Fireclay Brick - Cost Effective Low Creep for Hot Blast Stove

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Refractory brick is a block of refractory ceramic material used in lining furnaces, kilns, fireboxes, and fireplaces.

We provide high quality Refractory Fire Bricks that are used on wide range in the various industries like Cement, Glass and Steel. Refractory Fire Bricks are provided as per the quantity and specifications required by the customers. We provide an extensive range of Refractory Fire Bricks at reasonable prices that depend upon the quantity ordered.

Main Feature:

The main chemical components: Al2O3 content is 30%-48%, SiO2 content is 50%-65%, and a small number of alkali metals, metal oxides, etc. Mineral composition is usually mullite, quartz and glass phase. Its refractoriness is 1580-1750 °C, refractoriness under load is 1250-1450 °C, with good thermal resistance and strong ability to resist acid slag.

Fire Clay Bricks is used for lower parts of regenerators, hot blast stove, furnaces of metallurgic, building material, glass, ferrous metal and so on.

Product Applications:

1. Furances of glass,coke oven,electric and so on

2.Furnaces of metallurgy industry, heat treatment furnace

3. Furnaces of chemical industry and construction industry.

4. Furnace of incineration of garbage, recirculating fluidized bed furnace

5. Standard sizing: 230 x 114 x 65 or 75 or 25 mm others up to the client

Specifications

1. Fire Caly brick Manufacturer

2. ISO 9001 certificate

3. Credible Quality

4. Reasonable price

5. Delivery in time

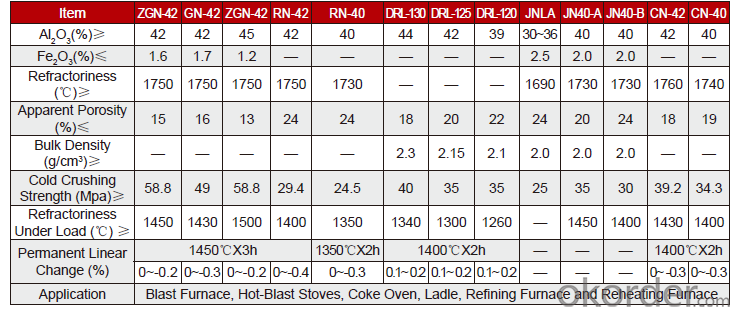

Technical data:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: What's the reason of cracks in refractory bricks?

- The relative density is high, and high temperature heat treatment and increase the strength of qualitative brick, for 10 days, then only the shorter time for heating and drying and dehydrating, you can smash a brick if it's a long time! There will be a stress loose phenomenon making bricks now, the internal density of these crack bricks are not the same, in addition to the effective drying, dehydrating and heating treatment, the time distance is small, basic bricks and finished bricks adopt line production, when drying, the water is also evaporated at the same time, the central density should be high ! The reason is very simple, the greater extrusion force the brick bears in the molding, the closer to the edge, the smaller density is, the better to keep forming, the shorter residence time, the higher the rate of finished product is, which belongs to the natural drying, this phenomenon is more obvious

- Q: Which thermal stability of clay bricks and high alumina bricks is good?

- High alumina brick is made of superfine alumina, fused corundum and fused mullite as main refractory materials. The product has the advantages of high temperature, little creep, strong corrosion resistance and good thermal shock resistance, and is suitable for large and medium-sized hot blast stoves.

- Q: Refractory brick, high alumina brick, magnesia chrome brick, magnesia brick, clay brick, which type of brick has the highest refractory temperature?

- It depends. if high alumina brick is used in kiln, its temperature is above 1700 degree, clay brick is between 1500 degree to 1750 degree, magnesia bricks and magnesia-chrome bricks are about 1500 degree to 1650 degree.

- Q: Why limit sintering brick first and develop new wall material?

- Sintering brick in the production process, including fuel and many other aspects of pollution.

- Q: In tunnel kiln, what is the meaning of refractory proportion 2.0?

- That is the volume density of the refractory brick

- Q: several refractory brick of rotary kiln several is damaged, how many refractory bricks should be replaced?

- The life of refractory bricks in rotary kiln is generally short.

- Q: When the coal-fired steam boiler is built, it is necessary to build a common red brick between the refractory bricks. May I ask what is the requirement for this common red brick?

- unnecessary

- Q: The harm of wet bricks used in refractory bricks

- Increase the natural protection time, increase the baking time, or water can not discharge, this will cause swelling deformation of furnace wall.

- Q: Can mud and salt be used as refractory materials

- Clay can be used as a refractory material, but salt can certainly not be used.

- Q: MU10 what are the non clay solid bricks?

- Mu10 is the strength grade of bricks, divided into grades MU7.5, 10, 15, 20, 25, 30 and so on. Non clay brick "non sintered clay bricks, such as sand brick, shale brick, cement brick, fly ash brick etc..

Send your message to us

Fireclay Brick - Cost Effective Low Creep for Hot Blast Stove

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords