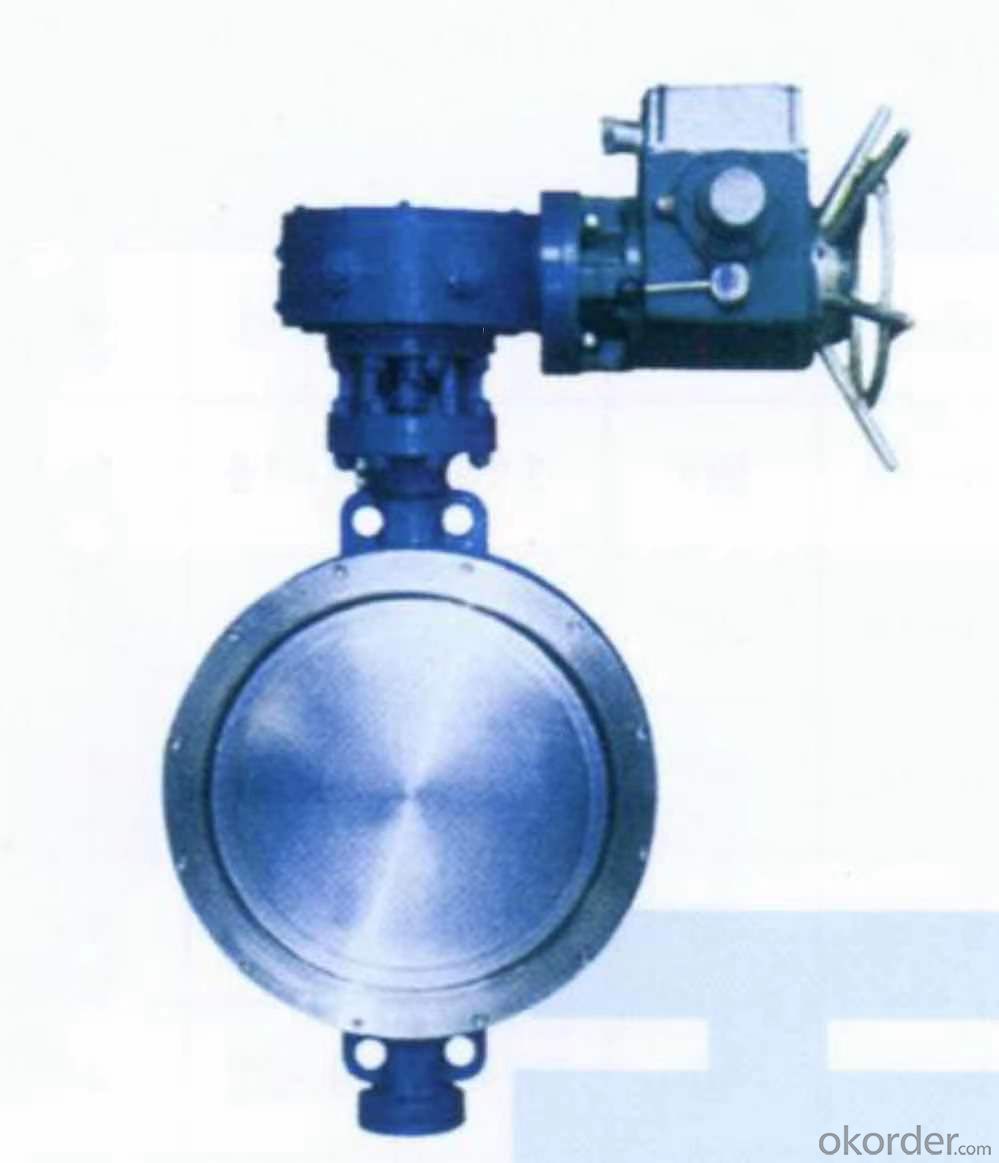

Elastic Meta-to-metal Butterfly Valve ; Butterfly Valve

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Usage and Features:

The metal-to-metal butterfly valve realize veritable zero leakage bu installing and elastic seal ring of stainless steel on the body:

Adjustable seal, lifetime of 100,000 times without leakage

Special seal structure: Seal won't be deformed with the force, with no leakage under high temperature and cold condition

Three-eccentric structure, separated if open and sealed if closed

It solves the wearing problem of seal faces to avoid seay leakage by axial positioner, and the actuator can be installed at any direction

It is applicable to the cleaning pipelines of foodstuff, pharmacy, petrochemical industrial, Industrial Environment protection, Water Solution, high building and water treatment, supplying and drain pipelines as open/closed function or adjust the flow.

Applicable Standard

Design standard: GB/T12238-1989 ; CJ/T261-2007

Flange dimension: GB/T9113.1-2000 ; GB/T9113.2-2000 ; GB/T9115.1-2000 ; GB/T9115.2-2000

Face-to-face: GB/T12221-1989

Pressure test: GB/T13927-1992 ; JB/T9092-1999

Main Techincal Parameter

Nominal Diameter | DN(mm) | 50~150 | ||||

Nominal Pressure | PN(MPa) | 1.0 | 1.6 | 2.5 | ||

| Intensity Test | 1.5 | 2.4 | 3.75 | |||

| Seal test | 1.1 | 1.76 | 2.75 | |||

| Air Test | 0.6 | 0.6 | 0.6 | |||

Applicable Temperature | -40oC ~ 600oC | |||||

Applicable Medium | Water / Steam / Oil Product / corrosive acid, etc | |||||

Material for main parts

| Parts Name | Material |

| Body | Castiron / cast steel / Stainless steel / Cr-Mo steel / Alloy steel |

| Disc | Cast steel / Alloy steel / Stainless steel / Cr-Mo steel |

| Seat ring | Stainless steel / polyactone / anti-wearing material |

| Stem | 2Cr13 / Stainless steel / Cr-Mo steel |

| Packing | Flexible graphite |

Please consult customer service before placing an order( in order to confirm with size and material of the relevant product).

- Q: I want to switch off the water in the bathroom only due to replacing sink taps, will water still come out of the pipe if i turn the stop valve

- Only water what is still in the pipes will come out but you will lose all your hot water in the hot water cistern if you have that type of hot water storage tank.

- Q: Butterfly valve model D344H and D343 difference

- [2]: butterfly valve also known as butterfly valve, control valve has a simple structure, can be used for low pressure pipeline valve switching control is closed parts (disc or disc) is a disk, around the valve axis to achieve the opening and closing a valve, the valve can be used to control the air water, steam, and all kinds of corrosive media, mud, oil, metals and radioactive liquid media and other types of fluid flow. On the pipeline, mainly from cutting and throttling. Butterfly valve headstock is a disc shaped disc, in the valve body around its own axis of rotation, so as to achieve the purpose of opening or closing or regulation.The answer is recommended by Gu Fengxiang, a member of the science education category

- Q: How can one - way sealed butterfly valves and two-way sealed butterfly valves be distinguished?

- The difference between one way butterfly valve and two way butterfly valve:One way hard sealing butterfly valve:The butterfly's body usually has an arrow to indicate the direction of media flow, the butterfly valve plate in front of the closed, must face the flow of media, so we should pay attention to the medium flow direction when installing a one-way valve.

- Q: Gate valve and butterfly valve which is installed when there is a direction?

- There is no direction when installing the valve. The butterfly valve has an eccentric butterfly valve which is in the direction of installation

- Q: What does butterfly valve do?

- 5, connections are flanged, wafer connections, welded connections and lugs on the clip connection. ?Drive in the form of manual, worm gear, electric, pneumatic, hydraulic, electro-hydraulic linkage actuator, can realize remote control and automation.Advantages of butterfly valves1, opening and closing convenient, fast and labor-saving, fluid resistance is small, you can often operate. ?2, simple structure, small volume, light weight. ?3, to transport slurry, accumulation of fluid in the pipe outlet at least. ?4, under low pressure, can achieve a good seal. ?5, good regulating performance.Disadvantages of butterfly valve1, use pressure and working temperature range is small. ?2, poor sealing. ?Butterfly structure can be divided according to the bias plate, vertical plate, inclined plate and lever type. According to the form of sealing can be divided into soft sealing type and hard sealing type of two. The soft sealing type usually adopts rubber ring seal, and the hard sealing type usually adopts metal ring seal. ?By connection type can be divided into flange and clamp connections; press can be divided into manual transmission, gear transmission, pneumatic, hydraulic and electric types.

- Q: My bike has now 6200 miles on the odometer. The manual says that a valve adjustment should be performed every 6000 miles. But the bike runs fine. Can I just have the valve checked or should I have them adjusted even though the bike is fine? What will happen if I just keep riding it?

- if the valves are not chattering (WOrse then normal) and you havent lost power or gas milage, then no...dont get it adjusted and no ... your not hurting the bike.

- Q: Butterfly valve D71X-1.6C, DN50, there is no difference between C and no C? What do you mean by "concrete"?

- D stands for butterfly valve. 71 represents the clamp type, X represents the sealing surface material, and 16 represents the valve to bear the pressure 1.6MPA, C position is the valve body material code, omitted to represent gray cast iron valve; C represents the valve body material is carbon steel.

- Q: What is the D37-10Q butterfly valve?

- D- butterfly valve (valve type); 3- worm (drive); 7- pairs of clamp (connection); 10-PN1; nominal pressure of 10 kg; Q- ductile iron (valve body material).

- Q: What is the difference between the installation and function of a butterfly valve and butterfly valve?

- Therefore, the fully open position of the valve is determined by the position of the gate. Some gate valve, stem nut is located on the gate, the handwheel rotates to drive the stem to rotate, and make the gate lift, this kind of valve is called rotary bar gate valve, or call dark rod gate valve. The type of gate width, sealing surface configuration can be divided into wedge gate valve and parallel gate valve, wedge gate type valve can be divided into: single gate type, dual gate plate and the flexible gate type; parallel gate type valve can be divided into single and dual gate gate plate. According to the thread position of the valve stem, can be divided into two kinds of open rod gate valve and dark rod gate valve. Valve installation and maintenance should pay attention to the following: hand wheel, handle and transmission mechanism are not allowed for lifting, and is strictly prohibited. Double gate valve should be installed vertically, that is, the valve stem is in a vertical position, and the handwheel is at the top. The gate valve with bypass valve shall be opened before opening to balance the pressure difference between inlet and outlet and reduce the opening force. The gate valve with drive mechanism is installed according to the instruction of the product instruction. If the valve is constantly switched on, lubricate it at least once a month. The valve has the advantages of small fluid resistance, the sealing surface by the erosion of small and medium Chong brush. Opening and closing is more labor-saving. Medium flow direction is unrestricted, no disturbance, no pressure reduction. The utility model has the advantages of simple shape, short structural length, good manufacturing technique and wide application range. Valve faults between the sealing surface can lead to erosion and abrasion, maintenance more difficult. Larger size, open need a certain space, long opening and closing time. Complex structure.

- Q: What is the difference between wafer (flangeless) type and LUG type of butterfly valves?

- WAFER butterfly valve is the valve is divided into LUG (ears) with and without LUG, ordinary LUG without clip on 12 points in the direction of valve is generally two to four bolt holes was not, whereas the LUG of butterfly valve cross dispersed in a circle. Bolt hole. With LUG all bolted through the LUG, so that the butterfly valve and the clamp on the two flange connection is more solid, you check the valve picture, it is easy to understand

Send your message to us

Elastic Meta-to-metal Butterfly Valve ; Butterfly Valve

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords