Aluminum Foil Facing Factory Shielding Copper Polyester Foil for Coaxial Cables

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Mylar foil Shielding Foil for Coaxial Cable communication cable

1.Structure of Aluminum Mylar foil Shielding Foil Description:

Electrical cable is used to transfer electricity, information and the realization of electromagnetic energy transformation. The electrical cable in a broad term mainly indicates to cable and in a narrow term indicate insulation material. Its definition is the aggregation of different parts below: one or more insulation cores, the wrapping layers of the cores, the general protective layers and the outer protective layers. Cables also include additive conductor without insulator.

2.Main Features of the Aluminum Mylar foil Shielding Foil:

Aluminum Mylar foil Shielding Foil is applicable to the shielding of coaxial cable, local network wire, electronic communication cable and computer peripheral wire etc.

1.Thickness: min 6.5mic; width: 300-1000mm.

2. According to GB/T 3198-2010.

3.Usages: cable shield, candy wrap

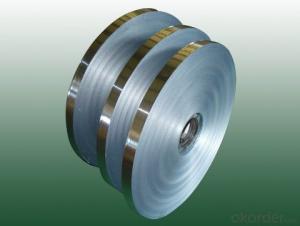

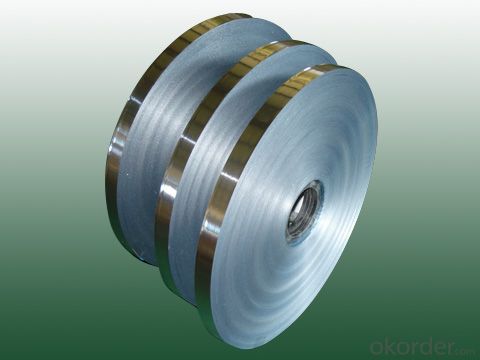

3. Aluminum Mylar foil Shielding Foil Images

4. Aluminum Mylar foil Shielding Foil Specification

AL-PET laminated foil

Description: Apply for overall or individual twisted pair shield for electronic cable and local network cables, protect from external electromagnetic interference. Features option of LUBRITAPE apply to decrease 50% friction of aluminum surface.

Construction: Aluminum foil, Polyester film

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | WEIGHT |

FP007012 | 22±3 | 7 | 3 | 12 | 38.8±5% |

FP010012 | 25±3 | 10 | 3 | 12 | 46.9±5% |

FP020020 | 43±3 | 20 | 3 | 20 | 83.8±5% |

FP025012 | 40±3 | 25 | 3 | 12 | 87.6±5% |

Special specifications are also available, according to customer’s order. | |||||

AL-PET-AL laminated foil

Description: resilient shielding in cable assembling and provide the enhanced shielding required in harsh environments.

Construction: Aluminum foil +Polyester film+ Aluminum foil

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | GLUE | ALU THICKNESS | WEIGHT |

DFP007015 | 35±3 | 7 | 3 | 15 | 3 | 7 | 65±5% |

DFP009020 | 39±4 | 9 | 3 | 15 | 3 | 9 | 76±5% |

DFP015025 | 61±5 | 15 | 3 | 25 | 3 | 15 | 115±5% |

DFP025025 | 80±5 | 25 | 3 | 25 | 3 | 25 | 175±5% |

Special specifications are also available, according to customer’s order. | |||||||

Bonded AL-PET laminated foil

Description: A laminated aluminum-polyester-aluminum tape is fully bonded to the foam dielectric to provide 100% coverage, longitudinally applied over the polyethylene core and the tape minimizes signal leakage.

Construction: Aluminum foil + Polyester film + Aluminum foil + EMAA film

CODE | TOTAL THICKNESS | ALU THICKNESS | GLUE | POLYESTER FILM | GLUE | ALU THICKNESS | GLUE | EMAA | WEIGHT |

DFPH009012 | 65±5 | 9 | 3 | 12 | 3 | 9 | 3 | 25 | 98±5% |

DFPH009020 | 72±5 | 9 | 3 | 20 | 3 | 9 | 3 | 25 | 108±5% |

DFPH009025 | 75±5 | 9 | 3 | 25 | 3 | 9 | 3 | 25 | 114±5% |

DFPH010025 | 84±5 | 10 | 3 | 25 | 3 | 10 | 3 | 25 | 126±5% |

Special specifications are also available, according to customer’s order. | |||||||||

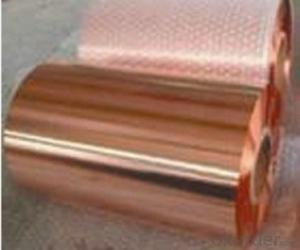

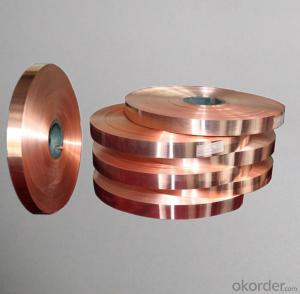

Copper polyester foil

Description: Copper foil, copper lamination foil typically use as shielding for low/medium voltage cable and radio frequency coaxial cable. The rolled annealing copper foil is flexible to wrap cable core, also it has the excellent physical properties, Polyester film provides electrical insulation and high mechanical properties.

Construction: Copper foil + Polyester film

CODE | TOTAL THICKNESS | CU THICKNESS | GLUE | POLYESTER FILM | WEIGHT |

CP018012 | 33±3 | 18 | 3 | 12 | 175±10% |

CP007020 | 46±3 | 18 | 3 | 25 | 195±10% |

CP015012 | 30±3 | 15 | 3 | 12 | 160±10% |

Special specifications are also available, according to customer’s order. | |||||

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① Where you used this foil?

Aluminum Mylar foil Shielding Foil is used for cable shield, candy wrap for the shielding of coaxial cable, local network wire, electronic communication cable and computer peripheral wire etc.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What are the methods to prevent grease stains on aluminum foil after using it for cooking?

- <p>To avoid grease stains on your aluminum foil facing after cooking, consider the following tips: Use a double layer of foil to increase protection, ensuring the foil is large enough to fully cover the cooking surface. Preheat your foil before placing it on the cooking surface to reduce the chance of grease sticking. Clean the foil immediately after use with warm soapy water to remove any grease before it sets. Alternatively, you can use non-stick spray or a light coating of oil on the foil before using it, which can help prevent grease from adhering.</p>

- Q: What are some frequent errors individuals commit when employing aluminum foil in culinary practices?

- <p>Common mistakes when using aluminum foil in cooking include: 1) Using foil that's too thin, leading to tearing during cooking. 2) Not allowing for proper air circulation, which can result in uneven cooking or steaming instead of roasting. 3) Wrapping foods too tightly, which can prevent even cooking and may cause the foil to stick to the food. 4) Using foil with non-stick coatings on the inside, which can flake off and contaminate the food. 5) Overlapping the foil edges, which can cause food to leak out. 6) Not using enough foil, which can lead to spills and messes in the oven. 7) Not preheating the oven before placing foil-wrapped foods inside, which can lead to uneven cooking. 8) Not greasing the foil before placing food on it, which can cause sticking. Proper use of aluminum foil can enhance cooking and prevent these issues.</p>

- Q: What are the safety regulations or guidelines that aluminum foil facing must adhere to?

- <p>Safety standards for aluminum foil facing are crucial to ensure the product's safety and effectiveness. These standards typically include requirements for material composition, thickness, and bonding strength to ensure the foil's durability and resistance to tearing. Additionally, there are guidelines for the foil's reflectivity and heat resistance, which are important for its performance in various applications. Compliance with these standards is often verified through testing and certification processes, ensuring that aluminum foil facing products meet the necessary quality and safety benchmarks before they reach the market.</p>

- Q: This question asks for methods to keep aluminum foil facing from curling up after it has been used.

- <p>To prevent aluminum foil facing from curling up after use, consider the following tips: 1. Ensure the foil is cut straight and even to reduce the likelihood of curling. 2. Use a light coating of cooking spray or oil on the foil to help it lay flat. 3. Apply a thin layer of flour or cornstarch to the foil before placing food on it; this can help it adhere better. 4. Use a piece of parchment paper between the food and the foil to prevent direct contact and reduce curling. 5. Keep the foil taut and smooth before placing it in the oven or on the countertop. 6. If using in the oven, ensure even heat distribution to avoid hot spots that could cause the foil to curl. Regularly check and adjust the foil as needed to maintain its flatness.</p>

- Q: Is it possible to enhance the flavor of food by using aluminum foil facing?

- <p>Yes, using aluminum foil facing can help make food more flavorful. It can seal in moisture and steam, which helps to keep the food juicy and tender. The foil also allows for even heat distribution, which can enhance the cooking process and the development of flavors. However, it's important to note that aluminum foil should not be used with acidic foods as it can react and potentially leach into the food. Additionally, for certain dishes, direct contact with the heat source can be necessary for achieving a desired texture or flavor, so the use of foil should be considered based on the specific recipe and cooking method.</p>

- Q: Explain how to best utilize aluminum foil facing in the preparation of a sandwich.

- <p>The best ways to use aluminum foil facing in a sandwich include: 1) Wrapping the sandwich to keep it fresh and prevent it from drying out, especially when storing for later. 2) Using it as a makeshift 'grill' by placing the sandwich between two sheets of foil and toasting it in a panini press or on a stovetop for a crispy exterior. 3) Creating a foil pouch by sealing the sandwich in foil, which can be used for cooking sandwiches in an oven or on a campfire, keeping the ingredients moist and tender. 4) Using foil to press down on the sandwich while grilling or toasting, ensuring even heat distribution and a uniform texture. Always ensure the foil is food-safe and does not come into direct contact with the sandwich's fillings to avoid any potential contamination.</p>

- Q: What are the most suitable materials for creating aluminum foil facing?

- <p>The best materials for making aluminum foil facing are typically aluminum alloys, specifically 1100, 3003, or 8011 series alloys. These alloys offer excellent formability, corrosion resistance, and reflectivity, which are crucial for applications like insulation, construction, and heat management. Additionally, the facing material often includes a layer of polyester or polyethylene film to enhance durability and prevent tearing. The choice of material can also depend on specific requirements such as temperature resistance, UV resistance, and environmental conditions.</p>

- Q: How should aluminum foil be properly stored when not in use to maintain its quality and usability?

- <p>The best ways to store aluminum foil when not in use include keeping it in a cool, dry place away from direct sunlight to prevent degradation. It's advisable to store it in its original box or a resealable plastic container to protect it from moisture and air exposure. Some people also use a paper towel roll as a dispenser by placing the aluminum foil around it, ensuring the shiny side is out for easy access. Keeping it in a drawer is also common, but it's important to prevent it from crumpling or tearing.</p>

- Q: What are some effective ways to use aluminum foil in the kitchen?

- <p>Using aluminum foil effectively in the kitchen can enhance cooking and cleaning. Here are some tips: 1. Line baking sheets to prevent food from sticking and to make cleanup easier. 2. Create a foil packet for cooking fish, vegetables, or meats to lock in flavors and moisture. 3. Use foil to cover dishes during baking to prevent over-browning, then remove it for the last few minutes to achieve a crispy top. 4. Create a makeshift roasting rack by folding foil to elevate meats for even cooking. 5. Use foil to wrap handles of hot pots and pans to prevent burns. 6. Polish cookware with crumpled foil and water to remove stains and scratches. 7. Use foil to create a seal when storing leftovers in containers to keep food fresh. Always handle with care and avoid using foil with acidic or alkaline foods as it can react with the foil.</p>

- Q: This question asks for a comparison of various materials used for food wrapping, highlighting their unique properties and uses.

- <p>Different types of food wrap materials include plastic wrap, aluminum foil, parchment paper, and beeswax wraps. Plastic wrap is versatile, clingy, and great for sealing in freshness, but it's not microwave-safe and may not be eco-friendly. Aluminum foil is heat-resistant, ideal for cooking and sealing, but it's not reusable and can tear easily. Parchment paper is non-stick, reusable, and safe for baking, but it's not as airtight as plastic. Beeswax wraps are eco-friendly, reusable, and can be used in the oven, but they are more expensive and not as widely available. Each type has its advantages and disadvantages depending on the specific use case, such as food storage, cooking, or sustainability.</p>

Send your message to us

Aluminum Foil Facing Factory Shielding Copper Polyester Foil for Coaxial Cables

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords