion resistance, electrical insulation, and chemical resistance properties. These profiles present numerous advantages over traditional materials, making them a feasible choice for implementation in this industry.

- Q: What are the different types of FRP pultrusion profiles available?

- Some of the different types of FRP pultrusion profiles available include standard shapes such as I-beams, channels, angles, and tubes. Additionally, there are custom profiles that can be designed and manufactured based on specific project requirements.

- Q: Can FRP pultrusion profiles be used in the water and wastewater treatment industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the water and wastewater treatment industry. FRP pultrusion profiles are highly durable, corrosion-resistant, and have excellent mechanical properties, making them suitable for various applications in the water and wastewater treatment industry. One of the main advantages of FRP pultrusion profiles is their resistance to corrosion. Water and wastewater treatment facilities often deal with aggressive chemicals, high humidity, and corrosive environments. Traditional materials like steel or wood may deteriorate and require frequent maintenance or replacement. However, FRP pultrusion profiles are specifically designed to withstand harsh conditions without corrosion, ensuring long-term performance and reducing maintenance costs. Additionally, FRP pultrusion profiles offer excellent strength-to-weight ratio, making them ideal for structural applications in water and wastewater treatment facilities. They can be used as walkways, handrails, grating, ladders, and other structural components. The lightweight nature of FRP profiles allows for easy installation and minimizes the load on the supporting structures. Furthermore, FRP pultrusion profiles are non-conductive, providing an added safety benefit in water and wastewater treatment facilities. This property is particularly important when dealing with electrical equipment or applications near water sources, reducing the risk of electrical hazards. Moreover, FRP pultrusion profiles can be customized to meet specific design requirements, including different shapes, sizes, and colors. This flexibility allows for greater design freedom, ensuring that the profiles can be tailored to fit the specific needs of water and wastewater treatment projects. Overall, the use of FRP pultrusion profiles in the water and wastewater treatment industry offers numerous advantages, including corrosion resistance, high strength, lightweight, non-conductivity, and design flexibility. These qualities make FRP profiles a reliable and cost-effective choice for various applications in this industry.

- Q: Can FRP pultrusion profiles be used in agricultural structures?

- Agricultural structures can indeed utilize FRP pultrusion profiles. FRP pultrusion profiles, also known as Fiber Reinforced Polymer profiles, possess numerous advantages that render them suitable for agricultural purposes. To begin with, the corrosion resistance of FRP profiles is of utmost importance in the agricultural industry, given the exposure of structures to harsh environments and chemicals like fertilizers and pesticides. Unlike conventional materials such as steel or wood, FRP does not rust or decay, ensuring enduring performance in agricultural structures. Furthermore, FRP profiles are lightweight yet durable, facilitating easy handling and installation in agricultural applications. Their high strength-to-weight ratios enable efficient construction, thereby reducing the necessity for heavy machinery during the installation process. Moreover, FRP profiles exhibit exceptional mechanical properties, including high stiffness and impact resistance, which prove advantageous for agricultural structures subjected to heavy loads, vibrations, or machinery impact. In addition, FRP pultrusion profiles can be designed to resist UV radiation, thereby preventing degradation from prolonged exposure to sunlight. This quality makes them suitable for outdoor agricultural structures consistently exposed to the elements. Lastly, FRP profiles are non-conductive, a critical advantage in agricultural environments where electrical safety is paramount. This characteristic eliminates the risk of electrical hazards associated with conductive materials like steel. In summary, FRP pultrusion profiles offer a reliable and efficient solution for a variety of agricultural structures, such as greenhouse frames, livestock enclosures, irrigation systems, and storage facilities. Their corrosion resistance, lightweight nature, high strength, UV resistance, and non-conductivity make them an ideal choice for agricultural applications.

- Q: What is the tensile strength of FRP pultrusion profiles?

- The tensile strength of FRP pultrusion profiles can vary depending on the specific composition and manufacturing process. However, it is generally known that FRP pultrusion profiles have high tensile strength, often exceeding that of traditional materials like steel.

- Q: Are FRP pultrusion profiles fire resistant?

- FRP pultrusion profiles exhibit excellent fire resistance due to the combination of reinforcing fibers and the polymer matrix employed in their production. These profiles are crafted through the pultrusion process, wherein reinforcing fibers like fiberglass or carbon fiber are impregnated with a thermosetting resin. This resin undergoes a curing process, resulting in a robust and durable composite material. One of the primary advantages of FRP pultrusion profiles lies in their inherent fire resistance. The thermosetting resin utilized in their manufacture possesses properties that render it highly impervious to fire. When subjected to flames or elevated temperatures, the resin does not easily burn or melt, thereby impeding the propagation of fire. Moreover, the reinforcing fibers present in FRP profiles contribute significantly to their fire resistance. For example, fiberglass, being an inorganic substance, does not combust. It serves as a heat transfer barrier, aiding in the containment of flames. Additionally, FRP pultrusion profiles can be engineered to meet specific fire safety standards and regulations. By incorporating supplementary fire retardant additives or employing specialized resin systems, the fire resistance of these profiles can be further enhanced. It is crucial to note that although FRP pultrusion profiles do possess fire resistance, their precise fire rating may vary depending on the particular composition and design. Thus, it is imperative to consult manufacturers or suppliers who can furnish comprehensive information regarding the fire resistance properties of their FRP pultrusion profiles.

- Q: Are FRP pultrusion profiles suitable for the manufacturing of antenna masts?

- Yes, FRP pultrusion profiles are suitable for the manufacturing of antenna masts. FRP pultrusion profiles offer several advantages such as high strength-to-weight ratio, corrosion resistance, and excellent electrical insulation properties. These characteristics make them ideal for antenna mast construction, as they can withstand various environmental conditions and provide reliable support for antennas.

- Q: Are FRP pultrusion profiles resistant to moisture absorption?

- FRP pultrusion profiles possess remarkable resistance to moisture absorption, primarily due to the composition of the materials used in their construction. These profiles typically consist of a combination of fiberglass and resin, wherein fiberglass is naturally non-porous and impervious to moisture, while the resin is specifically designed to repel moisture. The moisture resistance of FRP profiles is further enhanced by the pultrusion manufacturing process. This process involves pulling the fiberglass and resin through a heated die, ensuring thorough impregnation of the fibers with resin and creating a dense and solid structure. Consequently, the resulting product exhibits exceptional resistance to water penetration and moisture absorption. Additionally, the moisture resistance of FRP pultrusion profiles can be augmented through the application of protective coatings or surface treatments, such as gel coats or UV-resistant finishes. These coatings provide an extra layer of defense against moisture ingress. The superior moisture resistance of FRP pultrusion profiles makes them an ideal choice for applications that involve exposure to water or high humidity, such as marine environments, wastewater treatment plants, or outdoor structures. By preventing issues like rot, rust, or degradation commonly associated with materials like wood or metal, these profiles offer a reliable and durable solution that can endure moisture exposure without compromising their structural integrity or performance.

- Q: How do FRP pultrusion profiles withstand extreme temperatures?

- FRP pultrusion profiles are able to withstand extreme temperatures due to the inherent properties of the materials used in their construction. The combination of reinforced fibers, such as fiberglass, and a thermosetting resin matrix creates a composite material with high thermal stability. This enables the profiles to maintain their structural integrity and dimensional stability even under extreme heat or cold conditions. Additionally, the design and manufacturing process of FRP pultrusion profiles ensures that the materials are evenly distributed and tightly bonded, further enhancing their ability to withstand temperature variations without compromising their strength.

Send your message to us

FRP Pultrusion Profiles - Anti-Corrosion, Non-Rusty, Toxic-Free FRP Pultruded Grating Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 18 watt

- Supply Capability:

- 30000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords