Fireclay Brick - Standard Dimensions for Blast Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Refractory brick is a block of refractory ceramic material used in lining furnaces, kilns, fireboxes, and fireplaces.

We provide high quality Refractory Fire Bricks that are used on wide range in the various industries like Cement, Glass and Steel. Refractory Fire Bricks are provided as per the quantity and specifications required by the customers. We provide an extensive range of Refractory Fire Bricks at reasonable prices that depend upon the quantity ordered.

Main Feature:

The main chemical components: Al2O3 content is 30%-48%, SiO2 content is 50%-65%, and a small number of alkali metals, metal oxides, etc. Mineral composition is usually mullite, quartz and glass phase. Its refractoriness is 1580-1750 °C, refractoriness under load is 1250-1450 °C, with good thermal resistance and strong ability to resist acid slag.

Fire Clay Bricks is used for lower parts of regenerators, hot blast stove, furnaces of metallurgic, building material, glass, ferrous metal and so on.

Product Applications:

1. Furances of glass,coke oven,electric and so on

2.Furnaces of metallurgy industry, heat treatment furnace

3. Furnaces of chemical industry and construction industry.

4. Furnace of incineration of garbage, recirculating fluidized bed furnace

5. Standard sizing: 230 x 114 x 65 or 75 or 25 mm others up to the client

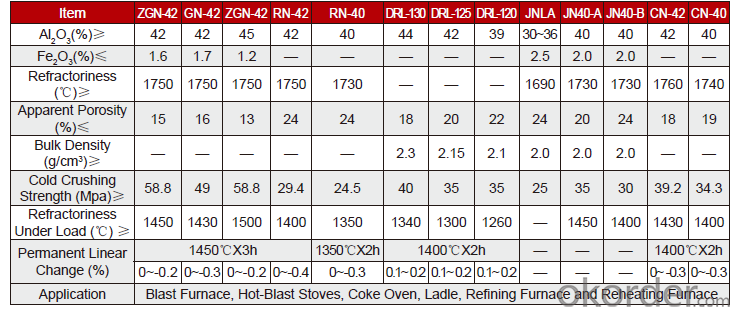

Specifications

1. Fire Caly brick Manufacturer

2. ISO 9001 certificate

3. Credible Quality

4. Reasonable price

5. Delivery in time

Technical data:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Which thermal stability of clay bricks and high alumina bricks is good?

- Thermal shock stability is much better than clay brick.

- Q: What's the difference between a high aluminum brick and a clay brick, two?

- Light clay brick, refractory material is a kind of high porosity, low density, low thermal conductivity of refractory material, refractory materials called lightweight refractories, it includes insulating refractory products, refractory fiber and refractory fiber products. Heat insulation refractory material is characterized by high porosity, general 40%-85%, low volume density, lower than 1.5g/cm3, low thermal conductivity, generally lower than 1.0W (m.K). The utility model has the function of heat insulation of an industrial furnace, and can reduce the heat dissipation loss of the kiln, save energy, and can reduce the quality of the thermal engineering equipment. The mechanical strength, wear resistance and slag resistance of insulating refractory material are poor, and it is not suitable for the load-bearing structure of kiln and direct contact with slag, burden, molten metal and other parts.

- Q: is it good to use firebricks to preserve the heat of rto furnace? Is there any other good ideas?

- 1. what variety and grade of refractory materials should be chosen to build all parts of the industrial furnace?; 2. is the origin of these materials be assured? mesothern resistance furnace, lightweight refractory brick, refractory fiber, bead brick of 1000 degrees; fuel heating furnace, refractory clay brick, high alumina brick, silica brick, carborundum brick, refractory castable, the plastic refractory of 1300 degrees; heat treatment furnace, refractory clay brick, refractory fiber of 1100 degrees; high temperature salt bath furnace, refractory clay brick, high alumina brick, zircon brick, refractory castable of 1300 degrees; high temperature resistance furnace, lightweight refractory brick, high aluminum bricks, lightweight alumina brick, lightweight refractory clay brick of 1400 degrees; molybdenum wire furnace, alumina brick, corundum brick, carborundum brick, finished alumina hollow ball product of 1650 degrees; cupola, refractory clay brick, carborundum brick, dolomite Brick, carbon brick, graphite brick of 1650 degrees; arc furnac, high alumina brick, silica brick, magnesia brick, magnesia brick, magnesia chrome... Corundum brick, carbon brick, magnesia chrome brick, magnesia brick, high aluminum brick, silica brick, finished alumina hollow ball product of 1700 degrees; cupola, refractory clay brick of 1650 degrees;

- Q: What is the problem about splintering when the refractory brick is fired?

- There are many bubbles inside the refractory brick, it is also possible that the brick itself is not up to the standard about volume density, then refractory brick fragmentates. There are many reasons, may be in the process of repression

- Q: What are the differences between sintered bricks and refractory bricks?

- Easily weathered. There is no obvious difference in the usage between fired pavingbricks and refractory bricks; sintered bricks are generally used for residential road and landscape engineering, they do not fade; refractory bricks are used for all kinds of kiln constructions in plant: It is not anti-freeze (when the temperature is below the zero degree, the brick will easily "blister" in the saturated state), the reasons are high compressive strength and high temperature zone' heat insulation and so on. Fired pavingbrick is a powerful vacuum extrusion type. Fire suppression road brick is high temperature furnace brick, which is not suitable to be used as road brick. Its characteristics are: Wear resistance and freeze-thaw resistance (the anti freeze-thaw cycle of brick is more than 50 times in saturated state), non weathering, sidewalks, short service life. Sintered brick belongs to the building material, refractory brick belongs to the industrial kiln material, which is easy to moss

- Q: do the used refractory bricks pollute the environment?

- the main pollution of refractory brick is coal gas pollution in the process of burning , it can be recycled to produce aggregate, waste brick has no pollution.

- Q: What is the difference between a clay brick and a red brick?

- Burning bricks are generally low temperature clay brick, brick, brick high.

- Q: What matters should be noticed when using clay refractory bricks in a glass kiln?

- There are a variety of products for the production of shaped and unshaped refractory clay, such as blast furnace insulation and high alumina bricks. Brick products include refractory clay bricks, plastic materials for overload, refractory clay and high alumina casting materials, etc.. In the amorphous part, if to support the horizontal induction furnace and the straight induction furnace lining, such as refractory clay and high alumina plastic

- Q: What kinds of annealing furnace refractory bricks there are?

- But the energy saving effect is good, but also can use lightwight heat insulating brick, but the price is higher than that of clay brick

- Q: does 90m high reinforced concrete chimney need firebrick?

- The chimney need firebricks or casting fire or acid resisitant concrete after casting, one aim is to resist high temperature, then is to resist acid corrosion. there is a variety of models of the refractory brick , you can refer to the installation quota.

Send your message to us

Fireclay Brick - Standard Dimensions for Blast Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords