Fiberglass Ceiling Tiles 2x4 - Wall Panels in Different Colors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description

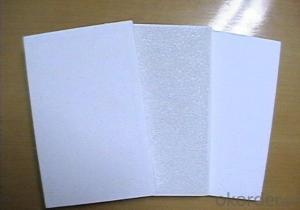

CMAX sound absorbing fiberglass ceiling is made from sound absorbing plate of fiberglass wool/Rock wool as basis material and on it compound sprayed fiberglass decorative felt. It features good sound absorbing effect, heat preservation, high fire retardant, high strength level , beautiful decorative effect, etc. it can improve acoustical environment of building and raise peoples quality of work and living. It is widely used for indoor space where not only has the requirement to drop noise but also the needs medium and high quality decoration, such as hospital, meeting room, exhibition hall, cinema, library ,studio, gymnasium , phonetic classroom, shopping place ,etc.

CHARACTERISTICS:

1. property of noise dropping

fiberglass wool/Rock wool is one of best sound absorbing materials. The sound absorbing coefficient , NRC of our ceiling is about 1.0 . sound wave can not produce echo on its surfacing, it can control and adjust effectively the time of reverberation and drop noise and improve timbre.

2. property of fireproof

It is fireproof level A ( non-flammable level)

3. property of heat preservation

the ceiling has good property of heat preservation. If apply to the place where exists air-condition, it can reduce the effect from environment to indoor temperature and save energy source effectively.

4. property of inhibit bacterium

The property of non-absorbing moisture makes any microbe has no environment and condition to exist and multiply.

5. property of level

Adapt double-facing fiberglass felt to compound. So it improves its strength and level greatly.

Detail specification and size:

type | thickness | density | size |

LR700 | 30MM | 100K | 600 X 600MM 600 X 1200MM 300 X 1200MM 600 X 1800MM 600 X 2400MM |

LR700 | 40MM | 100K | 600 X 600MM 600 X 1200MM 300 X 1200MM 600 X 1800MM 600 X 2400MM |

LR700 | 50MM | 100K | 600 X 600MM 600 X 1200MM 300 X 1200MM 600 X 1800MM 600 X 2400MM |

FAQ

1.Sample: small sample can be offered by free

2.OEM: OEM is accepted

3.MOQ: small order is ok

4.Test: any third party is accepted to test

5.Factory: Can visit factory any time

6.Delivery Time: small order is within 7days or according to your order

- Q: Magnesium oxide and magnesium chloride

- Magnesium chloride Uses: for the production of metal magnesium, disinfectant, frozen brine, ceramics, and used to fill the fabric, paper and so on. The solution is mixed with magnesium oxide, can become hard wear-resistant magnesia cement. Magnesium oxide is mainly used for the preparation of ceramic, enamel, refractory crucible and refractory bricks of raw materials. Also used as a polish, binder, coating and paper filler, chloroprene rubber and fluororubber accelerator and activator. And magnesium chloride and other solutions mixed, can be made of magnesium oxide water. Medicine for antacids and laxatives for gastric acid, stomach and duodenal ulcer disease. Raw materials used as catalysts and magnesium salts in the chemical industry. Also used for the production of glass, dyed meal, phenolic plastic and so on. Heavy-duty magnesia Milling industry for firing and grinding. The construction industry is used in the manufacture of artificial chemical flooring, artificial marble, heat shields and sound insulation panels. The plastic industry is used as a filler. It can also be used to produce other magnesium salts.

- Q: What is foam insulation

- Phenolic foam has "the king of insulation materials," the name, is a new generation of thermal insulation materials insulation. Phenolic foam in developed countries has developed rapidly, has been widely used in construction, defense, foreign trade, storage, energy and other fields. US construction industry used in the insulation foam, phenolic materials accounted for 40%; Japan has also set up phenolic foam popularization Association to promote this new material.

- Q: Our basement bedroom does not have insulation in ceiling between joists but it is possible to insulate from another area that is not finished but I would have to use the insulation which is blown in between the joists. Is this a good insulation and is it practical to do for noise reduction? Otherwise, we would have to tear out the ceiling in the bedroom and use the fiberglass insulation. Do you have any other ideas or suggestions for noise reduction? This is a new home.

- Noise reduction would be the greatest benefit, because the ceiling is not exposed to lower temperatures. If the joists are unobstructed by solid braces, there are insulators who bore a hole in each end between joists and pump in a foam type insulation. I have seen this done to outside walls on a house before putting on siding.

- Q: between 12 inches and 24 inches thick hallowblocks ceiling

- For ceiling the 24 inch thick is slightly better, but not for roof as more afternoon heat is stored in the increased mass of the 24 inch blocks. If the ceiling hollows are filled with fiberglass or rockwool, a 2% reduction in electric consumption is possible as the convection currents are reduced for both 12 inch and 24 inch hollow blocks. Neil

- Q: The working principle of optical fiber

- Optical fiber Mainly the use of the principle of total reflection, so that light only occurs, no refraction, loss is the smallest

- Q: We just bought a house and our ceiling has the cottage cheese texture to it and it is cracked and broken in many placed so my husband wants to just take it off. I have told him that it may contain asbestos but he thinks he can do it on his own. So we are going to get it tested and if it does he just wants to remove it himself. My question is, is this a job anyone can do?

- If it is asbestos it is hazardous material and should be removed by a company that is trained to remove that type of ceiling. Otherwise, you're could be putting yourselves at risk if you don't take the proper precautions.

- Q: Recently, the company looking for a house waterproof building materials are placed inside the ceiling, called linoleum paper (linen paper), also known as asphalt paper, English called Felt or Tar paper Alibaba can be found at present I want to find specifications and models are D-4869 1 * 20 meters but Alibaba is basically 17 to 18 kg but there are 5 to 7 kg of the situation, what is this situation?

- Can find the manufacturers, you call them directly to ask not better

- Q: What is the specific waterproofing of the bathroom? How much is the height of the wall As well as craftsmanship?

- Polyurethane waterproof coating general approach is as follows: 1, the ground to the direction of the ground to find slope, cement mortar or bean concrete can be, but the surface to be flat. Near the door slope is small, the gap near the slope, according to the specific situation to master. 2, the pipeline to wear the floor of the root, to strengthen the waterproof. Tube root construction seal seal, cement smoothing foot protection, brush waterproof coating when the paste from the wire to strengthen the layer 1 to 2 layers. The same measures around the floor drain. 3, the wall to deal with clean plain light without floating ash, small particles, wall ground junction to wipe the original angle or slope angle. Brush waterproof coating when the glass cloth to strengthen the layer 1 to 2 layers. 4, the total thickness of polyurethane waterproof coating requires more than 1.5 mm. Can not rely on the number of decisions. Root, corner reinforcement layer at the first brush, room temperature 4h dry, and then a large area of ??brushing, Tu scraping. There is no leakage scraping, bubbling phenomenon. Large area brushing 24h curing after brushing the next layer. 5, first brushing the facade after brushing the plane, the next brushing direction and the vertical again. The last time the film semi-curing, throwing coarse sand particles, easy to combine with the cement mortar in the future. 6, the ground waterproof layer should be painted out of the bathroom door outside the 300 wide. Waterproof surface waterproof layer should be higher than the ground 200, a shower bathroom wall waterproof layer should be higher than the ground 1800 (L8 recommended full wall waterproof).

- Q: Will the attic insulation how to do?

- Long life, much higher than other insulation materials.

- Q: General construction industry, building materials which, how classification? What

- Paint, paint, paint, paint, paint, paint, paint, paint, paint, paint, paint, paint, paint, paint, paint, paint, paint, paint Diluent, Glue, Sealant, White Glue, Double Glue, 107 Glue, Wallpaper Powder, Anti-Sealing Adhesive, Plastic Floor Adhesive, Adhesive Other, Glossy Wax, Car Wax, Polishing Paint, Talc , Polished copper oil, grinding sand, alumina, roller brush, row brush, wool brush, glass fiber cloth, floor paint, putty powder, talcum powder

Send your message to us

Fiberglass Ceiling Tiles 2x4 - Wall Panels in Different Colors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords