Fiberglass Mat Tissue - E-Glass Fiberglass Type Jushi Fiberglass Chopped Strand Mat

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

E-Glass Fiberglass Type Jushi Fiberglass Chopped Strand Mat

Introduction:

Chopped Strand Mat is characterized by good combination of resin, easy operation, good wet strength retention, good laminate transparency and low cost. It is suitable for the application by hand lay-up FRP moldings, such as, various sheets and panels, boat hulls, boat tubs, cooling towers, corrosion resistant, vehicles, etc.

Function:

Fiberglass chopped strand mat is chopped using the "E" chopped glass and emulsion adhesive bond. It is suitable for hand lay and can enhance the unsaturaed ployester resins.

Product Features:

Consistent thickness and stiffness;

Rapid impregnating and good compatibility with resin;

Superior wet through with less air trap;

Good mechanical properties and high strength of parts.

Superior acid corrosion resistance

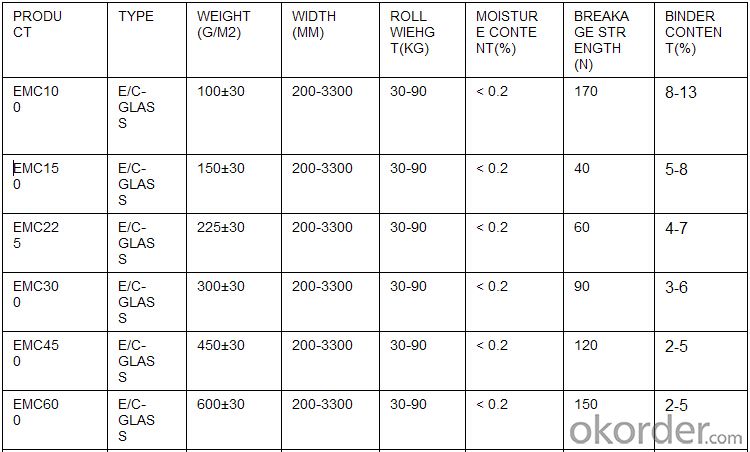

Technical Data:

Packaging:

Product is manufactured in form of a roll wrap on a paper tube then after packed in a plastic bag and placed in a cardboard carton. Rolls can be loaded in a container directly or on pallets.

Deposited:

Chopped Strand Mat should be stored in dry, cool, clean and rainproof area. Recommended temperature range of storage is between 15-30 and relative humidity between 40%-70%.

FAQ:

Is sample available ?

Yes, we provide the free samples, but customers themselves need pay the shipping fee

What's your MOQ?

Our MOQ is one 1*20' full container loading

How do you pack the fiberglass

(1) First, the mat is in roll packed in White PE fIlm.

(2) Then the rolls packed in the carton

4.Which knid of payment terms can you accept?

We can accept 30% prepayment, 70% payment before shippment. LC is also accepted

- Q: Can fiberglass mat tissue be used for insulation in underground pipelines?

- Indeed, insulation in underground pipelines can be achieved using fiberglass mat tissue. Renowned for its outstanding thermal insulation characteristics, fiberglass mat tissue is widely employed across diverse industrial sectors, including underground pipeline installations. By impeding heat transfer between the pipeline and its surroundings, it effectively sustains the desired temperature within the pipeline, thereby providing insulation. Furthermore, fiberglass mat tissue exhibits resistance against moisture, chemicals, and corrosion, rendering it an optimal selection for underground scenarios where pipelines face harsh conditions. Consequently, fiberglass mat tissue emerges as a dependable and efficacious insulation material for underground pipelines.

- Q: What is the moisture resistance of fiberglass mat tissue?

- The moisture resistance of fiberglass mat tissue is generally quite high. The material is typically made from fiberglass strands that are tightly woven together, creating a dense and water-resistant surface. This makes it highly effective in applications where moisture exposure is common, such as in the construction industry for roofing, insulation, and waterproofing purposes. Additionally, fiberglass mat tissue is often treated with special coatings or additives that further enhance its moisture resistance, making it even more durable and reliable in wet or humid environments. Overall, the moisture resistance of fiberglass mat tissue is a significant advantage and contributes to its widespread use in various industries.

- Q: Can fiberglass mat tissue be used in high-temperature applications?

- No, fiberglass mat tissue cannot be used in high-temperature applications.

- Q: What is the expected lifespan of fiberglass mat tissue in underground applications?

- Different factors can affect the expected lifespan of fiberglass mat tissue in underground applications. These factors include the conditions of the underground environment, the quality and thickness of the fiberglass mat tissue, and the level of maintenance and care provided. On average, fiberglass mat tissue is known for its durability and longevity, which makes it suitable for use underground. Generally, fiberglass mat tissue is designed to resist corrosion, moisture, and other environmental elements commonly found in underground settings. This makes it a reliable choice for protecting underground pipes, tanks, and other infrastructure from deterioration. When installed correctly and maintained regularly, fiberglass mat tissue can last 50 years or more in underground applications. However, it is important to note that this estimate can vary depending on the specific conditions and usage of the fiberglass mat tissue. To maximize the lifespan of fiberglass mat tissue in underground applications, it is recommended to follow industry best practices. These practices include using proper installation techniques, conducting regular inspections, and promptly addressing any cracks or damage. By following these steps, the lifespan of fiberglass mat tissue can be extended, ensuring long-term reliability and durability underground.

- Q: What is the expected lifespan of fiberglass mat tissue in residential applications?

- The expected lifespan of fiberglass mat tissue in residential applications can vary depending on various factors such as the quality of the material, the installation process, and the environmental conditions it is exposed to. However, on average, fiberglass mat tissues are designed to have a lifespan of around 20 to 30 years. Fiberglass mat tissues are commonly used in residential applications for reinforcing and strengthening purposes, particularly in areas prone to moisture and water damage such as bathrooms, kitchens, and basements. They are known for their excellent resistance to mold, mildew, and rot, making them a popular choice in these areas. With proper installation and maintenance, fiberglass mat tissues can provide long-lasting support and protection to the underlying surfaces. However, it is important to note that they can be susceptible to damage if not handled or installed correctly. Any improper installation or exposure to extreme conditions such as excessive heat or direct sunlight can significantly reduce their lifespan. Regular inspection and maintenance of fiberglass mat tissues are essential to ensure their optimal performance and longevity. This may include checking for any signs of wear, tear, or water damage, and promptly addressing any issues that arise. Additionally, periodic cleaning and sealing can help prolong the lifespan of the material. In summary, while the expected lifespan of fiberglass mat tissue in residential applications is typically around 20 to 30 years, it is crucial to consider factors such as quality, installation, and maintenance to ensure its durability and longevity.

- Q: How does the strength of fiberglass mat tissue compare to other reinforcement materials?

- In comparison to other reinforcement materials, such as steel or carbon fiber, fiberglass mat tissue possesses a considerable level of strength. Comprised of an intricate arrangement of numerous glass fibers, this material proves to be robust and durable. Commonly employed in applications necessitating great strength, such as the construction industry for bolstering concrete structures, the automotive sector for manufacturing lightweight yet sturdy components, and the aerospace industry for constructing aircraft parts. Fiberglass mat tissue presents several advantages when contrasted with other reinforcement materials. Firstly, it exhibits a relatively low weight, rendering it more manageable and easier to transport. Furthermore, it boasts a high tensile strength, enabling it to endure stretching or pulling forces without succumbing to breakage. It also showcases impressive impact resistance and possesses the ability to absorb energy, making it suitable for contexts where impact resistance plays a crucial role. Moreover, fiberglass mat tissue demonstrates exceptional resistance to corrosion, making it suitable for deployment in harsh environments or in contact with chemicals. Unlike steel, it does not rust or deteriorate over time. Additionally, fiberglass mat tissue is non-conductive, a quality that proves useful in scenarios where electrical conductivity could pose a safety hazard or interfere with electronic equipment. In conclusion, fiberglass mat tissue's strength is regarded as exceptional when compared to other reinforcement materials. Its high tensile strength, lightweight composition, corrosion resistance, and impact resistance render it a versatile and widely utilized substance across various industries.

- Q: Is fiberglass mat tissue fire resistant?

- Yes, fiberglass mat tissue is fire resistant.

- Q: What are the recommended storage and handling practices for fiberglass mat tissue?

- The recommended storage and handling practices for fiberglass mat tissue include keeping it in a dry and well-ventilated area, away from direct sunlight or heat sources. It should be stored horizontally on a clean and level surface to prevent any damage or deformation. When handling, it is advisable to wear protective gloves and safety glasses to avoid any contact with the skin or eyes. Additionally, it is important to handle the material with care to prevent tearing or puncturing, and to avoid any exposure to moisture or chemicals that may degrade its quality.

- Q: What are the different grades of fiberglass mat tissue available?

- In the market, you can find various grades of fiberglass mat tissue. These grades differ in terms of their weight, thickness, and strength. The most popular grades include lightweight, medium-weight, and heavyweight fiberglass mat tissue. When it comes to lightweight fiberglass mat tissue, it is generally thinner and lighter compared to other grades. It is commonly used in situations where flexibility and easy handling are important. This grade is suitable for projects like laminating lightweight structures, making molds, and doing repairs. If you're looking for a versatile option that offers a balance between strength and flexibility, medium-weight fiberglass mat tissue is the way to go. It is widely used in boat building, automotive repairs, and general fiberglass reinforcement. This grade provides sufficient strength while still being manageable to work with. On the other hand, if you need superior strength and durability, heavyweight fiberglass mat tissue is the grade for you. It is the thickest and heaviest grade available in the market. This grade is perfect for applications that require high structural integrity, such as construction, aerospace, and marine industries. Apart from these standard grades, there may be variations and special grades available depending on the manufacturer and the specific requirements of your project. It is crucial to consult with a supplier or manufacturer to determine the most suitable grade of fiberglass mat tissue for your particular application.

- Q: What are the advantages of using fiberglass mat tissue in construction?

- There are several advantages to using fiberglass mat tissue in construction. Firstly, fiberglass mat tissue provides excellent reinforcement and strength to various construction materials. It enhances the structural integrity and durability of the final product, making it resistant to cracks, impacts, and weathering. This makes fiberglass mat tissue an ideal choice for reinforcing concrete, roofing materials, and composite products. Secondly, fiberglass mat tissue is lightweight and easy to handle, making it convenient to work with during construction. Unlike traditional reinforcement materials like steel, which can be heavy and require specialized tools for installation, fiberglass mat tissue is easily cut, shaped, and applied. This reduces the labor and time required for construction, leading to cost savings. Additionally, fiberglass mat tissue is non-corrosive and non-conductive, making it suitable for use in a wide range of environments. It does not rust or degrade over time, even in harsh conditions, ensuring the longevity and reliability of the construction. Moreover, fiberglass mat tissue does not conduct electricity, making it a safe choice for applications where electrical conductivity needs to be avoided. Furthermore, fiberglass mat tissue offers excellent thermal insulation properties. It acts as a barrier to heat transfer, helping to maintain a comfortable and energy-efficient interior environment. This can lead to reduced heating and cooling costs in buildings, making fiberglass mat tissue a sustainable and cost-effective option. Lastly, fiberglass mat tissue is resistant to fire and chemicals. It does not burn or release toxic fumes when exposed to flames, providing an added level of safety in construction. Additionally, it is resistant to many chemicals, including acids and alkalis, making it suitable for use in corrosive environments such as chemical plants or industrial facilities. Overall, the advantages of using fiberglass mat tissue in construction include enhanced reinforcement, lightweight and easy handling, non-corrosive and non-conductive properties, thermal insulation, fire resistance, and chemical resistance. These benefits make it a versatile and reliable material for various construction applications.

Send your message to us

Fiberglass Mat Tissue - E-Glass Fiberglass Type Jushi Fiberglass Chopped Strand Mat

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords