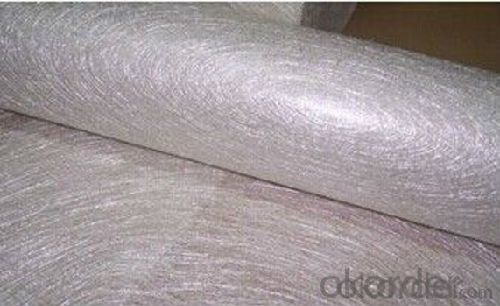

Fiberglass Mat Tissue - Fiberglass Stitched Mat 300g 150~2600mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description & application | ||||||||||||||||||||||||

◎ The stitched mat is made of chopped strand which randomly dispersed and be stitched together by polyester thread. The width is available from 150-2400mm.Density of mat generally is 300-600g/m2.

| ||||||||||||||||||||||||

| ||||||||||||||||||||||||

◎ Uniform thickness, good wet tensile strength retention. ◎ Excellent mechanical properties. | ||||||||||||||||||||||||

| ||||||||||||||||||||||||

| ||||||||||||||||||||||||

| ||||||||||||||||||||||||

Each roll is wrapped by PE film and then packed into carton. Stacking in bulk or palletized is available, the pallet shall be no higher than 2 layers.

|

FAQ

1) Which delivery term will you usually offer?

We usually offer FOB Chongqing, FOB Shenzhen, FOB Shanghai or CIF port (defined by the customer).

2) What are the specialties on your company?

We specialized in Reliable quality material, good technical guidance, and full range of products (from High end to off – grade quality materials and cover most of glass fiber products) in order to meet different customer’s requirements. We have close contact with major glass fiber manufacturers in China that can save you too much time.

- Q: Can fiberglass mat tissue be used for creating molds?

- No, fiberglass mat tissue is typically not used for creating molds. It is more commonly used for reinforcing fiberglass laminates and composites.

- Q: How does fiberglass mat tissue compare to other insulation materials?

- Fiberglass mat tissue, as an insulation material, offers numerous advantages over its counterparts. Primarily, it possesses exceptional thermal insulation properties, effectively preventing the transfer of heat and maintaining indoor temperatures at a comfortable level. This quality is particularly significant in extreme climates, where the building envelope may be susceptible to extreme cold or heat. Furthermore, fiberglass mat tissue exhibits resistance to moisture, mold, and mildew, which contributes to its longevity and durability as an insulation option. Its inability to absorb water prevents the growth of mold and the deterioration of the material over time. This attribute proves especially advantageous in areas with high humidity or a propensity for moisture accumulation, such as basements or bathrooms. In addition, fiberglass mat tissue is non-combustible and possesses a high fire resistance rating. Consequently, it serves as a safe choice for insulation, limiting the spread of flames in the event of a fire. It also acts as a barrier, impeding the fire from extending to other sections of the building and granting occupants valuable time for evacuation. Regarding installation, fiberglass mat tissue is relatively easy to handle and install. It can be conveniently cut to fit any desired shape or size, allowing for flexibility during the installation process. Its versatility is further evident in its applicability to walls, floors, ceilings, and roofs. Lastly, fiberglass mat tissue stands as an environmentally friendly option. It is manufactured from recycled glass and sand, reducing waste and conserving precious natural resources. Moreover, it remains recyclable at the conclusion of its lifespan, further minimizing its environmental impact. Overall, the exceptional thermal insulation properties, durability, moisture and fire resistance, ease of installation, and environmental sustainability of fiberglass mat tissue position it as a highly favorable choice in comparison to alternative insulation materials.

- Q: Is fiberglass mat tissue suitable for underground applications?

- Yes, fiberglass mat tissue is suitable for underground applications. It is commonly used in underground construction projects due to its excellent strength, durability, and resistance to water and corrosion. Additionally, fiberglass mat tissue provides insulation and reinforcement, making it ideal for underground applications such as tunnels, basements, and pipelines.

- Q: How is fiberglass mat tissue made?

- The production of fiberglass mat tissue involves a wet-laid process, which encompasses several sequential steps. Initially, glass fibers are generated by melting and extruding glass through tiny apertures, resulting in continuous filaments. These filaments are subsequently coated with a sizing agent, enhancing their manipulability and fortifying the end product. Subsequently, the glass fibers are fragmented into shorter lengths to create a fiber mat. This operation is typically accomplished using either a knife or a rotary chopper. The fragmented fibers are then amassed and fashioned into a thin layer on a moving conveyor belt. Concurrently, a binder solution is formulated by blending a synthetic resin with water. This solution is then sprayed onto the fiber mat, ensuring the fibers become saturated and bonded together. The quantity of binder utilized determines the strength and flexibility of the final product. To guarantee the even distribution of the binder and the proper consolidation of the mat, it is passed through a sequence of rollers. These rollers exert pressure, eliminating excess water, compacting the fibers, and fostering adhesion among them. Once the mat is consolidated and attains the desired thickness, it undergoes a drying process, either in an oven or via hot air currents. This eliminates any remaining moisture and solidifies the binder, transforming it into a solid resin. Following the drying stage, the fiberglass mat tissue is wound onto rolls for storage or further processing. Due to its exceptional strength, resistance to corrosion, and thermal insulation properties, it serves as a reinforcement material in diverse industries such as construction, automotive, and aerospace.

- Q: How does fiberglass mat tissue compare to other types of insulation materials?

- Fiberglass mat tissue offers several advantages over other types of insulation materials. Firstly, it has excellent thermal insulation properties, making it highly effective in reducing heat transfer and maintaining a comfortable indoor environment. Additionally, fiberglass mat tissue is lightweight, easy to handle, and can be easily installed in various applications, such as walls, roofs, and floors. It is also resistant to moisture, mold, and pests, ensuring long-lasting performance and durability. Moreover, fiberglass mat tissue is cost-effective and provides great value for money due to its high efficiency and low maintenance requirements. Overall, fiberglass mat tissue stands out as a reliable and efficient insulation material in comparison to others available in the market.

- Q: Is fiberglass mat tissue suitable for insulation in high-rise buildings?

- High-rise buildings can benefit from the suitability of fiberglass mat tissue for insulation. This widely used material possesses exceptional thermal and acoustic properties, making it an ideal choice. Its lightweight and flexible nature, along with easy installation, ensure efficiency and effectiveness in high-rise structures. Furthermore, fiberglass mat tissue boasts excellent fire resistance, a crucial requirement for multi-story buildings. It also resists moisture, mold, and pests, ensuring durability and optimal performance. Customization for walls, floors, and ceilings allows consistent insulation throughout the entire building. In conclusion, fiberglass mat tissue is a dependable and cost-effective insulation solution for high-rise buildings.

- Q: Does fiberglass mat tissue provide any UV resistance?

- Yes, fiberglass mat tissue typically provides some level of UV resistance. The fiberglass mat tissue is made up of glass fibers that are embedded in a matrix of resin. These fibers and resin provide some degree of protection against UV radiation from the sun. However, it is important to note that the level of UV resistance may vary depending on the specific composition and manufacturing process of the fiberglass mat tissue. Additionally, prolonged exposure to UV radiation can still cause some degradation over time, so it is recommended to take appropriate measures such as using UV-resistant coatings or finishes to enhance the durability and lifespan of the fiberglass mat tissue in outdoor applications.

- Q: Can fiberglass mat tissue be used for repairing fiberglass jet skis?

- Yes, fiberglass mat tissue can be used for repairing fiberglass jet skis. Fiberglass mat tissue is commonly used in fiberglass repairs as it provides strength and reinforcement to the damaged area. It is a versatile material that can be used for various fiberglass repair applications, including repairing cracks or holes in jet skis. When applied properly, fiberglass mat tissue can help restore the structural integrity of the jet ski and ensure a durable and long-lasting repair.

- Q: How does fiberglass mat tissue compare to other reinforcing materials, such as carbon fiber or kevlar?

- Fiberglass mat tissue, carbon fiber, and Kevlar are all reinforcing materials commonly used in various industries for their high strength and durability. However, they differ in their composition and properties, leading to different applications and performance characteristics. Fiberglass mat tissue is made from fine glass fibers randomly oriented and bonded together with a binder. It offers excellent tensile strength, corrosion resistance, and low cost, making it widely used in construction, automotive, and marine industries. Fiberglass mat tissue is also highly flexible, allowing it to conform to complex shapes easily. However, it may not have the same strength-to-weight ratio as carbon fiber or Kevlar. Carbon fiber is composed of thin strands of carbon atoms tightly woven together, resulting in an extremely strong and lightweight material. It has a higher tensile strength than fiberglass mat tissue, making it suitable for applications where weight reduction and high strength are critical, such as aerospace, sports equipment, and automotive components. Carbon fiber also has excellent stiffness and fatigue resistance, but it is more expensive compared to fiberglass mat tissue. Kevlar, on the other hand, is an aramid fiber known for its exceptional strength-to-weight ratio and resistance to impact and abrasion. It is often used in applications where high impact resistance is required, such as bulletproof vests, helmets, and protective clothing. While Kevlar is stronger than fiberglass mat tissue, it is not as rigid as carbon fiber and may not offer the same level of stiffness. Kevlar is also more expensive than fiberglass mat tissue but less expensive than carbon fiber. In summary, fiberglass mat tissue, carbon fiber, and Kevlar each have their own unique characteristics and advantages. Fiberglass mat tissue is versatile, cost-effective, and flexible, while carbon fiber offers exceptional strength and stiffness. Kevlar excels in impact resistance and durability. The choice of reinforcing material depends on the specific application requirements, cost considerations, and desired performance characteristics.

- Q: Can fiberglass mat tissue be used for making lightweight furniture?

- Yes, fiberglass mat tissue can be used for making lightweight furniture. Fiberglass mat tissue is a thin, lightweight material made from glass fibers that are bonded together with a resin. It is commonly used in various industries, including automotive, aerospace, and construction, for its excellent strength-to-weight ratio. When used in furniture manufacturing, fiberglass mat tissue can be layered and molded into different shapes and forms, providing structural support and rigidity while keeping the overall weight of the furniture low. This makes it an ideal choice for creating lightweight furniture pieces that are easy to move around and transport. Additionally, fiberglass mat tissue is highly durable and resistant to moisture, chemicals, and heat, making it suitable for both indoor and outdoor furniture applications. Its versatility allows furniture designers and manufacturers to create unique and innovative designs while maintaining the desired lightweight characteristics. However, it is important to note that the final product's quality and performance will also depend on the overall design, construction, and other materials used in combination with the fiberglass mat tissue. Therefore, proper engineering and manufacturing techniques should be employed to ensure the furniture's longevity, stability, and safety.

Send your message to us

Fiberglass Mat Tissue - Fiberglass Stitched Mat 300g 150~2600mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords