Wilsonart Food Grade Aluminum Sheet Pop Up Foil Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

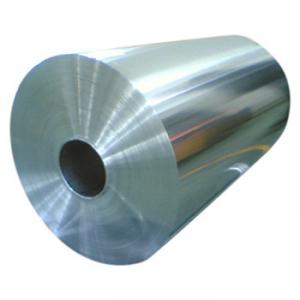

1.Structure of Food Grade Aluminum Sheet Pop Up Foil Sheets Description:

Aluminium foil is an absolute barrier to light, oxygen, gases, moisture, bacteries and provides high level of protection, preservation, conservation of products characteristics for long period of time and without refrigeration.Thanks to its barrier properties, its light weight and its infinite recycling possibilities, aluminium foil in food and beverage applications saves more resources than what it needs for its production. Thanks to effective protection and appropriate format, Aluminum Foil packaging helps to prevent spoilage and waste of valuable food, the production of which requires significantly more resources than the production of its packaging

2.Main Features of Food Grade Aluminum Sheet Pop Up Foil Sheets :

Good Corrosion Resistance

Good Machinability

High Quality

Competitive Price

3. Food Grade Aluminum Sheet Pop Up Foil Sheets Images:

4. Food Grade Aluminum Sheet Pop Up Foil Sheets Specification:

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| A1050,A1060, A1070,A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

| 3A21,A3003,A3105,A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

| A5052 ,A5005,A5083,A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

| A6061,A6082,A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

| A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: Can aluminum sheets be bent or formed without cracking or breaking?

- Yes, aluminum sheets can be bent or formed without cracking or breaking, but it depends on the thickness of the sheet and the method used for bending or forming. Aluminum is a highly malleable metal, which means it can be easily bent or formed into various shapes without breaking. However, if the sheet is too thin or the bending or forming process is done without proper care or precision, there is a risk of cracking or breaking. To avoid this, it is important to use appropriate tools and techniques, such as using a bending brake or a rolling machine, and ensuring that the sheet is not subjected to excessive force or stress during the process. Additionally, annealing the aluminum sheet before bending or forming can increase its flexibility and reduce the chance of cracking. Overall, with the right approach and precautions, aluminum sheets can be successfully bent or formed without cracking or breaking.

- Q: are there any hazards in aluminium?

- Some. The chemical aluminum can get into your blood accumulate. Years ago, there was a study of weather blood aluminum was the cause of Alzheimer disease. Was proven not to be. But that study helped to reduce the amount of aluminum in deodorant sticks.

- Q: Could you tell me the difference between the 6063 aluminum plate and the 5052 aluminum plate?

- 6063 and 5052 alike: aluminum alloys with Mg Mg as the main alloying element

- Q: What is the electrical conductivity of aluminum sheets?

- Aluminum sheets possess a rather high electrical conductivity, positioning aluminum as an exceptional conductor of electricity among typical metals. With an approximate conductivity rating of 37.7 x 10^6 siemens per meter (S/m), aluminum thrives as a favored selection for an array of electrical purposes, including wiring, power transmission lines, and electrical connectors.

- Q: If something is wrong, what kind of glue can be used for bonding the stainless steel sheet and aluminum sheet? The area may be very big. What are some common or good glue to buy?

- Stainless steel plate and aluminum plate usually use acrylic structure glue.Acrylic structural adhesive two-component acrylate modified by synthesis and curing agent structural adhesive composition, A, B two agents are 100% solid components; fast curing, high strength, about 5 minutes to 30 minutes after the initial fixation strength up to 80%, 24 hours after the maximum strength; excellent resistance to acid and alkali, water, oil medium, high temperature resistance, better aging properties of metal items between strong adhesion, resistance strength is better than that of epoxy resin, excellent resistance to thermal shock, working at -30~150 DEG C; compliance with international environmental standards, has passed the European ROSH standard.

- Q: This question asks for the typical dimensions of aluminum sheets utilized in the construction industry.

- <p>The standard size for aluminum sheets used in construction can vary depending on the region and specific application. However, commonly used sizes include 4x8 feet, 4x10 feet, and 5x10 feet. These sheets are typically 0.020 to 0.060 inches thick. It's important to note that custom sizes are also available to meet specific project requirements. Always check with local suppliers or industry standards for the most accurate sizing information.</p>

- Q: Can aluminum sheet be welded?

- Yes, aluminum sheet can be welded.

- Q: Is it possible to use aluminum sheets as a material for flooring?

- <p>Yes, aluminum sheets can be used for flooring materials. They are known for their durability, resistance to corrosion, and ease of maintenance. Aluminum floors are often used in commercial and industrial settings due to their strength and ability to withstand heavy loads. They are also favored for their slip resistance and non-flammable properties, making them a safe choice for various applications. However, they may not be as common in residential settings due to cost and the鍐板喎 feel underfoot compared to traditional flooring materials like wood or carpet.</p>

- Q: What are the different types of surface coatings for aluminum sheets?

- There are several types of surface coatings available for aluminum sheets, including anodizing, powder coating, painting, and laminating.

- Q: I am following a recipe for braised ribs that calls for wrapping the ribs in heavy duty aluminum foil. I don't have heavy duty, so can regular aluminum foil be used as a replacement?

- I'd at least double it, if not triple it in thickness for cooking ribs. Single ply regular aluminum foil won't give you the result you're looking for.

Send your message to us

Wilsonart Food Grade Aluminum Sheet Pop Up Foil Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords