Fiberglass Mat Tissue Glass Wool Heat Insulation, Sound Proof, and Fireproof Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass Wool Blanket:

Glass wool sention pipe is a kind of economical insulating material which is light and easy to install. This material has excellent performance of heat and sound insulation under both extremely high and low temperature conditions. Therefore, ventilating ducts, industrial civial heat suppling and all kinds of heating, cooling pipelines.

Glass wool, which belongs to glass fiber , is a kind of man-made inorganic fiber. It is made from fibrosis glass melt in wool shape, which belongs to inorganic fiber and fiber in its chemical ingredient. Its merit is better in shape, low density and volume, low in thermal conduction, better heat preservation and thermal insulation, fine sound absorption, corrosion-resistant and stable chemical property.

2.Main features of Glass Wool Blanket:

1) Heat insulation and heat preservation, sound adsorption and noise reduction

2) Low slag indusion content, thin and long inner fiber

3) Thermal stability, stable and high efficiency for a long time

4) High temperature heat-stability, durability, high temperature shrinkage resistance

5) Damp proof property, with the hydrophobicity are not less than 98%

6) Excellent fire proof performance, European standard non-flammable class A material

7) Non-poison, not contain rock wool and doesn't grow the mould etc.

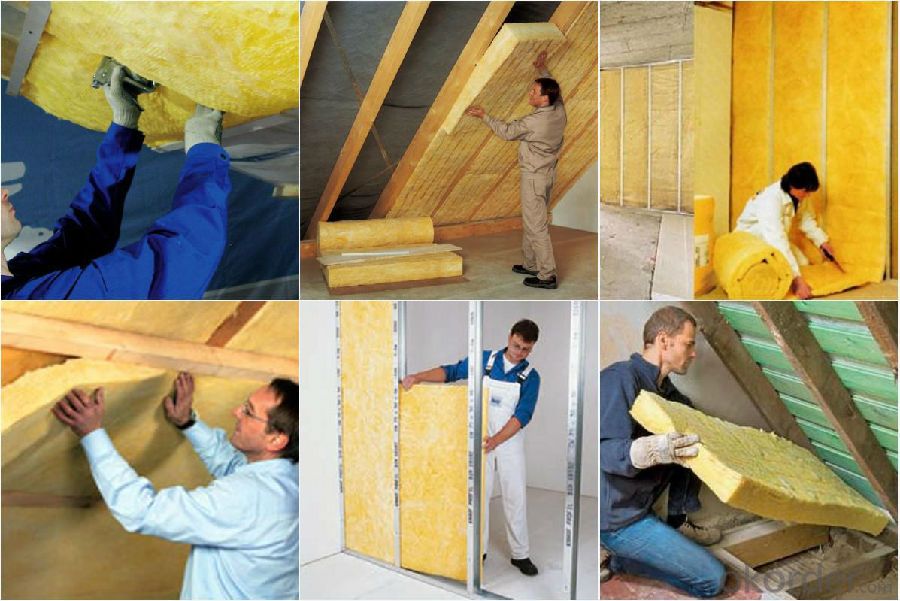

3.Glass Wool Blanket Images:

4. Glass Wool Insulation Blanket Technical Parameters:

Property | High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

Shape | According to your requirement. |

Color | Any color is available ,according to your requirements. |

Material | NBR, CR, SBR, EPDM, IIR, NR, EP, Silicone, VITON etc. |

Hardness | 30-90ShoreA |

Delivery | In 10 days |

Packing | Plastic bag & carton box or according to your requirements. |

Application | Electronic field, industrial machine & equipment, house-hold appliance, telecommunication, automobile, medical equipment industry etc. |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass Wool Blanket is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How does the roll diameter of fiberglass mat tissue affect its handling?

- The handling of fiberglass mat tissue can be significantly impacted by the diameter of the roll. When the roll diameter is larger, the roll becomes heavier and bulkier, which poses a greater challenge for handling and maneuvering. This is especially important when the fiberglass mat tissue needs to be transported or installed manually. Furthermore, lifting and moving a larger roll diameter requires more physical effort, putting strain on those handling it. Additionally, larger roll diameters occupy more space, making storage and transportation more complicated. On the other hand, a smaller roll diameter makes the fiberglass mat tissue easier to handle due to its lighter and more compact nature. This is particularly advantageous in situations that involve frequent movement and installation, such as construction sites or manufacturing facilities. Moreover, a smaller roll diameter allows for more efficient storage and transportation as it takes up less space and can be easily stacked. This optimization of logistics helps minimize the costs associated with storage and transportation. In summary, the roll diameter of fiberglass mat tissue directly impacts its handling characteristics. Larger diameters make handling more challenging, while smaller diameters provide easier handling and improved storage efficiency.

- Q: How long does fiberglass mat tissue last?

- The lifespan of fiberglass mat tissue varies depending on various factors such as the quality of the material, environmental conditions, and maintenance. However, on average, fiberglass mat tissue can last for several decades if properly installed and cared for.

- Q: How does fiberglass mat tissue perform in terms of chemical resistance?

- Fiberglass mat tissue generally exhibits excellent chemical resistance properties. The material is typically made from glass fibers that are held together by a binder, and this composition allows for resistance to a wide range of chemicals. Fiberglass mat tissue is commonly used as a reinforcement in composite materials, such as fiberglass-reinforced plastics (FRP), due to its ability to withstand exposure to various chemicals without degrading or deteriorating. The chemical resistance of fiberglass mat tissue can vary depending on the specific type and quality of the material, as well as the specific chemical being encountered. However, in general, it is highly resistant to most acids, alkalis, solvents, and other corrosive substances. This resistance makes it a suitable choice for applications where the material may come into contact with aggressive chemicals, such as in chemical processing plants, water treatment facilities, or storage tanks. It is important to note that while fiberglass mat tissue is generally chemically resistant, it may not be completely impervious to all chemicals. Some highly concentrated or specialized chemicals may still have the potential to cause damage or deterioration over time. Therefore, it is always advisable to consult the manufacturer's specifications and recommendations for specific chemical resistance information before using fiberglass mat tissue in a particular application. Overall, fiberglass mat tissue is known for its strong chemical resistance properties, making it a reliable choice for applications where exposure to chemicals is expected.

- Q: What are the advantages of using fiberglass mat tissue?

- The advantages of using fiberglass mat tissue include its high strength-to-weight ratio, excellent dimensional stability, resistance to corrosion, and ability to provide reinforcement to various materials. Additionally, fiberglass mat tissue is easy to handle and can be easily molded or shaped to fit different applications, making it a versatile choice in industries such as construction, automotive, and aerospace.

- Q: Is fiberglass mat tissue resistant to moisture?

- Fiberglass mat tissue, indeed, exhibits resistance to moisture. By tightly weaving strands of glass fibers and subsequently bonding them with a resin, this tissue fabricates a barrier that effectively thwarts the infiltration of moisture. Consequently, the moisture-resistant properties of fiberglass mat tissue render it exceptionally suitable for deployment in scenarios where water exposure or high humidity is anticipated. Moreover, this tissue's resistance to moisture aids in averting the proliferation of mold or mildew, thereby establishing it as an appropriate selection for environments prone to dampness.

- Q: Can fiberglass mat tissue be used for architectural applications?

- Yes, fiberglass mat tissue can be used for architectural applications. It is commonly used as a reinforcing material in architectural elements such as roofing, insulation, and wall panels. Its high strength, durability, and fire resistance make it suitable for various architectural purposes.

- Q: What are the different quality standards for fiberglass mat tissue?

- Various quality standards are utilized to evaluate the quality of fiberglass mat tissue, ensuring its suitability for intended applications and meeting performance requirements. The ASTM D2178 standard is widely used to assess the quality of fiberglass mat tissue. This standard outlines the specifications for base materials used in the production of asphalt and coal tar roofing products. It covers physical properties such as weight, thickness, tensile strength, tear resistance, and permeability. Another recognized standard is ISO 3376, which provides guidelines for determining the tensile properties of nonmetallic materials, including fiberglass mat tissue. It defines test methods for parameters like tensile strength, elongation at break, and modulus of elasticity. In Europe, the EN 1871 standard is commonly used for assessing the quality of fiberglass mat tissue. This standard specifies the requirements for reinforced bitumen sheets used in roofing applications. It covers physical properties, dimensional stability, resistance to heat, and resistance to aging. Furthermore, there are industry-specific quality standards that may apply to fiberglass mat tissue used in particular applications. For instance, the ASTM C1666 standard specifically addresses fiberglass reinforced cementitious panels and sets requirements for the materials used in their production. Overall, these various quality standards for fiberglass mat tissue ensure that it meets specific performance criteria and can be effectively utilized in applications such as roofing, construction, and insulation. They establish a framework for manufacturers, suppliers, and customers to assess and compare the quality of different products in the market.

- Q: Is fiberglass mat tissue fire resistant?

- Yes, fiberglass mat tissue is fire resistant. Fiberglass is made from a combination of glass fibers and resin, which gives it excellent fire-resistant properties. It has a high melting point and does not easily ignite or support combustion. Additionally, fiberglass mat tissue is often treated with fire-resistant coatings or additives to further enhance its fire-resistant capabilities. This makes fiberglass mat tissue a popular choice for various applications where fire resistance is required, such as insulation materials, protective clothing, and fireproof barriers.

- Q: Can fiberglass mat tissue be used for insulating refrigeration units?

- Fiberglass mat tissue is indeed suitable for insulating refrigeration units due to its lightweight nature and outstanding thermal insulation properties. It finds extensive use in a wide range of applications where insulation is necessary, including refrigeration units. By minimizing heat transfer, the fiberglass mat tissue ensures that the internal temperature of the refrigeration unit remains stable, safeguarding the stored items from any external heat. Moreover, its moisture-resistant capabilities are particularly crucial in refrigeration units as they prevent condensation and help maintain the cooling system's efficiency. All in all, fiberglass mat tissue proves to be a reliable and effective option for insulating refrigeration units.

- Q: Can fiberglass mat tissue be recycled?

- Yes, fiberglass mat tissue can be recycled. It is a common practice to recycle fiberglass waste, including fiberglass mat tissue, by breaking it down into smaller fibers and using it as a raw material in various industries such as insulation, construction, and automotive. Recycling fiberglass helps to reduce waste and conserves resources.

Send your message to us

Fiberglass Mat Tissue Glass Wool Heat Insulation, Sound Proof, and Fireproof Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords