ERW Steel Pipe API A53

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 7000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of ERW Steel Pipe API A53:

ERW Steel Pipe API A53is formed by drawing a solid billet over a piercing rod to create the hollow shell. As the manufacturing process does not include any welding, and perceived to be stronger and more reliable. Historically seamless pipe was regarded as withstanding pressure better than other types, and was often more easily available than welded pipe.

2、Main Features of ERW Steel Pipe API A53:

• High manufacturing accuracy

• Harder strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3、ERW Steel Pipe API A53 Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of ERW Steel Pipe API A53:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, we have professional exprotation and contract processing or management team. We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

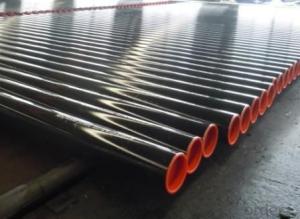

6、ERW Steel Pipe API A53 Images:

- Q: How are steel pipes threaded for easy installation?

- Steel pipes are threaded for easy installation using a process called threading. Threading involves cutting grooves or ridges into the pipe to create a spiral pattern. This pattern allows the pipe to easily connect with other threaded components, such as fittings or valves. There are two common methods used to thread steel pipes: manual threading and machine threading. In manual threading, a handheld tool called a pipe die is used. The die is equipped with sharp teeth that cut into the pipe as it is rotated. The pipe is secured in a vise or held firmly by hand, and the die is applied to the end of the pipe. The die is then rotated around the pipe, creating the threaded grooves. This process requires skill and precision to ensure accurate and properly aligned threads. Machine threading, on the other hand, is a more automated process. It involves the use of a pipe threading machine, which is equipped with a die head that automatically cuts the threads into the pipe. The machine secures the pipe and rotates it while the die head moves along the length of the pipe, cutting the threads. Machine threading is faster and more efficient than manual threading, making it ideal for large-scale production or projects. Regardless of the method used, it is crucial to ensure that the threads are clean and free from debris or burrs. This is important for easy installation and to prevent leaks or other complications. After threading, the pipes are typically inspected to ensure the threads meet the required specifications. Threading steel pipes allows for easy installation as the threaded ends can be easily screwed into fittings, valves, or other pipes with compatible threads. This threaded connection creates a tight seal, making it suitable for various applications, such as plumbing, gas lines, or industrial piping systems.

- Q: How do steel pipes perform in extreme temperature variations?

- Steel pipes perform well in extreme temperature variations due to their high thermal conductivity and low thermal expansion coefficient. This allows them to efficiently transfer heat and withstand the expansion and contraction caused by temperature fluctuations without compromising their structural integrity.

- Q: What are the different shapes available for steel pipes?

- There are several different shapes available for steel pipes, including round, square, rectangular, and oval.

- Q: What are the different coating options for steel pipes?

- There are several coating options available for steel pipes, each serving a specific purpose and providing unique benefits. Some of the most common coating options for steel pipes include: 1. Fusion Bonded Epoxy (FBE) Coating: FBE coating is a popular choice for steel pipes used in various industries. It provides excellent corrosion resistance, impact resistance, and adhesion to the pipe surface. FBE coating is typically applied through a heat-induced chemical reaction, creating a durable and protective layer. 2. Polyethylene (PE) Coating: PE coating is commonly used for underground steel pipes, as it provides superior resistance against corrosion, abrasion, and chemicals. This coating is applied using extrusion methods and forms a seamless layer over the steel pipe, preventing any moisture penetration. 3. Polyurethane (PU) Coating: PU coating is known for its exceptional resistance to abrasion, chemicals, and harsh environmental conditions. It is commonly used for steel pipes exposed to extreme temperatures or in aggressive environments. PU coating can be applied in multiple layers to provide enhanced protection. 4. Coal Tar Enamel (CTE) Coating: CTE coating is a traditional option for steel pipes that require protection against corrosion. It is a thick, black coating that provides excellent resistance to water, soil, and atmospheric corrosion. CTE coating is typically applied using a hot-applied coating method. 5. Zinc Coating: Zinc coating, also known as galvanization, is a widely used protective coating for steel pipes. It involves applying a layer of zinc to the pipe surface, creating a barrier against corrosion. Zinc coating can be applied through hot-dip galvanization or electro-galvanization methods. 6. Concrete Coating: Concrete coating is often used for steel pipes in underground or submerged applications. It provides a robust protective layer against corrosion, abrasion, and mechanical damage. Concrete coating is typically applied as a cement mortar or a reinforced concrete layer. These are just some of the coating options available for steel pipes. The choice of coating will depend on factors such as the intended application, environmental conditions, and required durability. It is essential to select the appropriate coating to ensure the longevity and performance of the steel pipes in various industries.

- Q: How do steel pipes resist corrosion?

- Steel pipes resist corrosion through various methods, primarily due to the protective properties of the material itself. Firstly, steel contains a small amount of carbon, which creates a thin, invisible layer on the surface of the pipe known as a passive film. This film acts as a barrier, preventing oxygen and moisture from reaching the underlying steel and thus inhibiting corrosion. Additionally, steel pipes are often coated with protective materials such as zinc, epoxy, or polyethylene, which provide an additional layer of defense against corrosion. Regular maintenance and inspections also play a crucial role in preventing corrosion by identifying and addressing any potential vulnerabilities in the pipes.

- Q: What are the different types of steel pipe fittings for gas pipelines?

- There are several types of steel pipe fittings commonly used for gas pipelines, including elbows, tees, reducers, couplings, flanges, and valves. These fittings are essential for connecting and controlling the flow of gas within the pipeline system.

- Q: Can steel pipes be used for underground steam pipelines?

- Indeed, underground steam pipelines can indeed utilize steel pipes. Given their robust and enduring characteristics, steel pipes are frequently employed for an assortment of pipelines, such as those carrying steam. Their capacity to endure elevated temperatures and pressures renders them suitable for the subterranean transportation of steam. Furthermore, steel pipes exhibit outstanding resistance to corrosion, a crucial feature for subterranean pipelines that encounter moisture and potentially corrosive substances in the soil. In summary, steel pipes represent a dependable and widely embraced option for underground steam pipelines.

- Q: How can steel pipes be protected from corrosion?

- Steel pipes can be protected from corrosion through various methods. One common method is the application of protective coatings. These coatings act as a barrier between the steel and corrosive elements in the environment. The most widely used protective coating for steel pipes is epoxy, which provides excellent resistance to corrosion. Other coatings such as polyethylene and polyurethane can also be used depending on the specific application and requirements. Another effective way to protect steel pipes from corrosion is by cathodic protection. This technique involves the use of sacrificial anodes or impressed current systems to prevent corrosion. Sacrificial anodes, typically made of zinc or aluminum, are attached to the steel pipes. These anodes corrode instead of the steel, sacrificing themselves to protect the pipes. Impressed current systems, on the other hand, use a direct electrical current to counteract the corrosion process. Regular maintenance and inspection are crucial in the protection of steel pipes from corrosion. Monitoring the condition of the coatings, checking for any signs of damage or deterioration, and promptly addressing any issues can help prevent corrosion from occurring or spreading. Additionally, implementing proper drainage systems to avoid the accumulation of moisture around the pipes can further protect them from corrosion. Lastly, environmental factors should be taken into consideration when protecting steel pipes from corrosion. This includes mitigating exposure to corrosive substances, such as acids or chemicals, and ensuring proper ventilation and airflow to prevent the buildup of moisture and humidity. By implementing a combination of these protective measures, steel pipes can have an extended lifespan and maintain their structural integrity.

- Q: How are steel pipes protected against rust and corrosion?

- Steel pipes are protected against rust and corrosion through various methods such as applying protective coatings, galvanizing, and cathodic protection. These measures create a barrier between the steel surface and moisture or corrosive substances, ensuring the longevity and integrity of the pipes.

- Q: Is it good to buy a simple wardrobe or a steel pipe?

- Therefore, the simple solid wood wardrobe and steel pipe wardrobe is good or bad, according to personal preferences to set, and that environmental protection seems to have grades, easy to crack

Send your message to us

ERW Steel Pipe API A53

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 7000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords