Glass Fiber Textiles - Fiberglass Fabric, Cloth, Rope & Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Fabric / Fiberglass Cloth / Fiberglass Rope / Fiberglass Tape

- Textured fiberglass textiles are composed of cloth, tape, twisted or braided rope etc.

- Having a maximum continuous operating temperature of 550℃.

Advantage of Textured Fiberglass Textiles

- Low thermal conductivity

- Electricity insulation

- Corrosive resistance

Application of Textured Fiberglass Textiles

Textured fiberglass textiles can be performed in process industries as fire curtains, gaskets or sealing in kiln, furnace and heaters etc. Application has been extended to the building industry as reinforcement material.

Size of Textured Fiberglass Cloth

Thickness:0.8mm-4mm (0.032"-0.157")

Width:800mm-1830mm (31.5"-72.05")

Size of Textured Fiberglass Tape

Thickness:0.8mm-6mm (0.032"-0.236)

Width:13mm-750mm(0.512"29.53")

Size of Textured Fiberglass Twisted Rope

Diameter.3mm-50mm(1/8"-2)

Size of Textured Fiberglass Round Rope

Diameter:4mm-50mm(4/25"-2")

Size of Textured Fiberglass Square Rope

Diameter:4mm-50mm(4/25"-2)

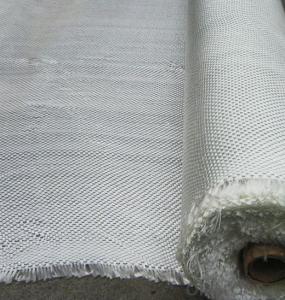

Photo of Fiberglass Texitle

- Q: Can glass fiber textiles be used in footwear?

- Yes, glass fiber textiles can be used in footwear. Glass fiber textiles are known for their strength and durability, making them suitable for various applications, including footwear. They are commonly used in the production of safety shoes, work boots, and sports shoes. Glass fiber textiles provide excellent reinforcement and support to the footwear, making them more resistant to tearing and stretching. Additionally, they can enhance the stability and structural integrity of the shoe, ensuring better performance and longevity.

- Q: Can glass fiber textiles be used for making curtains or blinds?

- Yes, glass fiber textiles can be used for making curtains or blinds. Glass fiber textiles are durable and have excellent heat and fire resistance properties, making them suitable for use in curtains or blinds. They can effectively block out sunlight and provide privacy while also offering insulation benefits. Additionally, glass fiber textiles are resistant to moisture, mold, and mildew, making them a good choice for areas with high humidity. Overall, glass fiber textiles can be a practical and stylish option for curtains or blinds in residential or commercial settings.

- Q: How do glass fiber textiles resist heat transfer?

- The resistance of glass fiber textiles to heat transfer is due to the unique properties of the glass fibers themselves. Glass fibers possess a low thermal conductivity, meaning they are not proficient at conducting heat. When heat is applied to the surface of the glass fiber textile, the fibers do not readily transmit the heat to other areas of the textile. This characteristic aids in minimizing the transfer of heat from one side of the textile to the other. Moreover, glass fibers possess a high melting point, typically around 1500 degrees Celsius. This elevated melting point enables glass fiber textiles to endure high temperatures without melting or deteriorating. Instead of melting, the glass fibers retain their structural integrity, thereby further contributing to their heat resistance capabilities. Furthermore, glass fiber textiles can be equipped with an additional layer of insulation, such as aluminum foil or a ceramic coating. These coatings serve as a barrier that reflects heat radiation and prevents it from infiltrating the textile. This supplementary insulation elevates the heat resistance of the glass fiber textile, rendering it even more effective in resisting heat transfer. In conclusion, glass fiber textiles resist heat transfer by virtue of their low thermal conductivity, high melting point, and, in certain instances, added insulation. These properties make glass fiber textiles highly suitable for applications that demand heat resistance, including insulation materials, protective clothing, and fire-resistant barriers.

- Q: Are glass fiber textiles resistant to electricity?

- Yes, glass fiber textiles are resistant to electricity.

- Q: How do glass fiber textiles resist rodents?

- Glass fiber textiles resist rodents because the material is not appealing to them for nesting or chewing purposes. The smooth and hard texture of the glass fibers makes it difficult for rodents to grip or penetrate, discouraging them from damaging or accessing the textile.

- Q: Can glass fiber textiles be used in marine applications?

- Glass fiber textiles are indeed applicable for marine uses. Renowned for their remarkable strength, durability, and ability to resist corrosion, these textiles prove to be a fitting material for a wide range of marine applications. It is commonplace to utilize them in the construction of boats, yachts, and other marine vessels, as their considerable tensile strength and lightweight nature are highly coveted qualities. Moreover, the manufacturing of marine equipment, including hulls, decks, and components demanding outstanding strength-to-weight ratios, also benefits from the utilization of glass fiber textiles. Furthermore, their resistance to water and chemicals renders them an optimal choice for marine applications where exposure to such elements is prevalent.

- Q: How do glass fiber textiles resist UV degradation?

- Glass fiber textiles resist UV degradation due to the inherent properties of glass, which is naturally resistant to UV radiation. The composition and structure of glass fiber make it highly durable and capable of withstanding the damaging effects of prolonged exposure to sunlight. Additionally, glass fiber textiles can be further enhanced with UV-resistant coatings or additives to provide an added layer of protection against UV degradation.

- Q: Can glass fiber textile be used in satellite dishes?

- Yes, glass fiber textile can be used in satellite dishes. Glass fiber, also known as fiberglass, is a lightweight and durable material that is commonly used in the construction of satellite dishes. It has excellent electrical insulation properties and can effectively transmit and receive signals. The use of glass fiber textile in satellite dishes allows for efficient signal reception and transmission, resulting in high-quality audio and video for satellite communication. Additionally, glass fiber textile is resistant to corrosion and can withstand harsh weather conditions, making it a suitable choice for satellite dishes that are often exposed to outdoor elements. Overall, glass fiber textile is an effective and reliable material for the construction of satellite dishes.

- Q: What is the tensile strength of glass fiber textiles?

- The tensile strength of glass fiber textiles can vary due to various factors, including the manufacturing process, type of glass, and specific application. However, glass fiber textiles are generally recognized for their superior tensile strength when compared to other textile materials. On average, glass fiber textiles exhibit a tensile strength ranging from 2000 to 5000 megapascals (MPa), which far surpasses materials like cotton or polyester. This exceptional strength renders glass fiber textiles suitable for applications that demand durability and robustness, such as reinforcement in the construction industry or in the production of composite materials. It should be noted that fabric construction, fiber orientation, and any additional coatings or treatments applied to the textiles can also influence the tensile strength.

- Q: What about polyester fiber and flannel? Is flannel made of polyester?

- Flannel: a transliteration of the English word "flannel", invented in England in eighteenth Century.With a soft woolen yarn made of textile and suede fabric. Originally meant a woolen fabric.

Send your message to us

Glass Fiber Textiles - Fiberglass Fabric, Cloth, Rope & Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords