Fiberglass Fabrics - Coated Fiberglass Fabric with Different Specifications

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

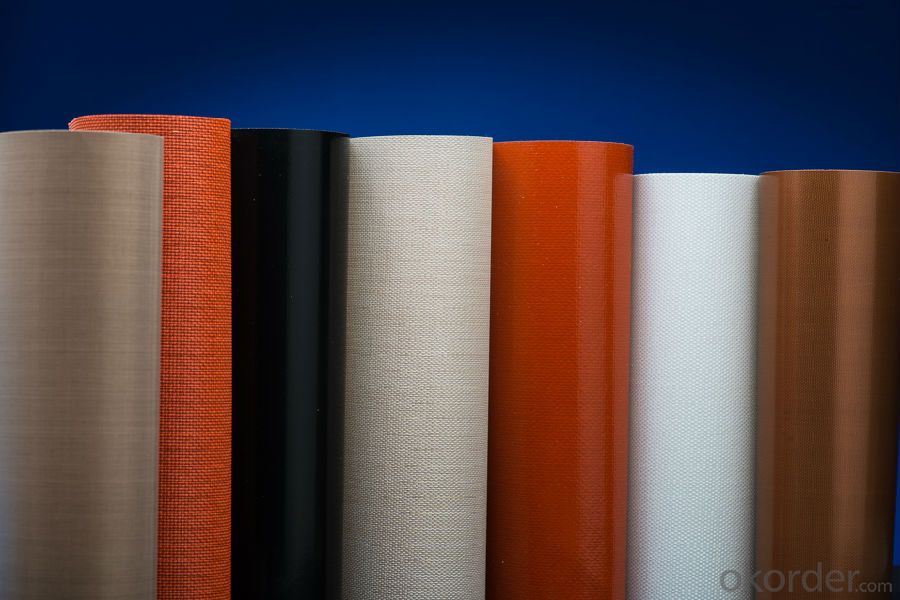

Coatecd Fiberglass Fabric with Different Specification

Fiberglass Fabric Description

Silicone coated fiberglass fabric are made of fine fiberglass with excellent capacity of high temperature and corrosion resistance, coated and rolled with silicone rubber, which is a brand new product with good performance and multiple applications.

Fiberglass Fabric Specification

Thickness:0.2mm-5mm

Width:100cm-150cm

Color;grey/red/silver/black

Weight(coating):130gsm-2800gsm

Model No | FSD2030 | FSD2030 | FSD2050 | FSD2100 | |

High temperature resistant(°C) | ≤280 | ≤280 | ≤280 | ≤280 | |

Low temperature resistant(°C) | ≥-40 | ≥-40 | ≥-40 | ≥-40 | |

Tensile intensity (N/50mm) | Warp | ≥1750 | ≥1750 | ≥2500 | ≥3500 |

Weft | ≥1280 | ≥1280 | ≥2100 | ≥3000 | |

Inflating burst intensity(Mpa) | ≥2.0 | ≥2.0 | ≥2.2 | ≥2.6 | |

Peeling intensity(N/m) | ≥450 | ≥450 | ≥520 | ≥600 | |

Insulation (kv/mm) | 16 | 16 | 18 | 18 | |

Weight (g/m*m) | 550-650 | 550-650 | 750-800 | 1500-1800 | |

Width(mm) | 1000±20 | 1000±20 | 1000±20 | 1000±20 | |

Thickness(mm) | 0.3-0.4 | 0.3-0.4 | 0.05-0.55 | 1.0-1.1 | |

color | Silver-gray, gray, red | lucency | Silver-gray, gray, red | Black, gray, red | |

Fiberglass Fabric Features:

1, Good performance on resisting high temperature and low temperature, -40°C-280°C;

2, High strength;

3, Ozone, oxide, light and weather aging resistance;

4, High insulation: dielectric constant:3-3.2, breakdown voltage: 20-50KV/MM;

5, Chemical corrosion resistant, oil-proofing, waterproofing (washable)

Fiberglass Fabric Application:

1) Electric insulation: it feature high grade of electric insulation and bear a load of high voltage. It fits for making products like insulation cloth and sleeves et.

2) Non - metalli compensator: used as pipeline oupling, non-metallic compensactor helps to avoid damage caused by heat expansion and cold contraction. This membrane material speially fit for using in industres of petroleum, chemical engineering, cement, iron and steel and good elasticity and toughness.

3)Anti-conrrosion sector: It is good to be used as inner and outer anti-corrosion layer featuring excellent corrosion resistance, tempareture resistance and high strength. It proves to be an ideal anti-corrosion material.

4) Others: Apart from above application, it can also be used as sealing material, temperature resistant and anti-orrosion conveyr belt and packaging material.

Product Show

FAQ

1.What are the characteristics of fiberglass fabric?

a)Outstanding temperature resistance(from -70°C to +260°C)

b)Excellent chemical resistance

c)Superior non-stick surface, easy to clean

d)High dielectric strength

e)Dimensional stability

f)Resistance to UV, IR and HF

g)Non-toxic

2.How many methods to weave the fabric?

Four methods to weave the fabric:

a).Plain weave: it can be used in electricity insulation materials and reinforced materials in industry, because of inseparable structure, plain and clear lines.

b).Twill weave: compared with plain weave, it is of high density, high intensity, with a soft and loose structural weave. It can be used in ordinary reinforced materials, filter materials, and painting cloth.

3.Can you offer us some samples?

We are willing to offer our customers best product&service,if it's necessary we can send

you sample for test;also we welcome all you customer have a trial order.

- Q: How does fiberglass fabric perform in extreme temperatures in HVAC systems?

- Fiberglass fabric is known for its excellent performance in extreme temperatures within HVAC systems. It is an ideal material for insulation due to its ability to withstand high temperatures without losing its structural integrity or insulation properties. In high-temperature environments, fiberglass fabric acts as a barrier, preventing the transfer of heat between different areas of the HVAC system. It effectively traps heat within the desired space, ensuring energy efficiency and minimizing heat loss. Similarly, in cold temperatures, fiberglass fabric acts as an insulator, preventing heat from escaping and maintaining a consistent temperature within the HVAC system. This helps to reduce energy consumption and ensures optimal performance. Additionally, fiberglass fabric is resistant to fire and does not release toxic gases when exposed to extreme temperatures. This makes it a safe choice for HVAC systems, as it does not contribute to the spread of fires or pose a health hazard in case of accidental overheating. Another advantage of fiberglass fabric in extreme temperatures is its durability and longevity. It does not degrade or deteriorate when exposed to high or low temperatures, making it suitable for long-term use in HVAC systems. It can withstand the thermal cycling that occurs within the system without losing its insulating properties or structural integrity. Overall, fiberglass fabric is a reliable and effective material for extreme temperatures in HVAC systems. It provides insulation, energy efficiency, safety, and durability, making it a popular choice for various HVAC applications.

- Q: Can fiberglass fabric be used for insulation in silos?

- Yes, fiberglass fabric can be used for insulation in silos. Fiberglass fabric is known for its excellent thermal insulation properties, making it suitable for insulating silos and maintaining optimal temperature levels inside.

- Q: Can fiberglass fabric be used for curtains and drapes?

- Yes, fiberglass fabric can be used for curtains and drapes. It is a versatile material that offers durability, resistance to fire, and is lightweight. Additionally, fiberglass fabric can provide privacy while allowing natural light to filter through.

- Q: How is fiberglass fabric cut and shaped?

- Fiberglass fabric is typically cut and shaped using a few different methods. One common method is to use scissors or a utility knife to cut the fabric to the desired size and shape. This method is commonly used for smaller or more intricate cuts. For larger cuts or more precise shaping, a technique called "hot knife cutting" is often employed. This involves using a heated blade or wire to cleanly cut through the fiberglass fabric. The heat helps to seal the edges of the fabric, preventing fraying and ensuring a smooth finish. Another method used for shaping fiberglass fabric is molding. In this process, the fabric is laid over a mold or form and then a resin or adhesive is applied to secure it in place. The fabric is then allowed to cure or harden, taking on the shape of the mold. This method is commonly used in the production of fiberglass products such as boat hulls or automotive parts. Overall, the cutting and shaping of fiberglass fabric requires precision and attention to detail. Whether using scissors, a hot knife, or molding techniques, it is important to ensure clean cuts and proper shaping in order to achieve the desired result.

- Q: Can fiberglass fabric be used for making backpacks?

- Yes, fiberglass fabric can be used for making backpacks. It is a durable and lightweight material that is resistant to wear and tear, making it suitable for backpacks that require strength and longevity. Additionally, fiberglass fabric is also water-resistant, adding an extra layer of protection to the contents of the backpack.

- Q: How does fiberglass fabric handle chemicals and solvents?

- Fiberglass fabric is known for its excellent resistance to a wide range of chemicals and solvents. The unique properties of fiberglass, such as its non-reactivity and high chemical resistance, make it an ideal material for various industries that deal with corrosive substances. The structure of fiberglass fabric, which is composed of woven glass fibers, provides exceptional resistance to chemical attack. It is highly resistant to most acids, bases, and organic solvents. This makes it suitable for applications where exposure to corrosive chemicals is common, such as in chemical processing plants, laboratories, and oil refineries. One of the key advantages of fiberglass fabric is its ability to maintain its physical integrity and mechanical strength when exposed to various chemicals and solvents. Unlike some other materials that can degrade or become brittle when in contact with certain substances, fiberglass fabric remains stable and durable. This ensures that it can withstand the harsh conditions and continue to perform effectively over extended periods. Another benefit of fiberglass fabric is its low permeability to chemicals and solvents. This means that it acts as a barrier, preventing the passage of harmful substances through its surface. This property is particularly valuable in applications where containment is crucial, such as in storage tanks, pipelines, and chemical-resistant linings. In addition to its resistance to chemicals and solvents, fiberglass fabric also offers other desirable properties. It is lightweight, flexible, and has excellent thermal insulation properties. These characteristics make it a versatile material that can be used in a wide range of applications where both chemical resistance and structural integrity are required. However, it is important to note that while fiberglass fabric is highly resistant to most chemicals and solvents, there are some exceptions. Certain strong acids, such as hydrofluoric acid, can attack fiberglass and cause degradation. Additionally, prolonged exposure to certain solvents like acetone or chloroform may cause swelling or softening of the fabric. Overall, fiberglass fabric is a reliable and durable material that can handle a wide range of chemicals and solvents. Its excellent chemical resistance, combined with its other beneficial properties, make it a preferred choice for many industries where protection against corrosive substances is essential.

- Q: Is fiberglass fabric resistant to chemicals and solvents?

- Fiberglass fabric is typically resistant to chemicals and solvents. Its composition of interwoven glass fibers grants it a strong resistance to a diverse array of chemicals and solvents, encompassing acids, alkalis, and organic solvents. This resistance renders fiberglass fabric highly sought-after for a multitude of applications where exposure to chemicals and solvents is anticipated, such as in chemical processing plants, laboratories, and industrial settings. Nevertheless, it is essential to acknowledge that the degree of resistance may vary based on the precise type and quality of fiberglass fabric, thus consulting the manufacturer or supplier for detailed chemical compatibility information is always advisable.

- Q: What is the difference between epoxy fiber glass cloth flooring and anticorrosive floor?

- The two floor effect is not very ideal, for one or two years will appear after the cracking and hollowing phenomenon of pit even powdering.

- Q: Can fiberglass fabric be used for reinforcement in boat hulls?

- Fiberglass fabric is indeed capable of reinforcing boat hulls. Its high strength-to-weight ratio, durability, and resistance to water and corrosion make it a popular choice for boat construction. Typically, fiberglass fabric is laid up in multiple layers and combined with a resin, such as polyester or epoxy, to create a composite structure. This composite material enhances the stiffness and strength of the hull, making it more resistant to impacts and flexing. In addition, fiberglass fabric can be easily molded into intricate shapes, allowing it to reinforce various parts of a boat hull. In conclusion, fiberglass fabric is a versatile and dependable option for reinforcing boat hulls, which explains its widespread use in the marine industry.

- Q: What are the different fiberglass fabric finishes for fire resistance?

- There are several different fiberglass fabric finishes available for fire resistance. One popular finish is a silicone coating, which provides excellent resistance to flames and high temperatures. This coating forms a protective barrier on the fabric, preventing the spread of flames and reducing the risk of ignition. Another common finish is an acrylic coating, which also offers good fire resistance properties. Acrylic coatings create a flame-retardant barrier that can withstand high temperatures and prevent the fabric from catching fire. Additionally, some fiberglass fabrics may have a vermiculite coating, which is a mineral-based finish that expands when exposed to heat, creating a protective thermal barrier. This coating helps to insulate the fabric and delay the spreading of flames. Furthermore, some manufacturers may offer fiberglass fabrics with a PTFE (polytetrafluoroethylene) coating, which is known for its exceptional heat resistance. PTFE coatings can withstand extremely high temperatures and provide a durable fire-resistant finish. These various fiberglass fabric finishes for fire resistance offer different levels of protection and are suitable for different applications, depending on the specific requirements and regulations.

Send your message to us

Fiberglass Fabrics - Coated Fiberglass Fabric with Different Specifications

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords