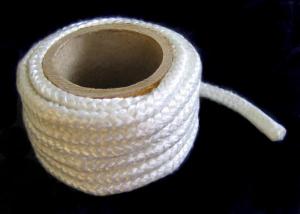

Glass Fiber Textiles Textured Fiberglass Round Braided

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5t kg

- Supply Capability:

- 2*20FCL Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General info of Textured Fiberglass Round Braided

1. Fire fiberglass rope is made of continuous filament texturized C or E glass yarns and is extremely strong, resilient, and flexible.

2. Fire fiberglass rope are asbestos free, cause no harm to health, making them ideal replacements to asbestos ones.

3. For higher loads, the round braided and square braided ropes can be reinforced by steel wires.

4. Fire fiberglass rope also can be coated with graphite or vermiculite to increase thermal insulation and abrasive resistance.

Fire Fiberglass Rope Application:

1. Fire fiberglass rope are widely used as gasket for industrial ovens and furnaces, boilers and wood burning stoves.

Specifications of Textured Fiberglass Round Braided

1. Fire Fiberglass Rope 2. Round braided or square braided 3. Temperature: 450C-550C 4. Thickness:3mm-100mm

- Q: Can glass fiber textile be used in corrosion-resistant materials?

- Yes, glass fiber textile can be used in corrosion-resistant materials. Glass fiber textiles, also known as fiberglass textiles, are made from woven or knitted strands of glass fibers. These fibers are resistant to corrosion from most chemicals, moisture, and UV radiation. When used as reinforcement in corrosion-resistant materials, such as composites or coatings, glass fiber textiles can enhance the overall corrosion resistance of the material. The high strength-to-weight ratio of glass fibers also makes them a suitable choice for applications where corrosion resistance is required, such as in the construction of chemical storage tanks, pipes, or marine structures. Additionally, glass fiber textiles can be combined with various resin systems to create corrosion-resistant laminates or coatings that provide excellent protection against corrosive environments. Overall, glass fiber textiles offer a viable solution for incorporating corrosion resistance into materials and ensuring their durability in challenging conditions.

- Q: How do glass fiber textiles affect the breathability of fabrics?

- Glass fiber textiles can enhance the breathability of fabrics by providing better moisture management and increasing the airflow. These textiles have a high level of porosity, allowing air and moisture to pass through easily. This helps to regulate body temperature and prevent the build-up of sweat and humidity, making the fabric more comfortable to wear in various climates and activities.

- Q: What are the different printing options for glass fiber textile?

- Glass fiber textiles offer a range of printing options, each with distinct advantages and applications. Firstly, screen printing is a versatile and commonly used method. It utilizes a fine mesh screen with a stencil to transfer ink onto the fabric. This technique allows for precise and detailed designs and can accommodate various inks, including textured and metallic finishes. Alternatively, digital printing directly prints designs onto the glass fiber textile using specialized inkjet printers. This method produces high-resolution and vibrant colors, making it ideal for intricate patterns and gradients. It is particularly suited for small batch production and customization due to its setup-free nature. Heat transfer printing involves printing designs onto transfer paper with specialized inks and then transferring them onto the glass fiber textile using heat and pressure. This method enables the application of intricate designs and produces durable prints. It is commonly used for large-scale production and is well-suited for complex patterns and multicolor designs. Sublimation printing utilizes heat and pressure to transfer dye onto the glass fiber textile, resulting in vibrant and permanent prints. This method is often employed for polyester-based glass fiber textiles, as the dye sublimates and bonds with the fabric fibers. Sublimation printing offers excellent color fastness, making it popular for sportswear and custom apparel. Lastly, foil printing adds a luxurious and eye-catching effect to the glass fiber textile by applying metallic or pigmented foil. This technique can be achieved through heat transfer or screen printing methods. Considering factors such as design complexity, desired durability, and fabric type is crucial when selecting the appropriate printing method for glass fiber textiles. Each option mentioned above possesses unique characteristics and suitability for different applications.

- Q: Can glass fiber textile be used in insulation blankets?

- Indeed, insulation blankets can utilize glass fiber textile. These textiles, widely employed in insulation materials, offer remarkable attributes such as elevated thermal resistance, exceptional fire resistance, and low thermal conductivity. Their effectiveness lies in their ability to impede heat transfer, rendering them an ideal choice for insulation blankets. By capturing air pockets within their fibers, glass fiber textiles effectively reduce heat transfer through conduction and convection. Moreover, these textiles are lightweight, effortless to manipulate, and readily moldable into diverse shapes, including blankets, which accounts for their immense popularity in insulation applications.

- Q: Can glass fiber textiles be used in shoes or footwear?

- Yes, glass fiber textiles can be used in shoes or footwear. They are commonly utilized to reinforce certain areas of the shoe, provide stability, and enhance durability. The glass fibers offer strength and resilience, making them suitable for various applications in footwear manufacturing.

- Q: How does glass fiber textile perform in low-temperature environments?

- Due to its inherent properties and characteristics, glass fiber textile performs exceptionally well in low-temperature environments. It possesses a high resistance to cold temperatures, allowing it to maintain its structural integrity even in extreme cold conditions. Unlike other materials, glass fiber textile does not become brittle or lose its mechanical strength when exposed to low temperatures. The glass fibers utilized in the textile exhibit a low coefficient of thermal expansion, meaning they do not significantly contract or expand in response to temperature changes. This unique property ensures the textile remains stable and resistant to deformation or damage in low-temperature environments. Moreover, glass fiber textile possesses outstanding thermal insulation properties. It acts as an effective heat transfer barrier, preventing the loss of heat in cold environments. This insulation capability helps maintain a comfortable temperature within a given space, thereby reducing the need for additional heating and energy consumption. Furthermore, glass fiber textile is highly durable. It remains unaffected by moisture or frost, which are common occurrences in low-temperature environments. The textile is impervious to freezing and thawing cycles, ensuring its long-term performance and reliability. In conclusion, glass fiber textile is a dependable and efficient material for use in low-temperature environments. Its resistance to cold temperatures, thermal insulation properties, and durability make it an ideal choice for a wide range of applications, including insulation in buildings, protective clothing, and aerospace components.

- Q: How do glass fiber textiles resist staining?

- Due to their distinct properties and manufacturing process, glass fiber textiles exhibit resistance to staining. These textiles consist of minuscule glass strands interwoven to create a robust and enduring fabric. The glass fibers possess inherent resistance against numerous substances that typically cause staining, including oils, chemicals, and liquids. The non-porous surface of glass fiber textiles impedes the easy penetration of stains into the fabric. This characteristic renders them less susceptible to absorbing and retaining dirt, dust, and other substances that provoke staining. Instead, stains tend to remain on the fabric's surface, simplifying the cleaning and removal process. Furthermore, glass fiber textiles are frequently treated with specialized coatings or finishes to bolster their stain resistance. These treatments furnish an additional layer of protection against stains and enhance the fabric's resistance to dirt and grime. Moreover, these coatings facilitate effortless cleaning by preventing stains from settling and becoming more challenging to eliminate. Moreover, glass fiber textiles generally exhibit greater resistance to fading and discoloration caused by exposure to sunlight or harsh chemicals. Unlike other materials, such as natural fibers, the glass fibers remain unaffected by UV rays and chemical reactions. Consequently, glass fiber textiles maintain their original color and appearance for extended periods, diminishing the likelihood of staining or discoloration. In conclusion, the unique composition, non-porous surface, and special treatments of glass fiber textiles contribute to their exceptional resistance to staining. These properties make them an outstanding choice for applications where stain resistance is crucial, such as in upholstery, carpets, and other textile products.

- Q: Can glass fiber textile be used outdoors?

- Yes, glass fiber textile can be used outdoors. It is known for its durability, resistance to weather conditions, and ability to withstand UV radiation. These properties make it suitable for various outdoor applications such as outdoor furniture, awnings, canopies, and even in the construction industry for reinforcement and insulation.

- Q: How do glass fiber textiles compare to natural fiber textiles?

- Glass fiber textiles and natural fiber textiles have distinct characteristics and properties that set them apart from each other. Glass fiber textiles, also known as fiberglass textiles, are made from strands of spun glass. They offer several advantages over natural fiber textiles. Firstly, glass fiber textiles are highly durable and have excellent resistance to heat, chemicals, and moisture. This makes them suitable for applications where strength and resistance to environmental factors are crucial, such as in the automotive and aerospace industries. Additionally, glass fiber textiles have excellent dimensional stability, meaning they do not shrink or stretch easily. This property makes them ideal for use in applications where precision and accuracy are essential, like in the manufacturing of circuit boards or electrical insulation. On the other hand, natural fiber textiles, such as cotton, linen, or silk, have their own unique set of characteristics. Natural fibers are generally more breathable and comfortable to wear than glass fiber textiles, as they allow air circulation and moisture absorption. This makes them suitable for clothing and bedding materials, where comfort and softness are important factors. Natural fiber textiles are also biodegradable and environmentally friendly, as they are derived from renewable resources. They have a lower carbon footprint compared to glass fiber textiles, which require energy-intensive manufacturing processes. However, natural fiber textiles are generally less durable and have lower resistance to heat, chemicals, and moisture compared to glass fiber textiles. They may also be more prone to shrinking, stretching, or fading over time. In conclusion, glass fiber textiles and natural fiber textiles have their own distinct properties and advantages. The choice between the two depends on the specific requirements of the application. Glass fiber textiles are preferred for their durability, resistance to environmental factors, and dimensional stability, while natural fiber textiles are favored for their breathability, comfort, and biodegradability.

- Q: Can glass fiber textile be used in electrical insulation?

- Glass fiber textiles have the capability to be utilized in electrical insulation. These textiles are manufactured using delicate glass strands that possess exceptional insulation qualities. They are commonly employed as a strengthening component in electrical insulation items, including electrical tapes and insulating sleeves. Glass fiber textiles exhibit high resistance to heat, chemicals, and electricity, rendering them suitable for instances where electrical insulation is necessary. Moreover, they possess the advantages of being lightweight, flexible, and long-lasting, thereby facilitating easy handling and installation. In general, glass fiber textiles prove to be a dependable and efficient option for electrical insulation.

1. Manufacturer Overview

| Location | Beijing, China |

| Year Established | 1992 |

| Annual Output Value | Above US$ 3 Million |

| Main Markets | North America;Southeast Asia ;Western Europe ;Middle East |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjing |

| Export Percentage | 60% - 70% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 10,000 square meters |

| No. of Production Lines | Above 8 |

| Contract Manufacturing | |

| Product Price Range | High; Average |

Send your message to us

Glass Fiber Textiles Textured Fiberglass Round Braided

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 5t kg

- Supply Capability:

- 2*20FCL Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords