Hanes Geogrids Fiberglass with Bitumen Coated for Wholesale

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

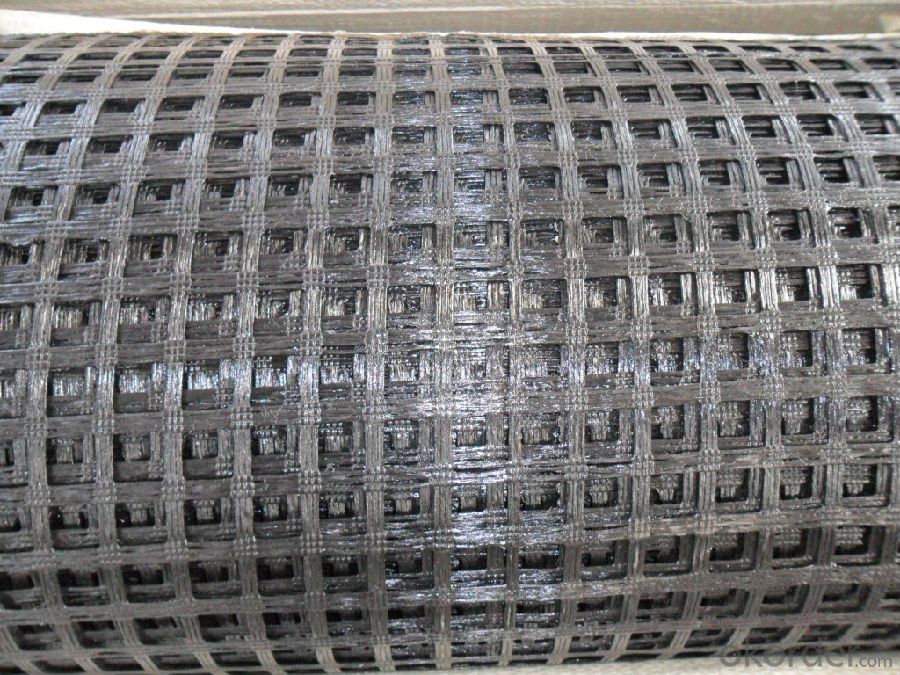

Fiberglass Geogrid with Bitumen Coated for Wholesale

Description Of Fiberglass Geogrid with Bitumen Coated for Wholesale:

Fiberglass geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed. This product is made by weaving and covering fiberglass filament. It is featured by high vertical and horizontal tensile strength, low unit extension, high flexibility, and favorable high and low temperature resistance. The products after surface covering own the favorable property of alkali resistance and aging resistance.

Main Features of Fiberglass Geogrid with Bitumen Coated for Wholesale:

1.High tensile strength, low elongation.

2.No long-term creep: the product can keep for a long time performance.

3.Thermal stability: fiber glass melting temperature above 1000 ℃.

4.The compatibility with asphalt.

5.Physical and chemical stability.

Specifications of Fiberglass Geogrid with Bitumen Coated for Wholesale:

Tensile Strength (KN) | Warp | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >200 |

Weft | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >120 | |

Elongation(%) | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | |

Mesh Size(mm) | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | |

Elastic Modulus | 76 | 76 | 76 | 76 | 76 | 76 | 76 | 76 | |

Width(m) | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | |

Length(m) | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | |

Temperature Resistant(℃) | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | |

Resin Content (%) | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | |

Glue Type | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | |

Applications of Fiberglass Geogrid with Bitumen Coated for Wholesale:

Strengthen bitumen concrete roadway and reduce and prevent various kinds of reflection gaps on roadway.

1.Suitable for highway, railway, airport road of subgrade enhancement.

2.Suitable for the large parking lot and port freight yard that the foundations of the permanent load increased.

3.Suitable for railway, highway slope protection.

4.Suitable for culverts.

5.Suitable for the uniaxial tensile geogrid reinforced soil secondary enhancement, after further enhance soil, prevent soil erosion.

6.Mining, tunnel reinforcement.

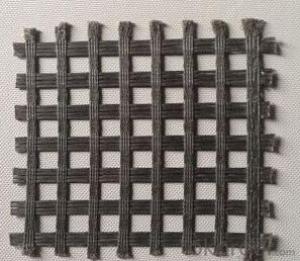

IMages of Fiberglass Geogrid with Bitumen Coated for Wholesale:

FAQ of Fiberglass Geogrid with Bitumen Coated for Wholesale:

1. What are we supplying?

We are specialized in producing Geosynthetic materials, like Geogrid Series, HDPE Geocell, Geonet, Geotextile, Geomat, Tri Denmensional Composite Grainage Geonet, and Geomembrane Series.

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: What is the effect of geogrid aperture size on performance?

- The effect of geogrid aperture size on performance is that a smaller aperture size typically leads to better performance. A smaller aperture size allows for better soil confinement and interlock, resulting in improved load distribution and higher tensile strength. This enhanced performance helps to prevent soil erosion, increase stability, and enhance the overall durability of geogrid structures.

- Q: Can geogrids be used in pond liners?

- Yes, geogrids can be used in pond liners. Geogrids are often used as a reinforcement material in the construction of pond liners to enhance their stability, prevent soil erosion, and increase their overall strength and durability.

- Q: Peel force mainly in the size of raw materials

- Depends on the strength of the welding point

- Q: What are the types of Geogrid

- Glass fiber geogrid, 1595341 polyester fiber geogrid, glass fiber, polyester composite geotextile, steel plastic composite geogrid, PP grid, one-way two-way stretching plastic geogrid,

- Q: How do geogrids improve the performance of geotextile erosion control blankets?

- Geogrids improve the performance of geotextile erosion control blankets by providing additional reinforcement and stability to the blanket. They help distribute loads more evenly, prevent soil erosion, and enhance the overall strength and durability of the erosion control system.

- Q: What is the GDL geogrid

- GDL geogrid is uniaxial plastic geogrid, uniaxial plastic geogrid with high density polyethylene (HDPE) as raw materials, pressure into a sheet by extrusion and punching network rules, and then the longitudinal stretch into the geogrid.

- Q: Geogrid price? Solution!

- Geogrid is a kind of main geosynthetics, which has unique properties and effects compared with other geosynthetics. Geogrid is often used as reinforcement of reinforced soil structure or composite material. Geogrid is divided into four categories: plastic geogrid, steel plastic geogrid, fiberglass geogrid and fiberglass polyester geogrid.

- Q: Can geogrids be used in soil erosion control for agriculture?

- Yes, geogrids can be used in soil erosion control for agriculture. Geogrids are commonly used to reinforce and stabilize soil, preventing erosion caused by water runoff or wind. They provide strength and stability to the soil, reducing the risk of erosion and preserving the integrity of agricultural land.

- Q: How do geogrids enhance the performance of geocell confinement systems?

- Geogrids enhance the performance of geocell confinement systems by providing additional strength, stability, and load distribution. They reinforce the geocell walls, preventing lateral spreading and improving the overall structural integrity. Geogrids also enhance the load-bearing capacity of the geocell by evenly distributing the applied loads, reducing localized stresses, and preventing deformation or failure. Additionally, geogrids increase the overall stiffness of the geocell system, allowing for better confinement and improved performance in various applications such as slope stabilization, erosion control, and pavement reinforcement.

- Q: Can geogrids be used in stabilization of river training structures?

- Yes, geogrids can be used in the stabilization of river training structures. Geogrids are commonly used to reinforce and stabilize soil, and they can be particularly effective in river training structures where erosion and sedimentation are common challenges. By providing additional structural support, geogrids can help prevent soil displacement, increase stability, and enhance the overall performance and longevity of these structures.

Send your message to us

Hanes Geogrids Fiberglass with Bitumen Coated for Wholesale

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords