Fiberglass Fabrics - High Quality Fiberglass Fabric Cloth

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 M2 m²

- Supply Capability:

- 50000000 M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

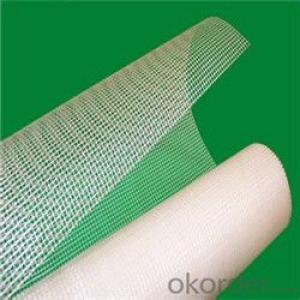

Introduction of Fiberglass Fabric Cloth:

Fiberglass fabric is weaved of high quality C-glass fibers or E-glass fibers.

Fiberglass fabric is a good construction material with the following excellent properties

* Dimensional stability

* High Strength

* Fire resistance, High heat resistance

* Good chemical resistance

* Durability

* Forms around complex surface shapes

Application of Fiberglass Fabric Cloth

Fiberglass fabrics can be used in a variety of applications, including construction in waterproofing applications for roofing and foundation, wall treatment, pipeline joint wrap.

Packing of Fiberglass Fabric Cloth:

Fiberglass fabric is wound on a paper tube with inner diameters of 50. 8, 76 or 152mm. Each roll is wrapped in a plastic bag, then to be packed in a carton box. The rolls are to be horizontally placed.

Width (cm): 90, 100, 127

Length (m): 100, 200, 300, 400

Storage of Fiberglass Fabric Cloth:

Store rolls in a cool, dry location

Protect rolls from weather and other damage.

- Q: What are the different weaves of fiberglass fabric?

- There are several different weaves of fiberglass fabric, including plain weave, twill weave, satin weave, leno weave, and basket weave.

- Q: Can fiberglass fabric be used for making protective sleeves and gloves?

- Protective sleeves and gloves can be made using fiberglass fabric, which is renowned for its outstanding resistance to heat, durability, and insulation properties. These attributes render it appropriate for tasks necessitating protection against elevated temperatures, sparks, and molten metal. The utilization of fiberglass fabric in the production of protective sleeves and gloves ensures a dependable shield against heat and flames. It can endure temperatures of up to 1000 degrees Fahrenheit, making it particularly well-suited for sectors like welding, foundries, and glass manufacturing. Moreover, fiberglass fabric boasts wear-resistance, tear-resistance, and excellent tensile strength, guaranteeing that the resulting protective sleeves and gloves are long-lasting and offer reliable protection. Furthermore, the fabric is lightweight and flexible, facilitating ease of movement and dexterity, which is crucial for tasks requiring fine motor skills. Nevertheless, it is worth noting that fiberglass fabric has the potential to cause skin irritation. Consequently, it is frequently coated or lined with other materials to prevent direct contact with the skin. This lining or coating not only enhances comfort but also provides supplementary protection against potential skin allergies or irritation. In conclusion, fiberglass fabric proves to be a suitable material for the production of protective sleeves and gloves due to its heat resistance, durability, and insulation properties. It offers dependable defense against high temperatures, sparks, and molten metal, making it an exceptional choice for individuals employed in industries exposed to heat and flame hazards.

- Q: What are the different fiberglass fabric weaves for impact resistance?

- There are several different fiberglass fabric weaves that are known for their impact resistance. Some of the common weaves include plain weave, twill weave, satin weave, and leno weave. Each weave has its own unique characteristics and advantages when it comes to providing impact resistance in fiberglass fabrics.

- Q: Can fiberglass fabric be used for gloves?

- Gloves can indeed utilize fiberglass fabric. This particular fabric is renowned for its exceptional durability and ability to withstand high temperatures, which makes it ideal for a wide range of industrial uses, including gloves. These gloves are commonly found in industries like manufacturing, automotive, and construction, where workers require protection against sharp objects, hot surfaces, and chemicals. To enhance their protective properties and provide comfort, the fiberglass fabric used in these gloves is typically coated or lined with a heat-resistant material. Nevertheless, it is crucial to be aware that some individuals may experience skin irritation or allergies when exposed to fiberglass fabric. In such cases, it is advisable to take proper precautions, such as wearing a liner glove or opting for gloves made from alternative materials.

- Q: How does fiberglass fabric perform in abrasive environments?

- Fiberglass fabric performs exceptionally well in abrasive environments due to its high strength, durability, and resistance to wear and tear. The fabric's unique composition of glass fibers provides excellent resistance against abrasion, ensuring its longevity and performance even in harsh conditions.

- Q: Can fiberglass fabrics be used for automotive applications?

- Certainly, automotive applications can indeed make use of fiberglass fabrics. Fiberglass fabrics possess notable characteristics such as high strength-to-weight ratio, durability, and resistance to heat and chemicals. These qualities render them appropriate for a variety of automotive uses like reinforcing body panels, constructing interior components, and creating structural reinforcements. By molding and shaping fiberglass fabrics, specific automotive parts can be easily accommodated, providing both strength and stability while simultaneously reducing weight. Moreover, the thermal insulation properties of fiberglass fabrics make them highly suitable for employment in automotive exhaust systems and engine compartments. All in all, fiberglass fabrics bring forth numerous advantages in terms of performance, durability, and design flexibility, thus proving their suitability for a wide array of automotive applications.

- Q: What is the difference between epoxy fiber glass cloth flooring and anticorrosive floor?

- Now the basic concrete curing terrace, do not believe you can do Baidu search, certainly want to do a little, you say is not.

- Q: Can fiberglass fabric be used for reinforcement in pharmaceutical tanks?

- Yes, fiberglass fabric can be used for reinforcement in pharmaceutical tanks. Fiberglass fabric is known for its high strength-to-weight ratio and excellent resistance to corrosion, chemicals, and extreme temperatures. These properties make it an ideal material for reinforcing tanks in the pharmaceutical industry, where the tanks may come into contact with various chemicals and substances. Fiberglass fabric can provide structural support, increase the durability and lifespan of the tanks, and ensure they meet the required safety standards. Additionally, fiberglass fabric is lightweight, making it easier to handle and install in tank applications. Overall, the use of fiberglass fabric for reinforcement in pharmaceutical tanks is a reliable and efficient choice.

- Q: What are the different laminating options available for fiberglass fabric?

- There are several laminating options available for fiberglass fabric, including epoxy, polyester, vinyl ester, and phenolic. Each option offers specific properties and benefits, such as improved strength, chemical resistance, and fire retardancy. The choice of laminating option depends on the intended application and desired performance characteristics.

- Q: What are the different fiberglass fabric weaves for flexibility?

- There are several different fiberglass fabric weaves that offer flexibility, including plain weave, twill weave, satin weave, and leno weave. These weaves provide varying degrees of flexibility and each has its own unique characteristics and uses.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 2002 |

| Annual Output Value | Below US$1 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Central America; Northern Europe; Southern Europe; South Asia |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | Above 10 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Design Service Offered; Buyer Label Offered |

| Product Price Range | High; Average |

Send your message to us

Fiberglass Fabrics - High Quality Fiberglass Fabric Cloth

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 M2 m²

- Supply Capability:

- 50000000 M2 Per Year m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords