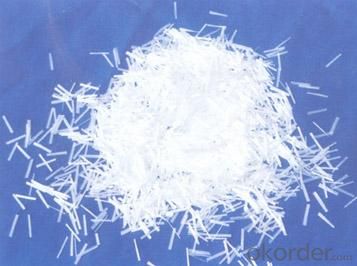

Fiberglass Mat Tissue Chopped Strands for Thermoplastic

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 1000000Kg Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

Chopped Stands for Thermoplastic are based on silane coupling agent and special sizing formulation, compatible with PA,PBT/PET, PP, AS/ABS, PC, PPS/PPO,POM, LCP;

2.Product Features

Extremely low resin demand, delivering low viscosity to BMC paste

High impact strength; High LOI rate

High strand stiffness; Compatible with rubber

3.Product Specifications

Property | Fibre diameter | Moisture Content | Size Content | Chop |

(%) | (%) | (%) | (%) | |

Mathods | IS01888 | ISO3344 | ISO1887 | |

3mm | ±10 | ≤3.0 | 0.1±0.05 | 98 |

6mm | ||||

9mm | ||||

12mm |

Special specification can be produce according to customer requirements.

4.FAQ

Packaging:

Each bag can be taken (15-25kgs). Could also take a big container bag.

Storage:

Unless otherwise specified, It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q: How is fiberglass mat tissue used in the manufacturing of wind turbine blades?

- Fiberglass mat tissue is used in the manufacturing of wind turbine blades as a reinforcement material. It is typically sandwiched between layers of resin to provide strength, stiffness, and durability to the blades. The mat tissue helps to distribute and absorb the loads and stresses experienced by the blades during operation, making them more resistant to fatigue and structural failure.

- Q: What is the cost of fiberglass mat tissue?

- The price of fiberglass mat tissue can fluctuate based on a variety of factors including the brand, quality, quantity, and location. Typically, the cost per square foot for fiberglass mat tissue falls between $0.50 and $2. However, it is crucial to consider that prices may vary depending on the project's specific requirements and the supplier or retailer from whom it is obtained. To ensure the best value and appropriateness for your needs, it is advisable to conduct thorough research and compare prices from different sources.

- Q: Can fiberglass mat tissue be used for pipe wrapping?

- Pipe wrapping can indeed utilize fiberglass mat tissue, a lightweight and flexible material extensively employed in reinforcing and safeguarding various structures, including pipes. The primary purpose of fiberglass mat tissue is to enhance the pipes' strength and durability, thereby rendering them more resilient to damage and corrosion. Wrapping the pipe with fiberglass mat tissue is a simple process that creates a protective layer, effectively preventing leaks and prolonging the pipe's lifespan. Moreover, fiberglass mat tissue is renowned for its remarkable insulation properties, contributing to the maintenance of the contents' temperature as they flow through the pipe. Consequently, fiberglass mat tissue serves as a suitable material for pipe wrapping and finds widespread application across diverse industries.

- Q: Is fiberglass mat tissue suitable for soundproofing?

- Fiberglass mat tissue can be suitable for soundproofing purposes, but its effectiveness may vary depending on the specific requirements and desired level of soundproofing. Fiberglass mat tissue is a lightweight and flexible material that can effectively absorb and dampen sound waves. It has good acoustic properties and can help reduce noise transmission, making it a viable option for soundproofing applications. However, it is important to note that fiberglass mat tissue alone may not provide sufficient soundproofing, especially in high-noise environments. For optimal results, it is recommended to combine it with other soundproofing materials such as acoustic foam panels or mass-loaded vinyl to enhance its soundproofing capabilities. Additionally, the thickness and density of the fiberglass mat tissue can also affect its sound absorption properties. Thicker and denser mats are generally more effective at attenuating sound waves, but they may also be less flexible and harder to install. In conclusion, while fiberglass mat tissue can contribute to soundproofing efforts, its suitability depends on the specific requirements, desired level of soundproofing, and the use of additional materials. Consulting with a soundproofing expert or conducting thorough research on the specific application is recommended to determine the most appropriate solution for effective soundproofing.

- Q: Can fiberglass mat tissue be used for making swimming pool shells?

- Yes, fiberglass mat tissue can be used for making swimming pool shells.

- Q: Is fiberglass mat tissue suitable for insulation in residential buildings?

- Yes, fiberglass mat tissue is suitable for insulation in residential buildings. It is a widely used and effective insulation material that offers excellent thermal performance, soundproofing capabilities, and fire resistance. Additionally, it is easy to install, durable, and does not degrade over time.

- Q: Does fiberglass mat tissue require any special handling or storage requirements?

- Yes, fiberglass mat tissue does require some special handling and storage requirements. Firstly, it is important to handle fiberglass mat tissue with care to avoid any damage or breakage. The tissue should be handled gently and not dragged or dropped, as this can cause the fibers to separate or become damaged. It is also recommended to wear gloves and protective clothing when handling fiberglass mat tissue to prevent any skin irritation or injuries. In terms of storage, fiberglass mat tissue should be kept in a clean and dry environment. It is crucial to protect it from moisture, as exposure to water can weaken the fibers and reduce its effectiveness. Therefore, it is best to store fiberglass mat tissue in a sealed, moisture-proof packaging or in a dry room with controlled humidity levels. Additionally, it is important to keep fiberglass mat tissue away from direct sunlight or extreme temperatures. Exposure to high temperatures can cause the resin in the tissue to cure prematurely, while excessive cold can make it brittle and more prone to damage. Therefore, it is recommended to store fiberglass mat tissue in a cool, shaded area to maintain its quality and ensure its longevity. By following these special handling and storage requirements, fiberglass mat tissue can be protected and preserved in its optimal condition, ready for use in various applications such as construction, insulation, or automotive industries.

- Q: Can fiberglass mat tissue be recycled?

- Yes, fiberglass mat tissue can be recycled. Fiberglass is made from a combination of glass fibers and resin, and both components can be reused. The recycling process involves separating the glass fibers from the resin, often through a mechanical grinding or melting process. The separated fibers can then be used to make new fiberglass products, such as insulation, roofing materials, or even new fiberglass mat tissue. Recycling fiberglass helps to reduce the environmental impact of this material by diverting it from landfills and conserving resources. However, it is worth noting that the recycling process can be complex and costly, so not all recycling facilities may accept fiberglass mat tissue.

- Q: Can fiberglass mat tissue be used for insulation in cleanrooms?

- Yes, fiberglass mat tissue can be used for insulation in cleanrooms. It is a commonly used material due to its excellent thermal insulation properties, low cost, and high resistance to chemicals and moisture. Additionally, fiberglass mat tissue has low particulate emission, making it suitable for cleanroom environments where maintaining a controlled and sterile atmosphere is crucial.

- Q: Is fiberglass mat tissue suitable for automotive applications?

- Yes, fiberglass mat tissue is suitable for automotive applications. Fiberglass mat tissue is a versatile material that offers numerous benefits when used in automotive applications. It provides excellent strength and durability, which is essential for automotive parts that need to withstand harsh conditions and heavy usage. Fiberglass mat tissue also has good thermal and electrical insulation properties, making it suitable for applications where temperature resistance and electrical insulation are required. Additionally, fiberglass mat tissue is lightweight, which can help improve fuel efficiency and overall vehicle performance. It is also easy to mold and shape, allowing manufacturers to create complex automotive parts with precision. Furthermore, fiberglass mat tissue is resistant to corrosion, chemicals, and UV radiation, ensuring the longevity and reliability of automotive components. Overall, the unique properties of fiberglass mat tissue make it an ideal choice for various automotive applications, including but not limited to body panels, interior components, structural reinforcements, and sound insulation. Its strength, durability, insulation properties, lightweight nature, and resistance to corrosion and chemicals make it a reliable and cost-effective material for the automotive industry.

Send your message to us

Fiberglass Mat Tissue Chopped Strands for Thermoplastic

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 1000000Kg Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords