ERW Pipe High Quality and Hot Selling and best

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of ERW Pipe High Quality and Hot Selling and best:

Seamless pipe is formed by drawing a solid billet over a piercing rod to create the hollow shell. As the manufacturing process does not include any welding, seamless pipes are perceived to be stronger and more reliable. Historically seamless pipe was regarded as withstanding pressure better than other types, and was often more easily available than welded pipe.

2、Main Features of ERW Pipe High Quality and Hot Selling and best:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3、ERW Pipe High Quality and Hot Selling and best Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of ERW Pipe High Quality and Hot Selling and best:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

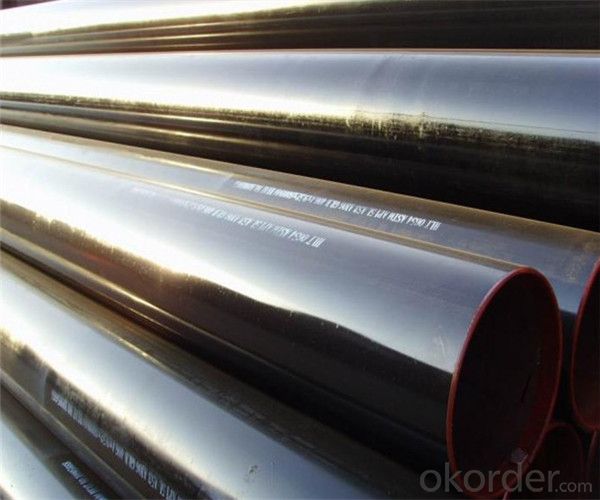

6、ERW Pipe High Quality and Hot Selling and best Images:

- Q: What is the difference between steel pipe and fiberglass pipe?

- Steel pipe and fiberglass pipe are two different types of materials used for piping systems. One major difference between steel pipe and fiberglass pipe is the material they are made of. Steel pipe is made from steel, which is an alloy of iron and carbon. It is known for its strength and durability, making it a popular choice for various applications, including plumbing, construction, and industrial projects. On the other hand, fiberglass pipe is made from glass fibers embedded in a resin matrix. This combination results in a lightweight and corrosion-resistant material, making it suitable for applications where chemical resistance is required, such as in the chemical industry or wastewater treatment plants. Another difference between steel pipe and fiberglass pipe is their flexibility. Steel pipe is known for its rigidity and stiffness, which makes it less flexible than fiberglass pipe. This rigidity can be an advantage in certain applications where stability and strength are crucial, such as underground infrastructure or high-pressure systems. Fiberglass pipe, on the other hand, offers more flexibility, allowing it to bend and conform to different shapes and contours. This flexibility makes it easier to install in tight spaces or areas with complex geometries. Corrosion resistance is another important difference between steel pipe and fiberglass pipe. Steel pipe is susceptible to corrosion, especially in environments with high moisture or chemical exposure. To protect against corrosion, steel pipes are often coated with a layer of protective material or lined with corrosion-resistant coatings. In contrast, fiberglass pipe is inherently corrosion-resistant due to the nature of the materials used in its construction. This makes fiberglass pipe a preferred choice for applications where corrosion is a concern, such as in saltwater environments or chemical processing plants. Cost is another factor that differentiates steel pipe and fiberglass pipe. Steel pipe is generally more affordable than fiberglass pipe, especially for smaller diameter pipes. However, as the diameter and pressure rating increase, the cost of steel pipe can become significantly higher than fiberglass pipe. Additionally, fiberglass pipe requires less maintenance and has a longer lifespan, which can offset the initial cost difference over time. In summary, the main differences between steel pipe and fiberglass pipe lie in the materials they are made of, their flexibility, corrosion resistance, and cost. Steel pipe offers strength and rigidity but is prone to corrosion, while fiberglass pipe is lightweight, flexible, corrosion-resistant, and often more expensive. The choice between these two types of pipes depends on the specific requirements of the project, including factors such as the application, environment, budget, and lifespan expectations.

- Q: Can steel pipes be used for underground fuel storage tanks?

- Underground fuel storage tanks can indeed utilize steel pipes. These pipes find wide application in various fields, including underground fuel storage tanks. Their strength, durability, and resistance to corrosion enable them to serve as suitable long-term storage options for fuels like gasoline, diesel, and oil. Moreover, the weldability of steel pipes allows for the creation of seamless and secure tank structures. Nevertheless, it is crucial to ensure that the steel pipes employed in underground fuel storage tanks are appropriately coated with corrosion-resistant materials. This precautionary measure shields the pipes from potential damage that may arise due to exposure to moisture or the chemicals present in the fuel. Consistent inspection and maintenance procedures are also imperative to uphold the tank's integrity and avert leaks or environmental hazards.

- Q: What are the common standards for coating and lining of steel pipes?

- Various organizations and regulatory bodies have outlined the common standards for coating and lining steel pipes to ensure their durability, corrosion resistance, and overall quality. These standards are widely recognized and utilized in different industries. Here are some examples: 1. The American Society for Testing and Materials (ASTM) has developed numerous standards for coating and lining steel pipes. For instance, ASTM A775/A775M addresses epoxy-coated reinforcing steel, ASTM A1064/A1064M focuses on metallic-coated steel wire, and ASTM A1057/A1057M covers fusion-bonded epoxy-coated steel reinforcement. 2. The American Water Works Association (AWWA) has established standards specifically for coating and lining steel pipes used in the water industry. AWWA C210 deals with liquid epoxy coating systems for both the interior and exterior of steel water pipelines, while AWWA C213 focuses on fusion-bonded epoxy coating for these pipelines. 3. The National Association of Corrosion Engineers (NACE) develops standards and recommended practices for corrosion control in steel pipes. NACE SP0169 provides guidelines for selecting and applying coatings for underground or submerged steel pipelines, and NACE SP0198 offers recommendations for external coatings of steel pipelines. 4. The International Organization for Standardization (ISO) has also developed various standards pertaining to coating and lining steel pipes. ISO 21809-1 specifies the requirements for external coatings applied to buried or submerged pipelines, while ISO 21809-2 concentrates on the internal coating and lining of such pipelines. These standards encompass multiple aspects of the coating and lining process, including surface preparation, application methods, minimum coating thickness, adhesion, and quality control. Adhering to these standards ensures that steel pipes receive proper protection against corrosion, abrasion, and other forms of deterioration. Consequently, they enjoy a longer service life and enhanced performance in industries such as oil and gas, water supply, and infrastructure.

- Q: Are steel pipes magnetic?

- Yes, steel pipes can be magnetic. Steel, which is primarily composed of iron, is a ferromagnetic material. This means that it can be magnetized or attracted to magnets. However, not all steel pipes are magnetic as the magnetic properties of steel can vary depending on the specific composition and production methods used. In some cases, steel can be made non-magnetic by adding certain alloying elements or by subjecting it to specific heat treatments. Additionally, the strength of the magnetic field that steel pipes can exhibit can vary depending on factors such as the thickness of the pipe and the strength of the magnet being used.

- Q: What is the role of steel pipes in HVAC systems?

- Steel pipes are essential components in HVAC systems as they are used to transport hot or cold water, steam, and air throughout the system. They provide a reliable and durable conduit for the distribution of heating, ventilation, and air conditioning, ensuring efficient and effective operation of the system.

- Q: What are the advantages of using steel pipes in construction?

- There are several advantages of using steel pipes in construction. Firstly, steel pipes are incredibly strong and durable, providing excellent structural integrity and long-term reliability. They can withstand high pressure and heavy loads, making them suitable for various applications such as water and gas transportation, oil pipelines, and building frameworks. Secondly, steel pipes have a high resistance to corrosion, which ensures longevity and reduces maintenance costs. Additionally, steel pipes are versatile and can be easily customized to meet specific project requirements, as they come in various sizes, shapes, and thicknesses. Lastly, steel pipes are environmentally friendly, as they are recyclable, reducing the overall carbon footprint of construction projects.

- Q: How do steel pipes handle thermal expansion?

- Steel pipes handle thermal expansion by expanding and contracting with changes in temperature. The high thermal conductivity of steel allows it to transfer heat quickly, preventing excessive expansion. Additionally, the flexibility of steel allows it to absorb the expansion and contraction without compromising the integrity of the pipe.

- Q: How do steel pipes handle seismic activities?

- Steel pipes are designed to have high ductility and strength, allowing them to handle seismic activities effectively. The flexibility of steel pipes allows them to absorb and distribute the energy generated during an earthquake, minimizing the risk of structural damage and ensuring the safety of the infrastructure. Additionally, steel pipes can be reinforced with various techniques, such as braces or rubber isolators, to further enhance their seismic resistance.

- Q: What are the factors to consider when selecting steel pipes?

- Some factors to consider when selecting steel pipes include the intended application and environment, the required strength and durability, the size and thickness of the pipes, the corrosion resistance, the cost, and the availability of different types of steel pipes.

- Q: Can steel pipes be used for steam systems?

- Yes, steel pipes can be used for steam systems. Steel pipes are commonly used in steam systems due to their durability, high temperature resistance, and ability to handle high pressure.

Send your message to us

ERW Pipe High Quality and Hot Selling and best

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords