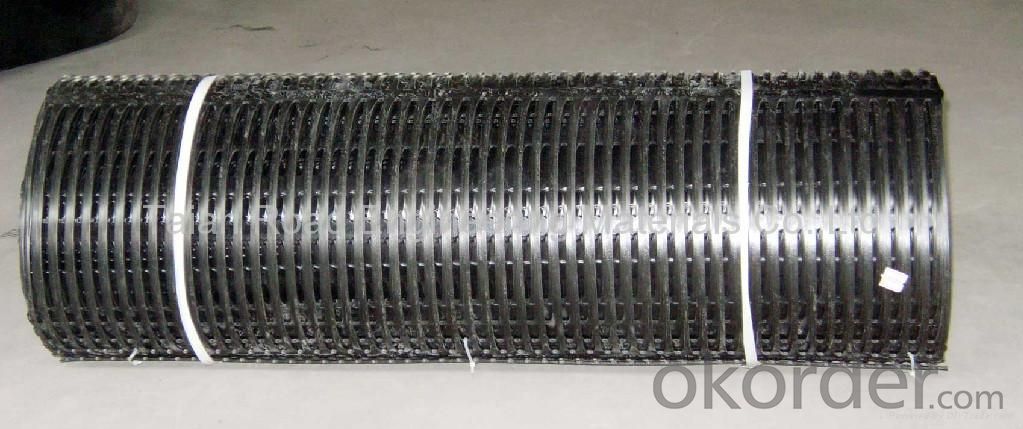

Fiberglass Fabrics from Malaysia Supplier - Fiberglass Geogrid for Airport Road Protection - Hot Sell

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

good thermal stability : the melting point of glass fibers is above 1000 °C , to ensure the stability of the glass fiber geogrids to withstand high temperature in a paving job .

Product has high strength, low elongation, high temperature, high modulus , light weight , good toughness, corrosion resistance , long life , etc. , can be widely used in the old concrete pavement , maintenance of airport runways , dams , river banks , while slope protection , road bridge , enhancement engineering field, to the road surface can be enhanced , reinforced to prevent pavement rutting fatigue crack , hot and cold telescopic cracks and reflection cracks below , and can the pavement load stress dispersion , extending pavement life .

2.Characteristics

The high tensile strength low - elongation : Fiberglass geogrid is a glass fiber , while the high tensile strength of glass fiber , more than other fibers and ordinary metals . Its high modulus , high resistance to deformation , elongation at break of less than 3% .

3.Application

Physical and chemical stability after special treatment agent coated handle , fiberglass geogrid to resist a variety of physical wear and chemical attack , but also to resist biological erosion and climate change to ensure that its performance is unaffected by the loss .

4.FAQ

3 No long-term creep : as a reinforcing material , with the ability to resist deformation under the load in the long-term creep resistance is extremely important, the glass fiber will not creep , to ensure that the products can long-term performance .

- Q: Is fiberglass fabric resistant to chemicals in water treatment facilities?

- Generally, chemicals found in water treatment facilities do not harm fiberglass fabric. Fiberglass is well-known for its ability to resist chemicals, meaning it can endure exposure to different substances without deteriorating or losing its structural integrity. This quality makes it perfect for use in water treatment facilities, where chemicals are crucial for disinfection, pH adjustment, and other treatment processes. Fiberglass fabric is capable of withstanding the corrosive effects of chlorine, acids, alkalis, and other commonly used chemicals in water treatment facilities. Moreover, fiberglass is non-reactive, which means it does not react with or contaminate the water being treated. This reliability and durability make fiberglass an excellent choice for water treatment applications.

- Q: How is fiberglass fabric repaired?

- Fiberglass fabric can be repaired by using a patching technique. The damaged area is typically cleaned and sanded, and then a suitable adhesive or epoxy resin is applied to attach a fiberglass patch onto the damaged section. The patch is then smoothed out and allowed to cure, ensuring a strong and seamless repair.

- Q: XHJ how about neoprene asphalt waterproof coating?

- With a brush (usually paint brush) stained with paint, in the construction of the roof evenly brushing, so that the thickness of uniform, not piled up, not flowing, no leakage brush.

- Q: Can fiberglass fabric be used for reinforcement in sports equipment?

- Yes, fiberglass fabric can be used for reinforcement in sports equipment. Fiberglass fabric is known for its high strength-to-weight ratio, making it an ideal material for reinforcing various sports equipment such as skis, snowboards, surfboards, and even tennis rackets. The fiberglass fabric is typically combined with a resin matrix to create a strong and durable composite material that can withstand the high stress and impact experienced during sports activities. Additionally, fiberglass fabric can also provide flexibility and enhance the overall performance of the equipment by improving its torsional and bending properties. Therefore, fiberglass fabric is commonly used as a reinforcement material in sports equipment to enhance their strength, durability, and performance.

- Q: How is fiberglass fabric used in the production of protective gloves?

- Fiberglass fabric is commonly used in the production of protective gloves due to its unique properties that make it an ideal material for providing protection against various hazards. The fabric is made from fine fibers of glass, which are woven together to create a strong and durable material. One of the key benefits of using fiberglass fabric in protective gloves is its excellent heat resistance. The fabric can withstand high temperatures without melting or degrading, making it suitable for applications where heat protection is crucial. In industries such as welding, metalworking, or firefighting, where workers are exposed to extreme heat or flames, fiberglass fabric gloves can provide a reliable barrier against thermal hazards. Furthermore, fiberglass fabric is highly resistant to cuts, abrasions, and punctures. This characteristic is crucial in industries such as construction, manufacturing, or automotive where workers handle sharp objects or work with machinery that poses a risk of injury. The fabric's durability ensures that the gloves can withstand the rigors of these environments, preventing cuts or punctures from occurring and offering reliable protection to the wearer. Another advantage of fiberglass fabric is its resistance to chemical exposure. Many industrial jobs involve handling hazardous chemicals or substances that can cause skin irritation or burns. Fiberglass fabric gloves act as an effective barrier against these chemicals, preventing direct contact and minimizing the risk of harm. Additionally, fiberglass fabric gloves are lightweight and flexible, allowing for dexterity and ease of movement. This is particularly important in industries where workers require precise hand movements, such as electronics, precision engineering, or laboratory work. The gloves enable the wearer to maintain a high level of control and grip, while still providing the necessary protection. In summary, fiberglass fabric is used in the production of protective gloves due to its exceptional heat resistance, cut and puncture resistance, chemical resistance, and flexibility. By leveraging these properties, fiberglass fabric gloves ensure the safety of workers in various industries, protecting them from thermal hazards, cuts, abrasions, chemical exposure, and allowing for precise hand movements.

- Q: Is fiberglass fabric resistant to pests in agricultural settings?

- Yes, fiberglass fabric is generally resistant to pests in agricultural settings. Its non-porous and smooth surface makes it difficult for pests to chew through or attach to, making it an effective barrier against common agricultural pests such as rodents, insects, and birds. Additionally, fiberglass fabric is not susceptible to rot or decay, further preventing pest infestations.

- Q: Asphalt + glass fiber cloth

- First spread a layer of asphalt oil, wrapped in glass cloth, oil cloth, and finally coated asphalt oil. Just OK

- Q: What are the different fiberglass fabric coatings for flame retardancy?

- Enhancing the flame retardant properties of fiberglass fabric can be achieved through the application of various coatings. Some coatings commonly utilized include: 1. Silicone: Renowned for their exceptional heat resistance and ability to form a protective barrier against flames, silicone coatings are ideal for extended exposure to high temperatures, ensuring long-term flame resistance. 2. Polyurethane: A flexible and durable flame retardant layer can be achieved on fiberglass fabric with the use of polyurethane coatings. These coatings offer resistance to abrasion and maintain effectiveness even after repeated exposure to flames. 3. Acrylic: Lightweight and providing resistance to flames and chemicals, acrylic coatings strike a balance between flame retardancy and flexibility. Applications such as protective clothing often require this type of coating. 4. PVC: Widely employed in the production of flame retardant fiberglass fabric, polyvinyl chloride (PVC) coatings deliver excellent flame resistance. These coatings find extensive use in industrial settings and for protective purposes. It should be noted that selecting the appropriate coating depends on specific application requirements. Factors like desired flame retardancy level, flexibility, durability, and cost all contribute to determining the most suitable coating for a particular use case.

- Q: Glass steel can be embedded parts

- Can be embedded normal.

- Q: How does fiberglass fabric perform in terms of flexibility?

- Fiberglass fabric is known for its exceptional flexibility. Due to its composition of fine glass fibers, it can be easily molded and bent into various shapes and contours without losing its structural integrity. This flexibility makes fiberglass fabric highly versatile and suitable for a wide range of applications. It can be used in industries such as automotive, aerospace, construction, and even fashion, where flexibility and adaptability are crucial. Additionally, fiberglass fabric can withstand repeated bending and stretching without experiencing significant wear or tear, making it a durable choice for projects that require long-term flexibility. Overall, fiberglass fabric performs exceptionally well in terms of flexibility, offering designers and manufacturers the freedom to create innovative and dynamic products.

Send your message to us

Fiberglass Fabrics from Malaysia Supplier - Fiberglass Geogrid for Airport Road Protection - Hot Sell

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords