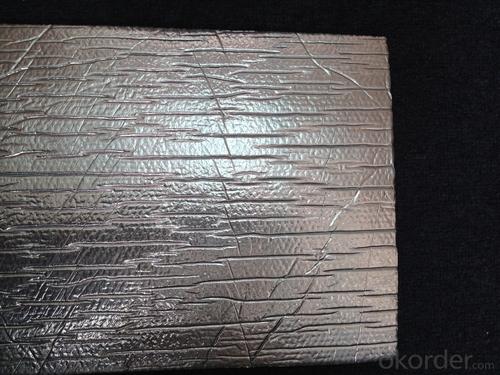

Flexible Ducts Bubble Glasswool with Fiberglass Facing

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application:

1,Building Thermal Insulation Material

(1),Roof,Underlay,Under Concrete & floor Insulation;

(2),Attic,Crawl Space,Stud Wall ,Metal Frame Building Insulation.

2,Wrapping

(1),Protective coatings of ventilating pipe,HVAC Duct & Pipe;

(2),Shells of air conditioner and water heater.

Feature:

1), Waterproof, heavy duty, clean, light, flexible, non-absorbent surface

2), Fire resistant & antiglare

3), Recyclable, environmentally friendly

4), Effective in extreme temperatures both hot and cold

5), Easily install, cut, stapled, nailed or glued into place

6), Safe to handle with no special clothing or breathing Equipment

Feature:

1), Waterproof, heavy duty, clean, light, flexible, non-absorbent surface

2), Fire resistant & antiglare

3), Recyclable, environmentally friendly

4), Effective in extreme temperatures both hot and cold

5), Easily install, cut, stapled, nailed or glued into place

6), Safe to handle with no special clothing or breathing Equipment

- Q: Is it possible to recycle and reuse black fiberglass tissue to create new products?

- <p>Yes, black fiberglass tissue can be recycled and reprocessed into new products. The recycling process involves shredding the material, which can then be used as a filler or reinforcement in various composite materials. However, the recycling of black fiberglass is not as common as that of other colors due to the dye used, which can complicate the recycling process. Despite this, advancements in recycling technology are making it increasingly feasible to recycle black fiberglass and incorporate it into new products, contributing to a more sustainable use of materials.</p>

- Q: Is it possible to utilize black fiberglass tissue as an insulating material?

- <p>Yes, black fiberglass tissue can be used for insulation materials. It is a type of glass wool that provides thermal insulation, sound absorption, and fire resistance. The black color is typically due to the addition of colorants, which do not affect its insulating properties. However, it is important to note that fiberglass insulation, including black fiberglass tissue, should be handled with care due to potential health risks from inhaling fibers and should be installed in accordance with safety guidelines.</p>

- Q: Is it possible to utilize glass fiber paper as a material for sound absorption within room environments?

- <p>Yes, glass fiber paper can be used for acoustic absorption materials in rooms. It is known for its sound-dampening properties due to its porous structure, which allows it to absorb sound waves effectively. However, it's important to note that while it is effective, glass fiber paper may not be the best choice for all applications due to potential health concerns related to the inhalation of fibers. It is often used in professional settings where proper safety measures can be taken, and it is recommended to use it in conjunction with a protective facing or within enclosed systems to minimize exposure.</p>

- Q: This question asks for guidance on the proper cleaning and maintenance methods for black fiberglass tissue to ensure its longevity and appearance.

- <p>To clean and maintain black fiberglass tissue properly, follow these steps: 1. Use a soft brush or cloth to gently remove dust and dirt. 2. For stains, mix a mild detergent with warm water and use a soft sponge to clean the surface. 3. Rinse thoroughly with clean water to remove any soap residue. 4. Dry the area completely with a soft cloth to prevent water spots. 5. Avoid using harsh chemicals or abrasive materials that can damage the fiberglass. 6. Regularly inspect the tissue for any signs of wear or damage and address them promptly. 7. Apply a UV-resistant coating if recommended by the manufacturer to protect against sun damage. Proper care will help maintain the appearance and longevity of your black fiberglass tissue.</p>

- Q: Is it possible to utilize black fiberglass tissue in the creation of garments?

- <p>While it is technically possible to use black fiberglass tissue for clothing, it is not a common practice due to its rigidity and lack of flexibility. Fiberglass is typically used in construction and insulation applications. For clothing, materials that are soft, breathable, and flexible are preferred. If you're looking for a durable fabric, consider alternatives like Kevlar or other synthetic fibers designed for clothing.</p>

- Q: This question asks for methods to clean black fiberglass tissue effectively.

- <p>To clean black fiberglass tissue, start by using a soft brush to remove any loose dirt or debris. Next, mix a mild detergent with warm water and gently scrub the surface with a soft cloth or sponge. Avoid using harsh chemicals or abrasive materials that could damage the fiberglass. After cleaning, rinse thoroughly with clean water and let it dry naturally. For stubborn stains, consider using a fiberglass-specific cleaner, but always test on a small, inconspicuous area first to ensure it doesn't discolor or damage the material. Regular maintenance will help keep your black fiberglass tissue looking its best.</p>

- Q: Is it possible to utilize black fiberglass tape for fixing a leaking faucet or pipe?

- <p>While black fiberglass tape can be used to repair minor leaks in pipes, it is not typically recommended for fixing leaky faucets. For pipes, especially plastic ones, fiberglass tape can create a temporary seal. However, for faucets, plumber's tape (Teflon tape) is more suitable as it is designed to handle the threads and tight seals required in faucet connections. Always remember that for long-term solutions or significant leaks, professional repair or replacement is advisable.</p>

- Q: What are the methods to keep black fiberglass tissue clean and free from dirt?

- <p>To prevent black fiberglass tissue from becoming dirty, follow these steps: 1. Regularly clean the surface with a soft brush or cloth to remove dust and debris. 2. Avoid direct exposure to harsh chemicals or substances that can stain or damage the fiberglass. 3. Use a protective cover or shield when working in areas where dirt or debris is likely to accumulate. 4. Apply a protective coating or sealant specifically designed for fiberglass to create a barrier against dirt and stains. 5. Regularly inspect the fiberglass for any signs of damage or wear, and address these issues promptly to prevent further dirt accumulation.</p>

- Q: This question asks if there are any differences between various brands of black fiberglass tissue.

- <p>Yes, there can be differences between different brands of black fiberglass tissue. These differences may include the quality of the fibers, the thickness and uniformity of the tissue, the level of impurities, and the overall durability. Some brands may use higher quality raw materials or have more stringent manufacturing processes, resulting in a superior product. Additionally, the performance of the black fiberglass tissue can vary based on the specific application, such as in insulation, reinforcement, or acoustical purposes. It's important to consider the specific requirements of your project and choose a brand that meets those needs.</p>

- Q: Is it permissible to use black fiberglass tissue in the construction or components of food processing equipment?

- <p>Black fiberglass tissue is not typically used in food processing equipment due to concerns about food safety and contamination. Fiberglass can potentially shed particles that could contaminate food products. Instead, food processing equipment usually employs materials that are food-grade and non-reactive, such as stainless steel, which is both durable and safe for contact with food. It's crucial to use materials approved for food contact to ensure the safety and quality of the food products.</p>

Send your message to us

Flexible Ducts Bubble Glasswool with Fiberglass Facing

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords