Fiberglass Facing e-glass Chopped Strand Mat Factory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

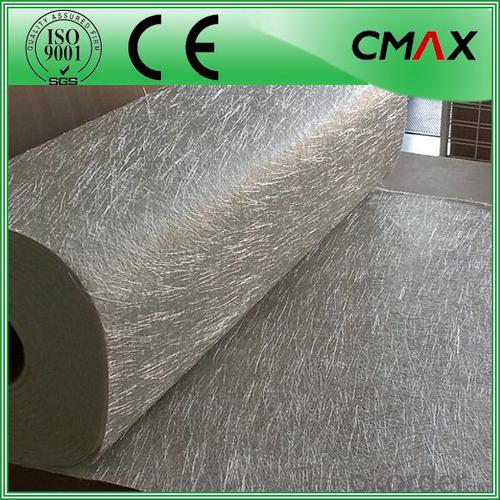

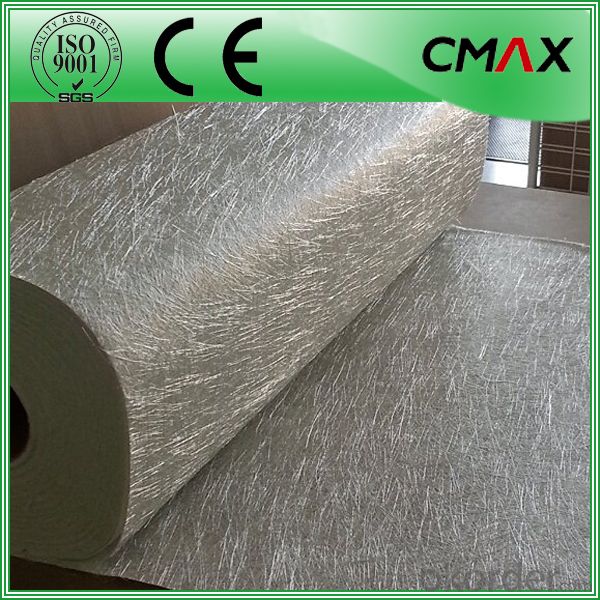

E-glass Fiberglass Chopped Strand Mat Factory

Introduction:

Fiberglass chopped strand mat is a non-woven E-or C-glassfiber mat, product manufactured by spreading continuous filament roving of 50mm in length randomly and uniformly in combination with polyester binder in powder form (or other binder in emulsion from). This product is characterized by good combination of resin, easy operation, good wet strength retention, good laminate transparency and low cost. It is suitable for the applications of hand lay-up FRP moldings, such as various sheets and panels, boat hulls, bath tubs, cooling towers, corrosion resistant, vehicles etc.

Function:

Fiberglass chopped strand mat is chopped using the "E" chopped glass and emulsion adhesive bond. It is suitable for hand lay and can enhance the unsaturaed ployester resins.

Technical Data:

| PRODUCT | TYPE | WEIGHT (G/M2) | WIDTH(MM) | ROLL WIEHGT (KG) | MOISTURE CONTENT(%) | BREAKAGE STRENGTH (N) | BINDER CONTENT(%) |

| EMC100 | E/C-GLASS | 100±30 | 200-3300 | 30-90 | < 0.2 | 170 | 8-13 |

| EMC150 | E/C-GLASS | 150±30 | 200-3300 | 30-90 | < 0.2 | 40 | 5-8 |

| EMC225 | E/C-GLASS | 225±30 | 200-3300 | 30-90 | < 0.2 | 60 | 4-7 |

| EMC300 | E/C-GLASS | 300±30 | 200-3300 | 30-90 | < 0.2 | 90 | 3-6 |

| EMC450 | E/C-GLASS | 450±30 | 200-3300 | 30-90 | < 0.2 | 120 | 2-5 |

| EMC600 | E/C-GLASS | 600±30 | 200-3300 | 30-90 | < 0.2 | 150 | 2-5 |

| EMC900 | E/C-GLASS | 900±30 | 200-3300 | 30-90 | < 0.2 | 180 | 2-5 |

Products Shows:

Certificates:

- Q: This question asks for methods to clean and maintain a piece of black fiberglass tape to ensure its longevity and functionality.

- <p>To clean and maintain a piece of black fiberglass tape, first, remove any loose dirt or debris with a soft brush. Avoid using abrasive materials that could scratch the surface. For stubborn dirt, use a mild soap solution and a soft cloth to gently clean the tape. Rinse thoroughly with clean water and allow it to dry completely. To prevent dirt buildup, regularly wipe the tape with a dry cloth. Store the tape in a cool, dry place away from direct sunlight to prevent fading and degradation. Avoid using harsh chemicals or solvents as they can damage the tape. Regular inspection for any signs of wear or damage is also recommended to ensure the tape remains in good condition.</p>

- Q: Is it permissible to use a personal brand of black fiberglass tissues for residential or commercial purposes?

- <p>Yes, you can use your own brand of black fiberglass tissues in your home or business. However, it's crucial to ensure that the product meets safety and quality standards. Check for certifications like ISO or ASTM to guarantee compliance with industry standards. Always follow the manufacturer's guidelines for installation and usage to maintain safety and effectiveness.</p>

- Q: What are the benefits of using fiberglass facing?

- Fiberglass facing offers numerous advantages in various applications. Firstly, its exceptional strength and durability make it highly resistant to cracking, warping, and other forms of damage. This quality makes it ideal for construction and structural purposes, where strength and longevity are crucial. Furthermore, fiberglass facing provides excellent thermal insulation properties. With its low thermal conductivity, it effectively prevents heat transfer and maintains a consistent temperature in both hot and cold environments. Consequently, it is widely used in insulation for buildings, HVAC systems, and other energy-efficient applications. Another benefit of fiberglass facing is its resistance to moisture and corrosion. Since it is non-porous and does not absorb water, it is highly resistant to mold, mildew, and rot. This makes it a suitable choice for damp or humid environments, including bathrooms and kitchens. Moreover, fiberglass facing is lightweight and easy to handle, making it convenient to install and transport. It can be easily cut and shaped to fit various surfaces and configurations, allowing for flexibility in design and installation. Its lightweight nature also reduces strain on supporting structures, making it cost-effective for construction projects. Lastly, fiberglass facing comes in a wide range of sizes, thicknesses, and finishes, allowing customization to meet specific project requirements. It can be coated or laminated with different materials to enhance performance, such as adding a vapor barrier or reflective surface. This versatility makes it suitable for various applications across industries, from construction to transportation. In summary, the advantages of fiberglass facing include its strength and durability, thermal insulation properties, resistance to moisture and corrosion, lightweight nature, and customization options. These qualities make it a popular choice in industries where these characteristics are highly valued.

- Q: Is it possible to utilize black fiberglass tissue in the construction industry?

- <p>Yes, black fiberglass tissue, also known as black fiber-reinforced polymer (FRP), can be used in construction. It is valued for its high strength-to-weight ratio, corrosion resistance, and durability. Black fiberglass is often used in reinforcing concrete structures, as a component in composite materials, and for strengthening or repairing existing structures. It is also used in the creation of lightweight and strong building materials, such as rebar replacements and for cladding due to its resistance to harsh weather conditions.</p>

- Q: Is it safe to use black fiberglass tissues in a microwave oven?

- <p>No, you should not use black fiberglass tissues in a microwave oven. Black fiberglass can absorb microwaves and potentially cause sparks or a fire. It is recommended to use microwave-safe materials such as glass, ceramic, or microwave-safe plastic containers when heating food in a microwave. Always check the manufacturer's guidelines for the specific microwave-safe materials and avoid using anything that could be a fire hazard.</p>

- Q: This question asks about the impact of black fiberglass tissue on the quality of air inside buildings.

- <p>Black fiberglass tissue, commonly used as insulation, can affect indoor air quality if not properly installed or if it becomes damaged. Fiberglass releases tiny glass fibers into the air, which can be inhaled and cause respiratory irritation, allergies, or even more severe health issues over time. Proper installation and sealing can minimize the release of these fibers. Additionally, ensuring good ventilation in buildings can help reduce the concentration of airborne fibers. It's also important to follow safety guidelines when handling fiberglass to prevent exposure.</p>

- Q: Is it possible to utilize black fiberglass tissues for domestic cleaning purposes?

- <p>Black fiberglass tissues are not typically recommended for household cleaning tasks. Fiberglass, especially when in a loose or frayed state, can be abrasive and may scratch surfaces. It can also leave behind fibers that are difficult to remove. For cleaning, it's better to use materials specifically designed for the purpose, such as microfiber cloths, which are gentle on surfaces and effective at picking up dirt and dust without scratching.</p>

- Q: What are the uses of black fiberglass tissue in the construction industry?

- <p>Black fiberglass tissue, also known as black glass fiber cloth, is widely used in construction for its heat resistance, strength, and durability. It is commonly used as a reinforcement material in cementitious materials, such as in the production of GRC (Glass Reinforced Concrete) panels and other composite materials. It can also be used as a fire-resistant barrier in walls and ceilings, and for insulation purposes. Additionally, it is employed in the creation of lightweight and strong structures, such as in the construction of roofs and facades, due to its high tensile strength and low weight.</p>

- Q: This question asks about the cost of purchasing and installing black fiberglass tissue.

- <p>The cost of black fiberglass tissue can vary significantly based on several factors such as the quality, quantity, and the specific project requirements. On average, the material cost alone can range from $1 to $5 per square foot. Installation costs can add another $2 to $10 per square foot, depending on labor rates and complexity. For an accurate estimate, it's best to consult with a local supplier or contractor who can provide a quote tailored to your specific needs. Keep in mind that prices are subject to change and can differ by region and market conditions.</p>

- Q: Can fiberglass facing be used in high-temperature applications?

- No, fiberglass facing should not be used in high-temperature applications as it is not designed to withstand extreme heat and may melt or degrade.

Send your message to us

Fiberglass Facing e-glass Chopped Strand Mat Factory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords