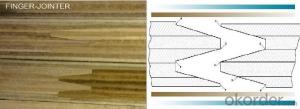

CDX Plywood Finger Jointed Core Film Faced Plywood Shuttering Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specification:

Item name:Black/Brown Film Faced Plywood

Size:1220*2440/1250*2500

Core: poplar/hardwood/combi/birch

Glue: WBP, melamine, phenolic

Description:

Size | 1220x2440mm,1250x2500mm,1830 x 915mm |

Thickness | 5mm--25mm |

Glue | MR,E1,E2,Melamine,WBP |

Core | Poplar,birch,combic,hardwood,eucalyptus, |

Face&back | Okoume,bintangor,birch,pine,agathis,pencil-cedar,bleached poplar,black/brown film |

Thickness | minus or plus 0.2mm--0.5mm |

Moisture content | 8%--12% |

Grade | Packing grade&furniture grade |

Quantity | 8pallets/20ft,16pallets/40ft,18pallets/40HQ |

Payment term | T/T or L/C at sight or D/P or D/A |

Min order quantity | 1x20ft |

Delivery time | 15—20 days upon the receipt of 30% tt deposit or l/c at sight |

Packaging | Inner plastic bags,outer three-ply or paper-box,wrapped with steel tapes by 4x6 lines for reinforce |

Supply ability | 3500 CUB/month |

Certificate | FSC,CE,CARB,ISO9001:2000 |

Features:

1. The face should be of high resistance to corrosion and moisture.

2. The face should be smooth and easy to take off from cement and easy to clean.

3. The core should be water resistant and won’t swell.

4. The core should be strong enough and won’t break.

5. The edge should be sealed and water proof.

Advantages of our film faced plywood

1. Above 18mm thickness film faced plywood , could be used 20 time at least

2. The inside each veneer is whole core

3. Each veneer is glued totally

4. Boiled for 10 hours , will not cracking

5. Twice hot press to strong joining capacity

6. Cold press again to strong joining capacity

7. 100% Dry

8. We have another glue making factory

FAQ

A. Quality :

With the skilled worker ,mature technology and ten years experience ,all our plywood are steady quality .

B. Price:

Due to the skilled worker ,mature technology and an experienced operating system , we can

quote you competitive price , so that you will have the price advantage to capture your market.

C.Service:

7*24hours , if any need, you can email or call us,we will do our best to meet your demand

D.Export experience:

Over ten years experience for exporting ,We are much familiar with

the export operation .

- Q: Selection of plywood in plywood production

- Natural wood veneer is made of precious natural wood, veneer or cut by the processing of veneer veneer

- Q: How to use building plywood?

- Building plywood is mainly used in outdoor conditions, such as building decoration and concrete template

- Q: Furniture solid wood and plywood which is better? Such as bed `wardrobe` TV cabinet `table

- the difference between the process: multi-layer solid wood flooring will be a layer of each layer of scientific criss-cross, to eliminate internal stress, at present, its layers have grown from 7 to 9 layers, 11 layers

- Q: What harm does the plywood factory work?

- Occupational acute benzene poisoning is the workers in the professional activities, short-term inhalation of high-dose benzene vapor caused by the central nervous system suppression as the main manifestation of systemic diseases

- Q: Material for the plywood defects which

- Decay rot due to the invasion of wood rot fungi, the cell wall material decomposition, resulting in loose wood, strength and density decreased, wood tissue and color are often changing.

- Q: Today, most of the furniture is made of wood, pine, bakelite and popla

- As these high quality woods become increasingly scarce and expensive, people begin to make furniture with easier access to wood, and those good wood is already very rare

- Q: What is the plywood made of wood?

- Production of plywood main tree species are: camphor, willow, poplar, eucalyptus, fir and so on

- Q: For the plywood environmental advice?

- According to the environmental protection level, the glue used for plywood can be divided into E0 grade, E1 glue, E2 glue (and even E2 level are not reach the unqualified glue)

- Q: Solid wood and plywood which is better?

- Can not completely determine which is better, this depends on how you use the main.

- Q: Poisoning diagnosis and grading standards

- can also have abnormal growth, reference operating environment investigation and field air concentration determination of benzene, comprehensive analysis

Send your message to us

CDX Plywood Finger Jointed Core Film Faced Plywood Shuttering Plywood

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 20000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords