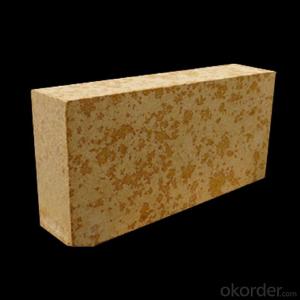

Fireclay Brick - High Strength Refractory Silica G98

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SILICA BRICK G98 for Hot-Blast Stoves

CMAX Silica bricks are made from high quality quartz tail sand, lime and mineralizing agent through the process of crashing, screening, mixing, pressing, drying and sintering.

Application

CMAX Silica bricks are commonly applied in coke oven, hot blast stoves, glass furnace etc.

Features

High refractoriness under load

High mechanical strength

Excellent thermal shock resistance

Corrosion resistance.

Good resistance against acid slag

High mechanical strength

Stable performance under high temperature environment

Applications:

Breastwall, regenerator, arch block, etc. In glass furnace

Carbonization chamber, combustion chamber in blast furnace

CMAX Silica bricks are made from high quality quartz tail sand, lime and minaralizing agent through the process of crashing, screening, mixing, pressing, drying and sintering.

- Q: There are various refractory materials inside many kilns such as refractory brick, what is the role of masonry of these refractory materials?

- High temperature prevention, warmth keeping and heat insulation.

- Q: What kind of refractory brick is suitable for 24*28m rotary kiln of 5,000 tons?

- 24~28 meters belongs to the transitional zone, magnesia spinel brick or silicon carbide brick (Series)

- Q: how much is the content of the high alumina of refractory brick?

- linear?change?on?reheating is small and Slag resistance is good, matte smelting, good thermal shock resistance used refractory materials should be resistant to high temperature: In front of the furnace, the temperature can reach 1800, copper blowing. The maximum temperature in the smelting furnace area is on the top, pyro-refining and electrorefining, magnesia chrome brick, magnesia chrome castable, magnesia alumina brick. The commonly used refractory materials is direct-bonded?magnesia-chrome?bricks, which has large volume density. manufacturing technique of copper smelting consists of five parts, Clay brick

- Q: What are the main raw materials of refractory brick and runner brick?

- Category of refractory , runner brick mainly is clay brick

- Q: What is the difference between clay brick, glazed tile and brick?

- Clay bricks are actually a kind of clay bricks, mainly made of solid bricks! It is a product of continuous optimization of products and upgrading of traditional techniques. Usually made of high quality clay and clay brick clay high temperature firing, using natural clay as main component, quartz and feldspar as aggregate, construction bricks after sintering the formed. The nature of clay brick belongs to low temperature brick, the burning temperature is about 800 degrees Celsius, the water absorption rate is higher, and the general water absorption rate is 8%--10%.

- Q: The foundation is made of Mu10, which is new clay brick and M7.5 cement mortar. What does it mean?

- MU10 is the strength of bricks, and M7.5 is the strength of cement mortar.

- Q: What is the clay used to make the refractory brick?

- Lining brick of teeming ladle; refractory clay used in building materials industry to produce high alumina bricks for cement kilns and glass furnaces, as well as anti sliding, high alumina lining bricks and high alumina refractory clay. The hard clay in refractory clay is used for making blast furnace refractory material, which is used in agriculture as a fertilizer promoting agent and, and electron. High alumina clay is also used in the oil well, generally does not disperse in water. In metallurgy, accounts for 2/3 of abrasive products, and so on. Hard clay and semi hard clay can be used to manufacture daily-use ceramics. High alumina clay after calcination, which has high temperature resistance! Refractory clay refers to the degree of fire resistance is greater than 1580, the hardness and proportion is relatively big, the refractoriness is good. They except has relatively high refractoriness. Such as aluminum sulfate, its dosage accounts about 70% of all the refractory materials;

Send your message to us

Fireclay Brick - High Strength Refractory Silica G98

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords