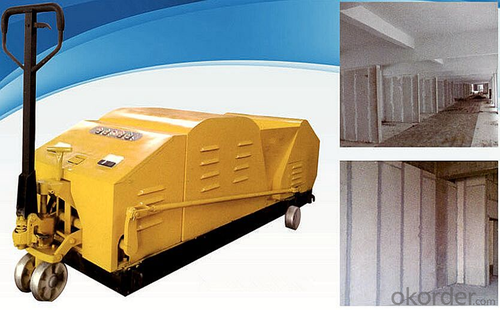

Extruded concrete wallpanel making machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Extruded concrete wallpanel making machine

Quick Details

· Condition: New

· Application: prefab building

· Automatic Grade: Automatic

· Production Capacity: 60-70m/h

· Place of Origin: Shandong, China (Mainland)

· Brand Name: LING FENG

· Model Number: SL80*600

· Voltage: 360v

· Power(W): 4.5-8.0kw

· Dimension(L*W*H): 2.5*1.0*1.0m

· Weight: 2.0T

· Features: high efficiency

· Certification: ISO9001/CE

· Warranty: 12 months

· After-sales Service Provided: Engineers available to service machinery overseas

· Main frame: 2.0*1.4m

· Color steel thickness: 0.3-0.8 mm

· Insulation: first class

· Shaft axis: diameter 80

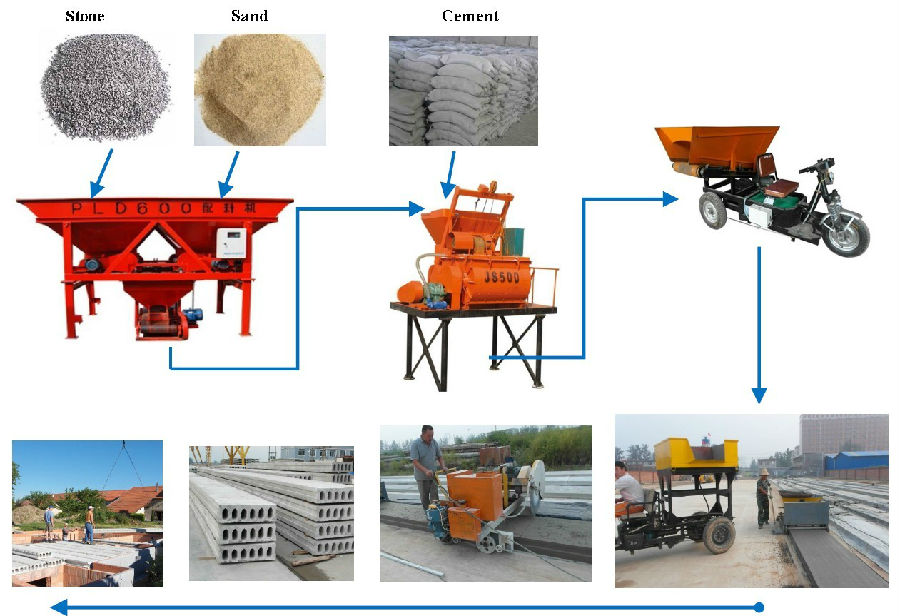

· Brick Raw Material: Cement, sand, stone.

· Strength: water proof, fireproof, sound proof

· Vibrator type: ZW type 3.0kw

· Motor model: YEZ132S-4-B5

· Color: yellow or custom

· OEM: available

Products

Quality

Packaging & Delivery

Packaging Details: Wooden case and wood flour into the bottom of the box.

Delivery Detail: Within 15 days

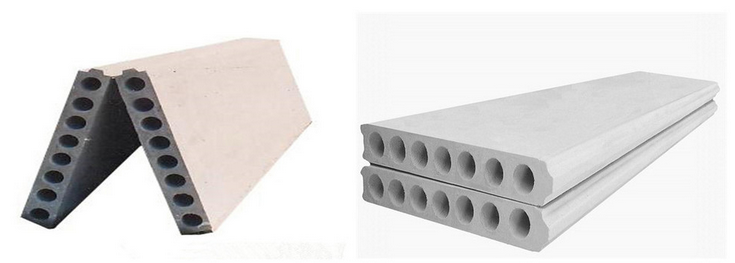

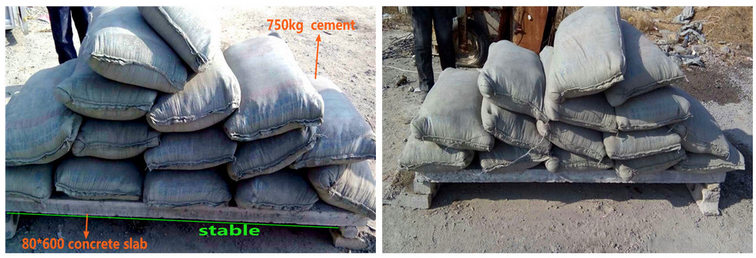

Major Parts and advantage of lightweight wall panel machine

Features:

I. Anti-corrosion and wear-resistant.

The machine frame is made of manganese steel whose quality is better than normal steel. The interior side of the mould is made of stainless steel (its thickness can be 2.2mm) which can stand repeated use and corrosive materials. It can be used for over 10 years. Besides, panels made by this kind of machine have better quality than other kinds. The panel will not be deformed. Its surface is smoother than others.

II. High capacity

Normal hollow core wall panel machine can make only ten panels in one mould, but this machine can make 14 panels at one time.

III. Energy-saving

The machine uses storage battery as power which can save a lot of electricity and is safe to use. Besides, if there is something wrong with the machine in the production line, it will not influence the use of other machines.

IV. Lower the cost of production

We use stainless steel for the mould instead of traditional steel. Steel mould machines need brushing de-molding agent or the panels can't be taken out. Stainless steel machines need a little de-molding agent, this can save both labor and material cost for manufacturers.

V. Hydraulic mould closing and opening

The mould is opened and closed by hydraulic. Its moving is very smooth and stable. All the four sides of the mould can be opened together, so it is very easy to use and it can save labor and cost.

VI. Unique design

We have special design not only for the single machine, but also for the whole production line. Our mixer can be customized for the customer according to their requirement. We also have special equipment to get rid of the dust so that the production is very clean.

Our Services

Interests in the good faith, interests in quality, interests in the service

Customer visits and technical guidance provides 24-hour service and lifetime maintenance services, supply of spare parts. Site church consumer operation, teach operating essentials, equipment maintenance and production experience, considerations.

Our factory can produce all kinds of equipment and prefabricated factory accessories according to customer demand.

Flow chart:

Other available machines:

- Q: burglary, robbery, larcent, or motor vehicle theft

- larceny, unless the farmer is on it and you take it by force or threat of force, then is robbery could also be a motor vehicle theft, depending on your state's statutes Most probable answer they want is larceny. Is probably grand larceny in reality

- Q: have trouble doing anything as i injured my right hand an i'm right handed and live alone.

- I don't understand why you would ask such a question here in yahoo. This requires an attorney who is familiar with liability law, the facts of the event, and what the history is of that company relative to accidents.

- Q: I'm looking for a small lathe to place in my barn.

- With the way the economy is today and with manufacturing companies going under you might be able to find a cheap machine at a local auction in your city. The market is flooded with a bunch of cheap machines that you can probably pick up at a cheap price. If you cant find a machine at an auction search the internet for a used machinery dealer. I’ve used JS Peters Machinery Sales in the past and they have done a decent job.

- Q: Are there any specific machinery that anthropologist have to work with?

- Anthropology covers such a wide spectrum of disciplines that it is impossible to list all the equipment all of them use. From forensic tools of criminologist to digital cameras of ethnologists, you have to be more specific.

- Q: What's the difference between machines and machines?

- Machinery: a general term for all objects to be used (referred to as things that are used by mechanical methods approved in Physics). They are called machines. Search machine is a kind of machinery, wrenches, pliers, levers, and so on, is also a kind of machinery

- Q: Like the dishwasher, washer, dryer, and vacuum?The dishwasher is all mine, I have to share the washer and dryer, but I'm not allowed to use the vacuum because I don't do it right.

- Alot of women are forced into power machinery that require 4 AAA batteries because their male counterparts dont, as you say, do it right!. ha.

- Q: Can anybody knows the Journal entry of purchase Plant & Machinery?

- Are you kidding! Even the non commerce guys can answer this one. Its. Plant Machinery A/c Dr. and Cash/Bank/Supplier A/c Cr. --------------------------------------...

- Q: Ocean Drive Dudes just purchased a new press machinery for $232,000 on December 14, 2010. It is estimated that will last 15 years and has a scrap value of $8,000. You will use this information toprepare the schedules required below. You have to show all details of computations on a year byyear basis to obtain an adequate score. It is estimated That it will last 15 years and has a scrap value of $8,000. Do schedules of sum of the years digits method, double-declining method, and straight line method

- Looks like you need to get started on your homework then. Honestly how will you ever learn such a simple thing as depreciation and methods if you do not even attempt to do your work?

- Q: A. TrueB. False

- A they are known as capital resources because they can be used to generate more wealth and they last for a long time.

- Q: Names of some artists that combine machinery with nature?

- You okorder /... who both created artwork similar to your query.

Send your message to us

Extruded concrete wallpanel making machine

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 5 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords