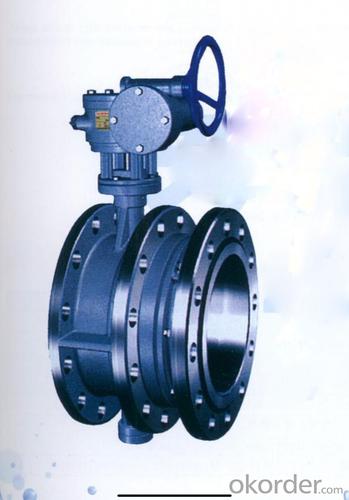

Flexible Butterfly Valve ; Butterfly Valve

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

The flexible butterfly valve is applicable to foodstuff, pharmacy, chemical industry, Prtroleum, electrical industry, textile, paper making, drain and air pipelines to control and stop the flow, with the function of compensating expansion and condensation inder the condition of temperature less than 80°C, nomral pressure less than 1.6MPa.

Main features:

Novel and resanalble design, unique structure, lightweight, convenient operation, quick open/close.

Flexible butterflyy valve is convenient to install, change and repair the valve, basides of adjusting and stop funtion and expansion and condensation funtion since temperature difference from compensation pipelines.

It is adjusttable and changeable for seal parts an reliable sealing function.

Applicable Standard

Design standard: GB/T12238-1989 ; CT/T-261-2007

Flanfe dimension: GB/T9113.1-2000 ;GB/T9113.2-2000 ; GB/T9115.1-2000 ; GB/T9115.2-2000

Pressure test: GB/T13927-1992 ; JB/T9092-1999

Main Techincal Parameter

Nominal Diameter | DN(mm) | 50~2000 | ||||

Nominal Pressure | PN(MPa) | 0.6 | 1.0 | 1.6 | ||

| Intensity Test | 0.9 | 1.5 | 2.4 | |||

| Seal test | 0.66 | 1.1 | 1.76 | |||

| Air Test | 0.6 | 0.6 | 0.6 | |||

Applicable Temperature | <80oC | |||||

| Method | Maual / gear / pneumatic | |||||

Applicable Medium | Air / Water / Steam / Oil Product / Coal gas, etc | |||||

Material for main parts

| Parts Name | Material |

| Body | Castiron / cast steel / Stainless steel / Cr-Mo steel / Alloy steel |

| Disc | Cast steel / Alloy steel / Stainless steel / Cr-Mo steel |

| Seats | Stainless steel / polyactone / PTFE |

| Stem | 2Cr13 / Stainless steel / Cr-Mo steel |

| Bearing | Cast iron / Cast steel / stainless steel / Cr-Mo steel |

| Packing | Flexible graphite |

Please consult customer service before placing an order( in order to confirm with size and material of the relevant product).

- Q: does it come in when you go over a certain rpm or do the valves change depending on how far you depress the throtle?

- The variable is the valve timing. The spark plug fires a split second before the piston reaches the top of the stroke, to give the fuel a bit of time to burn. But, the faster the piston travels in the bore, that split second gets shorter shorter. So the engine computer changes when the spark plug fires when the valves close, to maximize the power from each ignition stroke.

- Q: I got my timing belt done on a 1999 Civic Si on September 26 @ 113,699 miles. at 116,9xx miles I bent a valve on my third cylinder. How likely is it that the timing belt is the reason why this happened? I heard that if the timing belt is a tooth or so off, it could bend a valve. So is it likely that this could have happened? Anyway to check?

- If it was a timing belt issue it woudn't have only been one cylinder. And usually if it's only off by one tooth, it just runs poorly. IT has to be off by quite a bit, or the belt has to straight up break to bend a valve,, if that happened it would have made a horrible clanging noise repeatedly before it eventually sputtered out. the 1999 Si revs to what... 8000 rpms? You didn't happen to miss a shift and over-rev the engine, did you?

- Q: When will Butterfly Valves be used?

- 3, there are anti-corrosion requirements of the pipeline, such as sewage, chemicals, etc.;4 、 pipes that regulate flow control requirements, such as quantitative systems;5, there are open and close, fast opening and closing requirements of the protection of the pipeline system, rapid cutting......

- Q: How do you explain A in butterfly valve D37A1?

- Represents a seal or lining material symbol.Said sealing ring or lining material with the Chinese phonetic alphabet: B Babbitts D nitrided steel, acid resistant stainless steel H, J L Aluminum Alloy, hard rubber, nylon NL, P leather, SA PTFE, SC PVC, SD bakelite, T copper, TC enamel, X rubber, Y hard alloy

- Q: What is the meaning of the D341*5-10 / 16ZB1 turbine butterfly valve flange said?

- D: for clamp, 3: turbine head 4: flange connection 1: vertical plate X5: Ding fine rubber 10/16: nominal pressure Z: gray cast iron valve body, B1: valve plate material is ductile iron

- Q: Butterfly valve D71X-10 and butterfly D371X-10 what is the difference?

- One more 3 in D71X-10 stands for adding a worm gear to the valve. What are the same, the difference is driven by the handle into the drive, gear drive, worm gear drive for large caliber butterfly valve a little less, because the valve torque is big, big, hard to handle and can rotate, and if the worm, you can turn a few laps handwheel. If there are other questions, we can continue to ask questions, the city butterfly valve manufacturers

- Q: D what's the meaning of "one 71x one 1 butterfly"?

- According to the provisions of the JB/T 308-2004 valve type programming method:D== butterfly valve7== clip typeLinetype in 1==X== sealing surface material: Rubber-1== pressure rating: 1.0MPa

- Q: Which is more expensive, gate valve or butterfly valve?

- Gate valve.Under normal circumstances, if you need to adjust the good point, to use the gate valve, and if better, you can choose the cut-off valve.But the price is also butterfly valve, gate valve, globe valve increasing.

- Q: What are the uses and classifications of manually operated clip butterfly valves?

- Classification: butterfly valves are commonly used on the clip butterfly valve and flange butterfly valve two. The clip type butterfly valve is connected with the two pipe flange with a stud bolt. The flange type butterfly valve is provided with a flange on the valve, and bolts are used to connect the flanges at the ends of the valve to the pipe flange.

- Q: What's the meaning of butterfly valve d371po?

- According to the provisions of the JB/T 308-2004 valve type programming method:D== butterfly valve3== transmission: worm gear7== connection mode: clip type1== structure: midlinePo== sealing surface material: lining PoPo== propylene oxide (PO)

Send your message to us

Flexible Butterfly Valve ; Butterfly Valve

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 30000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords