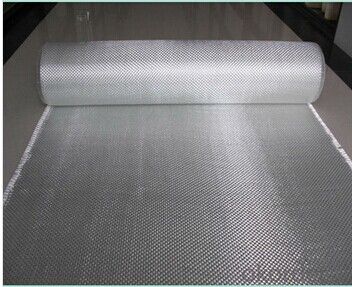

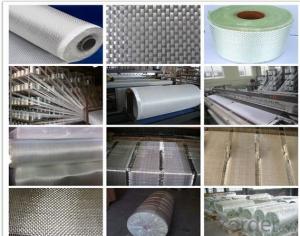

Glass Fiber Textiles Woven Roving Cloth Fabric

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 3000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description

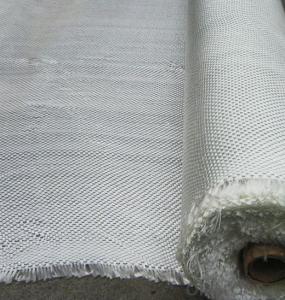

1.Glass woven roving are bidirectional fabric made by direction roving in plain weave pattern.

2.Compatible with unsaturated polyester ,vinyl resin ,epoxy resin .

3.Applicable for hand lay-up ,winding and compress molding process ,suitable for manufacturing tank ,boat ,automobile parts ,and other FRP product

Products advantage

1.Consistent thickness and excellent surface treatment .

2.Rapid impregnating and good compatibility with resin.

3.Uniform tension , high dimensional stability and easy to operate.

4.Good mechanical properties and high strength

5.Factory produce and product ISO certificated

1 Muti-resin-compatible

2 Easy shape adaptation

3 Easy impregnation

4 Good transparency

5 Excellent mechannical properties

product code | area weight | density warp*weft | tex | combustible content |

EWR200 | 200 | 4.6*4.6 | 200*200 | 0.4-0.8 |

EWR 270 | 270 | 4.6*4.1 | 300*300 | |

EWR360 | 360 | 3.2*1.8 | 600*900 | |

EWR400 | 400 | 3.6*3.2 | 600*600 | |

EWR450 | 450 | 3.2*2.8 | 600*900 | |

EWR500 | 500 | 2.2*2.0 | 1200*1200 | |

EWR580 | 580 | 2.6*2.2 | 1200*1200 | |

EWR600 | 600 | 2.6*2.4 | 1200*1200 | |

EWR800 | 800 | 2.0*1.6 | 2400*2400 |

- Q: Can glass fiber textiles be used in insulation?

- Indeed, insulation can utilize glass fiber textiles. Fiberglass textiles, also referred to as glass fiber textiles, are frequently employed in insulation materials owing to their remarkable thermal characteristics. Possessing a low thermal conductivity, they effectively diminish heat transfer and uphold temperature uniformity. Furthermore, glass fiber textiles are lightweight and pliable, facilitating trouble-free installation in a multitude of applications including walls, roofs, and pipes. Moreover, they exhibit resistance against fire, moisture, and chemicals, rendering them a resilient and enduring alternative for insulation purposes.

- Q: How do glass fiber textiles affect thermal comfort?

- Glass fiber textiles can improve thermal comfort by providing insulation and reducing heat transfer. These textiles have low thermal conductivity, which helps in keeping the body warm in cold conditions and preventing heat from entering during hot weather. Additionally, they have good breathability and moisture-wicking properties, allowing sweat to evaporate and keeping the body dry, enhancing overall comfort.

- Q: Can glass fiber textile be used in wind turbine blades?

- Yes, glass fiber textile can be used in wind turbine blades. Glass fiber textiles are commonly used in the construction of wind turbine blades due to their high strength, lightweight nature, and excellent resistance to environmental elements. These properties make glass fiber textiles an ideal choice for manufacturing wind turbine blades, enabling them to efficiently harness wind energy for electricity generation.

- Q: Can glass fiber textiles be used in extreme temperatures?

- Yes, glass fiber textiles can be used in extreme temperatures. Glass fiber is known for its high temperature resistance, making it suitable for use in various industries and applications that require materials to withstand extreme heat. Glass fiber textiles can typically withstand temperatures as high as 1000°C (1832°F) without losing their structural integrity or performance. This makes them ideal for use in applications such as insulation, fireproofing, and protective clothing in environments with high temperatures. Additionally, glass fiber textiles have excellent thermal insulation properties, which further enhances their ability to withstand extreme temperatures.

- Q: How are glass fiber textiles used in the automotive industry?

- Glass fiber textiles are used in the automotive industry for various applications such as reinforcing body panels, improving impact resistance, and reducing vehicle weight. They are also used in the production of insulation materials, soundproofing components, and reinforcing the structure of automotive interiors.

- Q: Can glass fiber textile be printed on?

- Yes, glass fiber textile can be printed on. The process of printing on glass fiber textile involves applying ink or dye onto the surface of the textile using various printing techniques such as screen printing, digital printing, or heat transfer printing. However, it is important to note that due to the smooth and non-absorbent nature of glass fiber, special inks or dyes and printing techniques may be required for successful printing. These specialized materials and techniques ensure proper adhesion and long-lasting prints on glass fiber textiles.

- Q: What is the cost of glass fiber textile?

- The cost of glass fiber textiles can vary depending on various factors such as the type of glass fiber used, the weight or density of the fabric, the manufacturing process, and the supplier or brand. Generally, glass fiber textiles are available in a range of prices to suit different budgets and requirements. It is best to contact suppliers or manufacturers directly to get specific pricing information based on your needs.

- Q: How do glass fiber textiles contribute to lightweight construction?

- Glass fiber textiles contribute to lightweight construction in several ways. Firstly, glass fiber textiles are made from extremely thin strands of glass, which are then woven together to create a fabric. This results in a material that is significantly lighter than traditional construction materials such as steel or concrete. This reduced weight is especially important in industries such as aerospace and automotive, where every kilogram saved can have a significant impact on fuel efficiency and overall performance. Secondly, glass fiber textiles have a high strength-to-weight ratio. Despite being lightweight, they offer excellent tensile strength, meaning they can withstand a significant amount of stress and load without breaking or deforming. This makes them a suitable alternative to heavier materials, as they can provide similar structural integrity while reducing the overall weight of the construction. Additionally, glass fiber textiles are corrosion-resistant. Unlike metals, which can be prone to rust and degradation over time, glass fiber textiles do not corrode. This makes them particularly suitable for applications in environments that are exposed to moisture or chemicals, as they can maintain their strength and durability over extended periods of time. Furthermore, glass fiber textiles offer excellent thermal and electrical insulation properties. They do not conduct heat or electricity, making them ideal for applications where temperature control or electrical safety is crucial. In addition, their insulation properties can help reduce energy consumption by minimizing heat transfer and improving energy efficiency. Lastly, glass fiber textiles are highly versatile and can be molded into various shapes and forms. This allows for greater design flexibility and the creation of complex structures with intricate geometries. The ability to tailor the material to specific requirements further contributes to lightweight construction, as it allows for optimized designs that maximize strength while minimizing weight. In conclusion, glass fiber textiles contribute to lightweight construction by being inherently lightweight, strong, corrosion-resistant, thermally and electrically insulating, and versatile. These properties make them ideal for a wide range of applications where reducing weight is a key priority, enabling the development of lighter, more efficient, and sustainable structures.

- Q: Are glass fiber textiles suitable for outdoor applications?

- Glass fiber textiles, without a doubt, are a perfect fit for outdoor applications. Renowned for their remarkable durability and ability to withstand harsh weather conditions, glass fiber textiles are highly resistant to UV radiation, moisture, and temperature fluctuations. This exceptional resistance makes them an impeccable choice for outdoor usage. The versatility of glass fiber textiles is evident in their suitability for various applications including outdoor furniture, awnings, canopies, and protective covers. Notably, they offer exceptional strength and stability, enabling them to endure heavy wind loads and other external forces. Furthermore, their lightweight nature and ease of handling make glass fiber textiles a practical option for outdoor applications.

- Q: Can glass fiber textiles be used in geotextiles and civil engineering projects?

- Yes, glass fiber textiles can be used in geotextiles and civil engineering projects. Glass fiber geotextiles are commonly used in civil engineering applications due to their high strength, durability, and resistance to chemicals and harsh environmental conditions. These textiles are often used as reinforcing materials in soil stabilization, erosion control, and slope protection projects. Glass fiber geotextiles provide reinforcement to weak soils, improving their load-bearing capacity and preventing soil erosion. They can be used in the construction of retaining walls, embankments, and foundations to enhance their stability and longevity. Additionally, glass fiber geotextiles can be used as separation layers between different soil types or as a filter to prevent the migration of fine particles while allowing water to pass through. Glass fiber textiles are also beneficial in civil engineering projects as they have high tensile strength, which makes them suitable for reinforcing concrete structures. Glass fiber-reinforced polymer (GFRP) bars or grids can be embedded in concrete to increase its strength and durability, making it more resistant to cracking and corrosion. In summary, glass fiber textiles have proven to be versatile and reliable materials in geotextiles and civil engineering projects. They offer excellent reinforcement, durability, and chemical resistance, making them suitable for various applications in soil stabilization, erosion control, and concrete reinforcement.

Send your message to us

Glass Fiber Textiles Woven Roving Cloth Fabric

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 3000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords