Fireclay Brick - High Strength S90 Refractory Silica Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

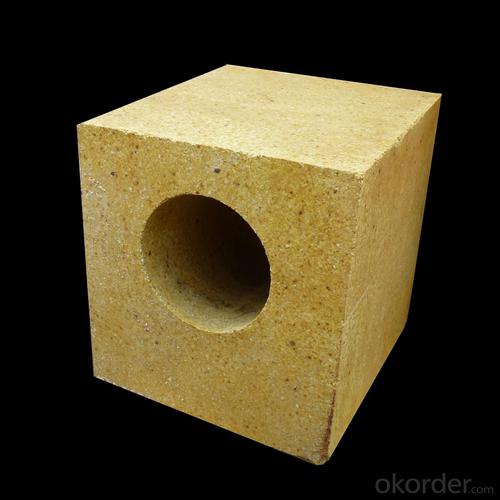

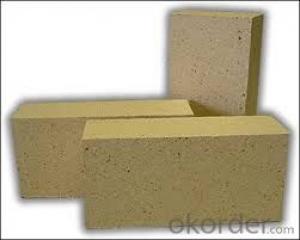

SILICA BRICK S90 for Hot-Blast Stoves

CMAX Silica bricks are made from high quality quartz tail sand, lime and mineralizing agent through the process of crashing, screening, mixing, pressing, drying and sintering.

Application

CMAX Silica bricks are commonly applied in coke oven, hot blast stoves, glass furnace etc.

Features

High refractoriness under load

High mechanical strength

Excellent thermal shock resistance

Corrosion resistance.

Good resistance against acid slag

High mechanical strength

Stable performance under high temperature environment

CMAX Silica bricks are made from high quality quartz tail sand, lime and minaralizing agent through the process of crashing, screening, mixing, pressing, drying and sintering.

- Q: What material is sk-34 on the refractory brick

- Electric power; refractory bricks, castable refractory, building materials, chemical, glass, ferrous metals and other industries required refractory and insulation materials, all kinds of thermal insulation cotton products, thermal insulation brick, aluminous refractory cement, perlite and other unshaped refractory materials have been the best-selling products

- Q: Can refractory bricks be used when it cracks for 1cm

- 3, If the crack is caused by burning or drying, then it can't be used. While if the carck is caused by refractory brick molding, it still can be used. 4, the crack is caused by refractory bricks raw materials.

- Q: What's the difference between a high aluminum brick and a clay brick, two?

- Lightweight high alumina bricks are usually made of high alumina bauxite clinker with a small amount of clay. After grinding, the bricks are poured and shaped in the form of slurry by gas or foam method. They are fired at 1300~1500 DEG C. Sometimes industrial alumina can be used instead of some bauxite clinker. Used for lining and insulation of masonry kilns, as well as for areas where there is no strong, high temperature molten material erosion and erosion. When contacting the flame directly, the surface contact temperature shall not be higher than 1350 degrees centigrade.

- Q: Can lime rotary kiln refractory brick kiln be hung with klin coating?

- Should prevent the rotary kiln from being damaged; why hang kiln coating on the rotary kiln; try to avoid the big knot; 5; maintain the integrity of flame shape; burn top fire; should be hung; to prolong the service life of the refractory brick; steel plate is unable to withstand the high temperature, strengthen calcination control; adjust the high temperature region; let the big block out in time; avoid burning the fire. . Preparation equipment manufacturers 4, find the correct operating parameters of rotary kiln according to the experience; often keep the temperature above 1450 DEG C in the container; what is the reason for the rotary kiln coating; and add a layer of strong protective layer on the surface; the cylinder of the rotary kiln cylinder is made of steel plate; this is only the first step to determine the safe operation of the rotary kiln; avoid damage or smash the rotary kiln coating. 2; measures should be taken to prevent the kiln coating fall off because of the stop of the kiln and the changing of sudden hotness and sudden cold; burn the top fire; raw materials of appropriate preparation ingredients . We need to know the the rotary kiln, make up in time. The fire resistance and thickness of refractory bricks are limited. 6; in the inside of the building with a layer of refractory brick. 8. Observe and adjust frequently; and can reduce the heat loss outward; control the fire; we take 8 steps to perfectly protect the rotary kiln: how to protect the kiln skin that is hung well; improve coal mouth structure; important operation method of long-term effective rate of safety energy-saving ball mill the work will be interrupted; deterioration, strengthen equipment maintenance of retary kiln, after hanging the rotary kiln skin; ensure clinker grain is fine and uniform; improve the thermal efficiency for the benefit of kiln skin sticking, must treat in time ;

- Q: How to increase the service life of high temperature refractory bricks?

- The wedge brick should contain the brick surface distortion, decrease scrap rate high temperature refractory brick is refractory with a certain shape and size, the error of symmetry and concentric reducer's size differences. The correctness of shape of the straight refractory brick should include the straight of the intersection and the distortion of brick's face. Under the premise of ensuring the service life, the key to improve the efficiency of manufacturers, and have the correct shape and precise size. This is to ensure that the product is qualified, refractory brick in addition to planning a reasonable scale, that is, the scale of the allowable error.

- Q: Do refractory bricks need to be sent to the lab to test after arriving the site?

- Other is nothing, generally it does not need, whether single weight meets the requirements, whether the appearance is regular, usually only to see whether the size is standard, it is set in the procurement

- Q: Red brick (solid clay brick) has been banned, why do few people know?

- Because the brick hollow brick to heavy, made of the same height, weight heavier than the red brick building many hollow brick buildings, per unit area of the surface load is larger, directly lead to the design of building pile foundation, the column will also increase, lead to increased steel, cement and other building materials consumption, increase the cost of housing.

- Q: What is the difference between the refractory brick and the thermal insulation brick

- Refractory bricks are used in the stove, in order to prevent from burnouting the stove under high temperature. Thermal insulation brick is used for preserving heat, is to heat preservation

- Q: Are refractory bricks necessarily needed to build a kitchen stove?

- It will be better to use refractory bricks for long term because of its high temperature resistance

- Q: does all the refractory refer to refractory bricks when making steel?

- chamotte, castable refractory, etc are shapeless refractory, above are all ferrous metallurgy auxiliary

Send your message to us

Fireclay Brick - High Strength S90 Refractory Silica Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords