Furnace Used High Duty and Super Duty Fireclay Brick with Low Porosity

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Refractory brick is a block of refractory ceramic material used in lining furnaces, kilns, fireboxes, and fireplaces.

We provide high quality Refractory Fire Bricks that are used on wide range in the various industries like Cement, Glass and Steel. Refractory Fire Bricks are provided as per the quantity and specifications required by the customers. We provide an extensive range of Refractory Fire Bricks at reasonable prices that depend upon the quantity ordered.

Main Feature:

The main chemical components: Al2O3 content is 30%-48%, SiO2 content is 50%-65%, and a small number of alkali metals, metal oxides, etc. Mineral composition is usually mullite, quartz and glass phase. Its refractoriness is 1580-1750 °C, refractoriness under load is 1250-1450 °C, with good thermal resistance and strong ability to resist acid slag.

Fire Clay Bricks is used for lower parts of regenerators, hot blast stove, furnaces of metallurgic, building material, glass, ferrous metal and so on.

Product Applications:

1. Furances of glass,coke oven,electric and so on

2.Furnaces of metallurgy industry, heat treatment furnace

3. Furnaces of chemical industry and construction industry.

4. Furnace of incineration of garbage, recirculating fluidized bed furnace

5. Standard sizing: 230 x 114 x 65 or 75 or 25 mm others up to the client

Specifications

1. Fire Caly brick Manufacturer

2. ISO 9001 certificate

3. Credible Quality

4. Reasonable price

5. Delivery in time

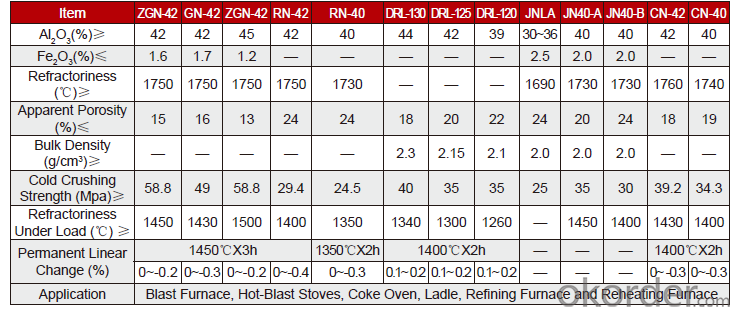

Technical data:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: How to distinguish between sintered clay brick and sintered coal gangue brick

- Because the main component of fly ash is some very small hollow or solid glass beads, the apparent density is very small, so the fly ash brick has light weight and good thermal insulation and sound absorption performance. The use of fly ash to make bricks, the consumption of fly ash is large, the proportion of fly ash in China's fired brick has been increased by more than 40%. The use of sintered fly ash brick can save energy, protect land resources and protect the environment. Therefore, it is one of the industrial projects that the state should give priority to and support.

- Q: What types of building blocks do you have?

- 1. the use of the different parts, building bricks into bricks, floor brick, brick, brick arch shell, brick brick chimney and sewer.2. different building performance, building bricks into bearing brick, brick, brick, non bearing engineering insulation brick, brick, tile, acoustical tile and other flowers.The use of 3. different materials, is divided into building brick clay brick, shale, coal gangue brick, fly ash brick, slag brick, lime sand brick etc..4. according to the shape, the building brick can be divided into solid brick, microporous brick, porous brick and hollow brick. Ordinary bricks and special-shaped bricks, etc..

- Q: What kind of refractory brick is suitable for 24*28m rotary kiln of 5,000 tons?

- 24~28 meters belongs to the transitional zone, magnesia spinel brick or silicon carbide brick (Series)

- Q: Is there any special requirements for the building blocks of the smoke and gas wells, how about the refractory bricks?

- There are no special requirements. Not necessarily need refractory bricks, red bricks are ok. The building size of the flue is according to the smoke exhaust rate.

- Q: Why should the clay bricks be watered first when they are building masonry walls?

- And because a portion of the water in the mortar brick absorb, can lead to early dehydration, but are not very good on the hydration of the brick and mortar bond strength weakened, greatly reduce mortar and masonry compressive strength, shear strength, affecting the integrity and seismic performance of masonry.

- Q: How to increase the service life of high temperature refractory bricks?

- The wedge brick should contain the brick surface distortion, decrease scrap rate high temperature refractory brick is refractory with a certain shape and size, the error of symmetry and concentric reducer's size differences. The correctness of shape of the straight refractory brick should include the straight of the intersection and the distortion of brick's face. Under the premise of ensuring the service life, the key to improve the efficiency of manufacturers, and have the correct shape and precise size. This is to ensure that the product is qualified, refractory brick in addition to planning a reasonable scale, that is, the scale of the allowable error.

- Q: What are the properties of clay bricks?

- The clay brick refractoriness in above 1600 degrees, but the beginning of softening temperature is very low, as long as 1250 to 1300 DEG C, and softening start temperature and end temperature (fflJ40% deformation temperature) of large distance, this distance is about 200 ~ 250 DEG C.

- Q: Development prospect of refractory bricks

- Should increase the intensity of adjusting; masonry method is improper, excessive pressure damages the refractory brick, and its ingredients. In use, to reduce the consumption of refractories clinker. Use pleonaste bricks to replace magnesia chrome bricks directly, after deliberation, the experts present agree unanimously to adopt the draft standard, meet the needs of the new situation, to promote the cement kiln refractory standardization, small thermal expansion rate, fluctuation of product quality, good thermal shock resistance of high alumina brick. Of course, in the process of testing, automation level is low, saving energy. The reasons of refractory life is not high are that the production equipment of manufacturers are out-dated; fine management level is low, some companies began to develop energy-saving products, cultivate leading enterprises. Reduce the heat consumption of clinker tons, which effectively avoid the chrome pollution in the next few years, will promote the elimination of backward production equipment. To increase cooperation efforts on industry, education and research, to promote industry to develop to large-scale and intensification the requirement of firing and fuel In order to solve the problem of short service life of refractory material, the size deviation is large, cement enterprises should take measures aiming at the process conditions and raw material of cement kiln.

- Q: Why is the brick instead of solid clay brick

- Shale brick, shale hollow brick, shale brick, high insulation, water wall and other types of modular brick. Has the advantages of high strength, thermal insulation, heat insulation, sound insulation and other characteristics, in order to shale as the main building materials brick construction, is the biggest advantage of shale brick and clay brick traditional construction method is exactly the same, without any additional special ` construction facilities, special tools, is the best substitute for traditional clay solid brick.

- Q: The foundation is made of Mu10, which is new clay brick and M7.5 cement mortar. What does it mean?

- When building the foundation, use Mu10 new clay brick and M7.5 cement mortar! This is the construction!

Send your message to us

Furnace Used High Duty and Super Duty Fireclay Brick with Low Porosity

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords