FRP Pultrusion Profiles - Anti-Corrosion and Anti-Rust Machine Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 55 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

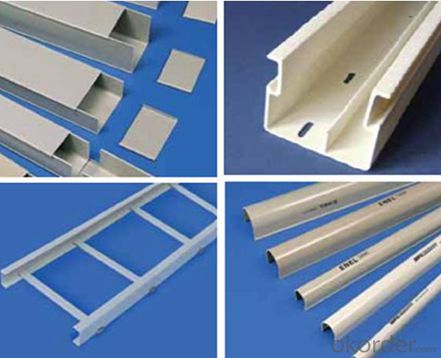

PRODUCT DESCRIPTION

Pultruded grating is made by a par ticular assembly process, which using “I” shape as its main load-bearing and special rod to go through the bearing bar. Pultruded grating include the standard grating and the custom grating, the custom grating can be designed to meet customer’s requirement or special using condition by changing the shape, size and space of the bearing bars, the sur face can be covered with lozenge panel, grit panel, or added the anti-slippery sand directly.

1.SPECIFICATION

The standard space between two crossbars is 6 inch or 12 inch.

Thickness (mm) | Bar width (mm) | Open space (mm) | Open rate (%) | Approx weight (kg/m |

25.4 | 15.2 | 22.8 | 60 | 13.2 |

25.4 | 15.2 | 15.2 | 50 | 15.9 |

25.4 | 15.2 | 10.1 | 40 | 18.5 |

25.4 | 40 | 10.8 | 21 | 14.5 |

38.1 | 15.2 | 22.8 | 60 | 15.8 |

38.1 | 15.2 | 15.2 | 50 | 19.1 |

38.1 | 15.2 | 10.1 | 40 | 22.4 |

50.8 | 25.4 | 25.4 | 50 | 16.6 |

50.8 | 25.4 | 12.7 | 33 | 21.1 |

2.CHOICE FOR PULTRUDED GRATING

Resin: GP resin, ISO resin,VE resin,Phenolic resin

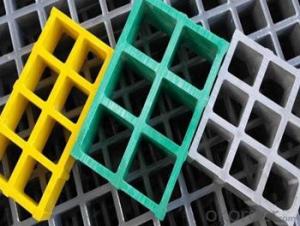

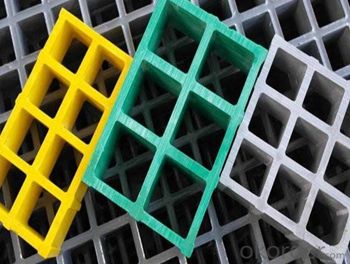

Color choice: Yellow, gray, green, custom color

Surface choice: Groove surface, grit surface, lozenge cover surface

3.FEATURES

a. Anti-corrosion and anti-rust

b. Light weight and high strength

c. Anti-flammable

d. Anti- fatigue

e. Safe and anti-slippery

f. Anti-ageing

g. Easy of maintenance

h. Excellent electromagnetism property

i. Good economic benefit

4.FIELDS SERVED

Sewage treatment,

water supply and drainage,

chemical industry,

oil industry,

power engineering,

pulp and paper,

construction engineering,

spinning, marine engineering.

COMPANT DESCRIPTION

CNBM,China National Building Materials Group is a state-owned enterprise in charge of administrative affairs in china building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of 25 billion RMB and a total staff of 30,000.CNBM now owns 200 subordinating firms of solely owned and joint-venture companies.

CNBM International Corporation is one subsidiary of CNBM, we focus on offering good-quality products,professional service and complete solution to our customers. Strong delivery capacity, advanced technology& management, strong financing capability and excellent after-sale service are our advantages in sharing international market.

PACKAGING & DELIVERY

1.PACKAGING DETAILS:

standard packing or your requirement

2.DELIVERY DETAIL:

Shipped in 30 days after payment

PICTURES

- Q: Can FRP pultrusion profiles be used in the transportation and logistics industry?

- Yes, FRP pultrusion profiles can be used in the transportation and logistics industry. These profiles offer a lightweight and high-strength alternative to traditional materials like steel or aluminum. They are resistant to corrosion, have excellent dimensional stability, and can be customized to meet specific design requirements. FRP pultrusion profiles are commonly used in applications such as truck bodies, trailers, shipping containers, and infrastructure for transportation and logistics purposes.

- Q: Can FRP pultrusion profiles be used in the oil and gas industry?

- Yes, the oil and gas industry can utilize FRP (Fiber Reinforced Polymer) pultrusion profiles. These profiles offer numerous advantages that make them suitable for use in this sector. To begin with, FRP pultrusion profiles exhibit corrosion resistance. They remain unaffected by harsh conditions such as saltwater, chemicals, and extreme temperatures, thereby avoiding rusting, corrosion, or degradation. Consequently, they prove ideal for offshore platforms, pipelines, and other oil and gas facilities where corrosion poses a significant problem. Moreover, FRP pultrusion profiles possess a high strength-to-weight ratio. Despite being lightweight, they possess remarkable strength, enabling efficient installation, transportation, and handling. This aspect is especially advantageous in the oil and gas industry, where reducing weight is crucial for enhancing operational efficiency and decreasing costs. Additionally, FRP pultrusion profiles can be customized to meet specific requirements. They can be manufactured in various shapes, sizes, and configurations, making them adaptable for diverse applications within the oil and gas industry. Whether it be for structural supports, grating, handrails, or other components, FRP pultrusion profiles can be tailored to perfectly suit the distinct needs of each project. Furthermore, FRP pultrusion profiles offer exceptional electrical insulation properties. This attribute holds immense importance in the oil and gas industry, where electrical safety is of utmost priority. By providing insulation and preventing electrical conductivity, FRP profiles reduce the risk of accidents and ensure the safety of both personnel and equipment. In conclusion, FRP pultrusion profiles have demonstrated their reliability, durability, and cost-effectiveness across various applications within the oil and gas industry. Their resistance to corrosion, high strength-to-weight ratio, customization capabilities, and electrical insulation properties make them an appealing choice for this demanding sector.

- Q: Can FRP pultrusion profiles be used in the construction of water treatment plants?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of water treatment plants. FRP pultrusion profiles have several advantages that make them suitable for this application. Firstly, FRP pultrusion profiles are corrosion-resistant. Water treatment plants are exposed to various corrosive elements, such as chemicals and moisture. Traditional materials like steel and concrete can deteriorate over time due to corrosion, leading to maintenance issues and potential structural failures. However, FRP pultrusion profiles are highly resistant to corrosion, ensuring long-term durability and reducing maintenance costs. Secondly, FRP pultrusion profiles are lightweight and have high strength-to-weight ratios. This makes them easy to handle and transport while maintaining structural integrity. Water treatment plants often require structural elements that can withstand heavy loads and support equipment. FRP pultrusion profiles provide the necessary strength without adding excessive weight, making them an ideal choice for such applications. Additionally, FRP pultrusion profiles are non-conductive and have excellent electrical insulation properties. This can be crucial in water treatment plants, where electrical equipment and wiring are present. The non-conductive nature of FRP helps prevent electrical hazards and ensures safe operation. Furthermore, FRP pultrusion profiles can be customized to meet specific design requirements. They can be manufactured in various shapes and sizes, allowing for flexibility in design and construction. This adaptability makes FRP pultrusion profiles suitable for a wide range of applications within water treatment plants, including structural supports, walkways, handrails, and equipment enclosures. In summary, FRP pultrusion profiles are an excellent choice for the construction of water treatment plants due to their corrosion resistance, lightweight yet strong nature, electrical insulation properties, and customization options. They offer long-lasting durability, reduced maintenance costs, and enhanced safety, making them a reliable and efficient solution for this critical infrastructure.

- Q: Are FRP pultrusion profiles resistant to chemicals used in pharmaceutical packaging?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to chemicals used in pharmaceutical packaging. FRP pultrusion profiles are made of a combination of reinforced fibers and a polymer resin matrix, which provides them with excellent chemical resistance properties. The polymer resin used in FRP profiles is typically selected to be compatible with a wide range of chemicals, including those commonly used in pharmaceutical packaging. FRP profiles have been extensively used in various industries, including pharmaceuticals, due to their high chemical resistance. They are capable of withstanding exposure to a wide range of chemicals, such as acids, bases, solvents, and other aggressive substances commonly found in pharmaceutical packaging processes. This resistance helps protect the integrity of the packaging and ensures that there is no contamination or degradation of the pharmaceutical products. Additionally, FRP pultrusion profiles are also resistant to corrosion, which is another advantage in the pharmaceutical industry where aggressive chemicals may be present. This resistance to corrosion further enhances the durability and longevity of the FRP profiles, making them a reliable choice for pharmaceutical packaging applications. However, it is important to note that the specific chemical resistance of FRP pultrusion profiles may vary depending on the type and concentration of the chemicals being used. Therefore, it is recommended to consult the manufacturer or supplier of the FRP profiles to ensure their compatibility with the specific chemicals used in pharmaceutical packaging.

- Q: Are FRP pultrusion profiles resistant to fungal growth?

- FRP pultrusion profiles are generally resistant to fungal growth. The composite materials, like resins and fibers, used in pultrusion possess inherent resistance to biological degradation, including attacks from fungi. The non-porous nature of FRP pultrusion profiles also poses difficulties for fungi to penetrate and grow on the surface. Furthermore, the manufacturing process involves curing the composite materials at high temperatures, which adds to their resistance against fungal growth. However, it is important to acknowledge that no material is entirely impervious to fungal growth in all conditions. Factors such as high humidity, prolonged exposure to moisture, and inadequate maintenance practices can still contribute to fungal growth on FRP pultrusion profiles, albeit to a lesser extent compared to materials like wood or metal. Regular inspection and appropriate cleaning are crucial to sustain the fungal resistance of FRP pultrusion profiles throughout their lifespan.

- Q: What raw materials do FRP pultrusion require?

- Resin: commonly used unsaturated polyester resin, epoxy resin, vinyl ester resin, phenolic resin;

- Q: Are FRP pultrusion profiles resistant to oil or fuel spills?

- Yes, FRP pultrusion profiles have inherent resistance to oil and fuel spills. The combination of the fiberglass reinforcement and the resin matrix used in their construction make them highly resistant to the corrosive effects of oil and fuel, making them a suitable choice for applications where exposure to such spills is expected.

- Q: Can FRP pultrusion profiles be used in the construction and building materials industry?

- FRP pultrusion profiles are indeed applicable in the construction and building materials sector. These profiles are created by pulling continuous fibers through a resin bath and then into a heated die, which aids in curing the resin and shaping the profile. One of the primary advantages of FRP pultrusion profiles lies in their exceptional strength-to-weight ratio. Despite being lightweight, they possess incredible durability and strength, making them an optimal choice for construction purposes where weight reduction is desired. Moreover, FRP pultrusion profiles exhibit outstanding resistance to corrosion, which proves particularly advantageous in environments with moisture, chemicals, or harsh weather conditions. This corrosion resistance extends the lifespan of building materials, thereby reducing maintenance and replacement expenses. FRP pultrusion profiles can serve a wide array of construction applications, including structural components like beams, columns, and trusses. They are also frequently utilized as reinforcements in concrete structures, offering added strength and durability. Additionally, these profiles find utility in cladding, decking, handrails, ladders, and other non-structural elements within buildings. Furthermore, FRP pultrusion profiles provide design flexibility as they can easily be customized and manufactured to specific shapes, sizes, and properties. This adaptability renders them suitable for diverse construction projects, ranging from small-scale residential buildings to large-scale industrial complexes. In conclusion, FRP pultrusion profiles are highly appropriate for the construction and building materials industry due to their superior strength-to-weight ratio, corrosion resistance, design flexibility, and versatility.

- Q: Can FRP pultrusion profiles be used in the construction of water slides?

- Yes, FRP pultrusion profiles can be used in the construction of water slides. FRP stands for Fiber Reinforced Polymer, which is a composite material that offers several advantages for water slide construction. Firstly, FRP pultrusion profiles are lightweight yet incredibly strong, making them ideal for creating the structural components of water slides. These profiles have high strength-to-weight ratios, meaning they can withstand the dynamic loads and forces experienced in water slide applications without adding excessive weight to the structure. Secondly, FRP pultrusion profiles are highly resistant to corrosion, which is essential for water slide construction. Water slides are constantly exposed to water, chemicals, and harsh weather conditions, which can cause traditional materials like steel to corrode and degrade over time. FRP profiles, on the other hand, are inherently corrosion-resistant, ensuring the longevity and durability of the water slide. Additionally, FRP pultrusion profiles offer design flexibility. They can be customized to various shapes and sizes, allowing for the creation of unique and exciting water slide designs. These profiles can also be easily molded, allowing for the incorporation of various features such as slides, curves, and drops to enhance the overall water slide experience. Lastly, FRP pultrusion profiles have excellent thermal insulation properties. This is beneficial for water slides as it helps maintain the temperature of the water, preventing excessive heat loss or gain. This feature enhances the comfort and enjoyment of users while reducing energy consumption for heating or cooling the water. In conclusion, FRP pultrusion profiles are well-suited for water slide construction due to their lightweight, high strength, corrosion resistance, design flexibility, and thermal insulation properties.

- Q: Are FRP pultrusion profiles resistant to impact from flying debris?

- FRP (Fiber Reinforced Polymer) pultrusion profiles are known for their high strength and durability. They are generally resistant to impact from flying debris due to their inherent properties. The combination of the reinforcing fibers, typically made of fiberglass, and the polymer matrix provides excellent impact resistance. The specific resistance to impact from flying debris can vary depending on the specific design, thickness, and composition of the FRP pultrusion profiles. However, in most cases, these profiles are designed to withstand impact forces and can effectively resist damage caused by flying debris. Furthermore, FRP pultrusion profiles are often used in applications where impact resistance is crucial, such as in construction, transportation, and infrastructure industries. These profiles have been tested and proven to withstand various impact scenarios, making them a reliable choice for applications where flying debris is a concern. It is important to note that while FRP pultrusion profiles offer good impact resistance, the severity of the impact and the velocity of the flying debris can still affect the level of damage. Therefore, it is advisable to consult with the manufacturer or engineer to ensure the specific FRP profile chosen is suitable for the intended application and potential impact conditions.

Send your message to us

FRP Pultrusion Profiles - Anti-Corrosion and Anti-Rust Machine Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 55 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords