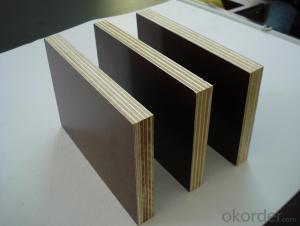

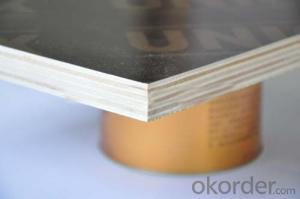

Film Faced Plywood Phenolic Film Faced Plywood Black 18mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of products Description:

Type:Plywoods

Place of Origin:Shandong, China (Mainland)

Brand Name:topwood

Usage:Outdoor

Grade:First-Class

Main Material:Poplar

Formaldehyde Emission Standards:E2

Plywood Type:12-Ply Boards

name:bamboo film faced plywood

key words:film faced plywood

basic feature: film faced plywood with high quality

Main Features of the products:

1) High bending strength

2 ) Little linear expansion conefficient

3) Strong nail holding

4) Moistureproof and easy work

5) Tight construction and high strength

6) No ratten or decay

7) Low formaldehyde emission

8) The produces are suitable for the construction of viaduct and tall frame buliding

9) If used abide by the illustration strictly, it can be reused more than 50 times.

Specification:

core:Poplar/birrch/hardwood/combi

Glue:MR/melamine/WBP

size: 1220mmx2440mm/610mmx2440mm/1250mmx2500mm

thickness:8mm/9mm/12mm/15mm/18mm/20mm or as requested

reuse:Above 12 times

modulus of repture:More than 30Mpa

modulus of eslticity:>=6000Mpa

Images:

- Q: Eps sandwich board and Caigang sandwich board is not two kinds of materials to the two of the price?

- Is the same product! Just called different.

- Q: OKorder Caigang sandwich panels, foam sandwich panels, manufacturers production? Price concessions

- To price less water, you have to find manufacturers to buy, the amount of more affordable, do not know which area you are in?

- Q: Will the color steel sandwich panels how to install the above doors and windows how to install?

- Do not recommend yourself to get, unsafe, you can sell your people to call the master will be cheaper

- Q: The concept of glass wool cotton sandwich panels

- Composite methods are usually explosive composite, explosive rolling composite, rolling composite and so on. Composite materials can be divided into composite panels, composite pipe, composite bar and so on. Mainly used in anti-corrosion, pressure vessel manufacturing, electric construction, petrochemical, pharmaceutical, light industry, automobile and other industries. Composite material according to the appearance can be divided into composite panels, composite pipe, composite bar and so on.

- Q: Does the color steel sandwich panel plant require an environmental permit?

- (1) a copy of the application form for environmental management of the construction project; (2) the registration form of the proposed environmental impact of the project; (3) the project proposal and the relevant department approval document of the project proposal; (4) Topographic map, the map should be marked around the proposed project; (5) the proposed project to be approved by the local Environmental Protection Agency.

- Q: Can the rock wool sandwich panel be used as a ceiling?

- Rock wool sandwich panels can do ceiling. Ceiling (English name: sprung roof) refers to the housing living environment of the top decoration. Simply put, refers to the decoration of the ceiling, is an important part of interior decoration. Ceiling with insulation, insulation, sound insulation, sound absorption of the role, but also electrical, ventilation and air conditioning, communications and fire, alarm pipeline equipment and other projects hidden layer. Home decoration ceiling is a common part of home improvement. The ceiling is different according to the material of the decorative plate, and the classification is not the same. Ceiling decoration materials is the main basis for distinguishing the name of the ceiling, mainly: light steel keel gypsum board ceiling, gypsum board ceiling, mineral wool board ceiling, plywood ceiling, profiled long strip of aluminum slab ceiling, Glass ceiling, aluminum honeycomb perforation sound-absorbing panels such as ceiling. In the whole room decoration occupies a very important position on the top of the room for the appropriate decoration, not only to beautify the indoor environment, but also create a colorful interior space art image. In the choice of ceiling decoration materials and design programs, to follow the two materials, solid, safe, and beautiful, practical principles.

- Q: Because it was not promptly cleared, after the wind and sun, it is difficult to clear, because the area is relatively large, a little bit of clean up by hand very difficult, which experts have any good way not?

- 2. Board protection form: complex PVC protective film 【Features】 1. Advantages: good fire resistance, sound insulation better. Yanmian Caigang sandwich panel Features: Caigang rock wool composite board products for the A-class fire board 1. Good fire performance:

- Q: Will the rock wool sandwich board which manufacturers better?

- OKorder Zhongji Machinery Manufacturing Co., Ltd. R & D and production of rock wool polyurethane sandwich panel equipment, rock wool / EPS color steel sandwich panel equipment can produce a variety of different types of fire insulation sheet. Won the title of state-level high-tech enterprises, and the Ministry of Commerce was identified as designated equipment export manufacturers. After-sales service is good, but it is expensive point Oh

- Q: I am in OKorder because of procurement needs, would like to first understand the color steel factory in OKorder which manufacturers quality and cheap products! Worthy of lazy thanks!

- OKorder Bo Xing color steel company specializing in the production of rock wool sandwich panels, fire, waterproof performance is very good, the supply of a lot of large steel company, you are welcome to call us, absolutely high quality and cheap

- Q: What is the difference between the board and the core board?

- Big core board price is cheaper than the core board, the vertical (to the core material to distinguish) bending strength is poor, but the lateral bending strength than ... but generally do not choose the best! Plywood is made of three or more layers of 1mm thick veneer sheet made of hot pressing. Plywood is generally divided into 3mm, 5mm, 9mm, 12mm, ... plywood buy plywood by multi-layer single The plates are arranged in a crisscross arrangement. The outermost front panel is called a panel, and the back is called a backplane. The inner board is called the core plate.

Send your message to us

Film Faced Plywood Phenolic Film Faced Plywood Black 18mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords