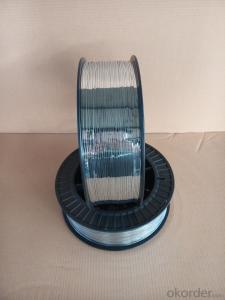

FLAT STEEL WIRE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

1、 SIZE :

2.50mm×0.50mm 2.50mm×0.60mm 2.50mm×0.70mm And the special requirements of other specifications.

2、 TENSILE STRENGTH :

750-1000 N/mm2 And other special requirements.

3、WIRE DIAMETER TOLERANCE :

±0.02mm

4、 PACKING :

TYP | Flange size | Coil size | Height | Hole size | Net weight |

25lbs axis | 225mm | 60mm | 67mm | 11kg | |

2.5kg roll | 130mm | 50mm | 74mm | 2.5kg | |

BP3 axis | 140mm | 57mm | 18mm | 3kg |

- Q: What are the applications of steel in the chemical industry?

- Steel has numerous applications in the chemical industry due to its exceptional properties. It is commonly used for constructing chemical storage tanks, pipelines, and equipment due to its high strength, durability, and resistance to corrosion. Steel is also utilized in the production of catalysts, reactors, and heat exchangers, where it can withstand high temperatures and pressure. Additionally, steel is an essential material for constructing industrial buildings, support structures, and platforms that house chemical manufacturing facilities.

- Q: How is steel used in the production of construction machinery and equipment?

- Steel is extensively used in the production of construction machinery and equipment due to its high strength, durability, and flexibility. It is used to manufacture the structural framework, frames, and chassis of machinery, providing stability and support. Steel is also employed in the fabrication of essential components like gears, axles, and hydraulic systems, ensuring efficient performance and longevity. Additionally, steel's resistance to corrosion and extreme temperatures makes it ideal for construction equipment that operates in harsh environments. Overall, steel plays a crucial role in enhancing the reliability and overall performance of construction machinery and equipment.

- Q: What are the applications of steel wire mesh in marine environments?

- Steel wire mesh is commonly used in marine environments for various applications. One of the main applications is in the construction of offshore structures, such as oil rigs and platforms, where steel wire mesh is used for reinforcement and to provide structural stability. Additionally, steel wire mesh is used as a protective barrier against corrosion and erosion in coastal areas, preventing soil erosion and protecting shorelines. It is also used in aquaculture to create cages and nets for fish farming, as well as in marine equipment and machinery for filtration, separation, and containment purposes. Overall, steel wire mesh is an essential material in marine environments due to its strength, durability, and resistance to corrosion.

- Q: How do steel products contribute to the construction of theme-based botanical gardens?

- Steel products contribute to the construction of theme-based botanical gardens in several ways. Firstly, steel is a durable and reliable material that can withstand various weather conditions, making it ideal for structures like greenhouses, arboretums, and walkways in the gardens. Additionally, steel can be easily molded and fabricated into different shapes, allowing for the creation of intricate and unique designs that align with the theme of the garden. Steel products such as fences, gates, and decorative elements also enhance the aesthetics and security of the botanical gardens, creating a visually appealing and safe environment for visitors to enjoy.

- Q: How is steel used in the production of packaging materials?

- Steel is commonly used in the production of packaging materials due to its strength, durability, and recyclability. It is used to create cans, containers, and lids that can safely hold and preserve various products, such as food, beverages, and chemicals. Steel packaging provides excellent protection against moisture, light, and air, ensuring product integrity and extending shelf life. Additionally, steel is highly sustainable as it can be recycled indefinitely, making it an environmentally friendly choice for packaging materials.

- Q: What are the different types of steel coils and their applications?

- There are several types of steel coils used for various applications. Hot rolled steel coils are commonly used in construction, automotive, and manufacturing industries due to their strength and versatility. Cold rolled steel coils are ideal for precision engineering, appliances, and electrical components as they offer a smooth finish and enhanced dimensional accuracy. Galvanized steel coils are coated with zinc to prevent corrosion and are commonly used in roofing, fencing, and automotive parts. Stainless steel coils are known for their resistance to corrosion and heat, making them suitable for applications in the food processing, medical, and chemical industries.

- Q: How is steel wire galvanized for wire rope applications?

- Steel wire is galvanized for wire rope applications through a process called hot-dip galvanization. In this process, the steel wire is immersed in a bath of molten zinc, which forms a protective coating on its surface. This coating provides excellent corrosion resistance, making the wire rope suitable for use in various applications, including construction, marine, and industrial sectors.

- Q: What are the different grades of tool steel and their applications?

- Tool steel is a type of high-quality carbon or alloy steel that is specifically designed for use in the manufacturing of tools and machinery parts. There are several different grades of tool steel, each with its own unique properties and applications. Some common grades include: 1. O-1 Tool Steel: This grade is known for its excellent hardness, wear resistance, and toughness. It is commonly used in making cutting tools, punches, and dies. 2. A-2 Tool Steel: A-2 grade offers good wear resistance and machinability. It is often used in applications requiring high production rates and precision, such as forming dies and precision measuring tools. 3. D-2 Tool Steel: D-2 grade is a high-carbon, high-chromium, and high-molybdenum steel. It exhibits excellent wear resistance and can retain its hardness even at high temperatures. It is widely used in making cutting tools, shear blades, and cold work punches. 4. H-13 Tool Steel: H-13 grade is a hot work tool steel with excellent heat resistance and high toughness. It is commonly used in applications that involve high temperatures, such as die casting, extrusion, and hot forging. 5. M-2 Tool Steel: M-2 grade is a high-speed tool steel known for its exceptional hardness and heat resistance. It is commonly used in making drills, reamers, and other cutting tools that require high-speed machining. These grades are just a few examples, and there are many other tool steel grades available, each suited for specific applications. The choice of grade depends on factors such as the desired hardness, wear resistance, toughness, and the specific tool or part being manufactured.

- Q: What are the advantages of using steel for construction purposes?

- There are several advantages of using steel for construction purposes. Firstly, steel is incredibly strong and durable, making it capable of withstanding heavy loads and extreme weather conditions. Additionally, steel is a flexible material that can be easily molded into various shapes and sizes, allowing for versatile and creative designs. Moreover, steel is resistant to fire, corrosion, and pests, ensuring the longevity and safety of the structure. Furthermore, steel construction is faster and more efficient compared to traditional methods, reducing construction time and costs. Lastly, steel is a sustainable option as it is recyclable, minimizing environmental impact.

- Q: What are the advantages of using steel plates in manufacturing?

- There are several advantages to using steel plates in manufacturing. Firstly, steel plates have high strength and durability, making them ideal for applications that require robust materials. Secondly, steel plates offer excellent resistance to corrosion, ensuring their longevity and suitability in various environments. Additionally, steel plates have good formability, allowing for customization and shaping to meet specific manufacturing requirements. Lastly, steel plates are readily available and cost-effective, making them a cost-efficient choice for many manufacturing processes.

Send your message to us

FLAT STEEL WIRE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords