PE Plastic Foam Sheet Extrusion Production Machine Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

plastic sheet extrusion machine production line , pvc board production line , pvc decoration sheet production line:

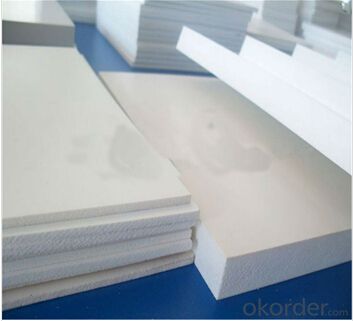

PVC/WPC Free Foamed Sheet Production Line

Professional manufacture with more than 10 years experience.

High output , low consumption

plastic sheet extrusion machine production line , pvc board production line , pvc decoration sheet production line

Features:

The plastic plate and sheet extrusion line is specially designed for the extrusion of single layer or multi-layer plate and sheef of PC or PMMA. It is also suitable for the sheet extrusion of PE , PP, PS, ABS and other materials.

The international famous components, combined with decades of year’s experience in the plastic machinery industry, make the whole production line more perfect, reliable and steady.

Product Technical Parameters:

model | CMAX120/21 | CMAX80/156-1220 |

products width(mm) | 1400 | 1220 |

| products thickness | 0.3-1.5 | 0.5-3 |

extruder specification | GWP120/21 | GWC80/156 |

Main motor power(KW) | 90 | 75 |

| Designed extrusion output(KG/H) | 350 | 300 |

Our service:

- Q: What is the waste gas produced by the extruder, granulator and mixer?

- Do you want water spray, dry filter, carbon adsorption, fan, and discharge? Will that be better, thank you?Chasing the answerIf the exhaust gas contains acid and alkali waste gas (slightly acid base acceptable), there is no need to water spray, the main role of water spray is used to neutralize the acid and alkali containing exhaust gas. The exhaust gas is dry organic waste gas, only dry filter, activated carbon adsorption odor can be discharged.

- Q: What is an extruder?

- Coextrusion is divided into two color co extrusion and hard and soft coextrusion.

- Q: Wire and cable extrusion machine temperature exceeds the process documentation, what are the reasons?

- The temperature tolerance of the process file is too lowChanges in the formula of plastics lead to changes in processing temperatureThe workshop operator failed to execute the document

- Q: Produce 10 square wires with the smallest extruder

- If the production of single core line, then 50 machines can also do, but low efficiency, unstable line,.70 or 90 machine idealIf it is a production sheath line, do at least 70 machines, preferably 70 or 90 insulation, and 90/120 as sheath

- Q: Plastic double screw extruder, pumping air will accumulate material, how is it going on?

- I am a professional pipe mold, can you say more details?

- Q: the machine vibration is great, the motor, reducer are checked, no problem, there is abnormal sound.

- Pay attention to the ground anchor.It is better to fasten the joint of the equipment itself.

- Q: Why do screw extruders often extrude light red plastic products?

- You should have before the production of red raw material hopper or hopper and barrel, or between the screw shank and barrel etc. the raw material residue, not clean, often with extrusion part. Cause this situation. Please clean the hopper thoroughly. The screw is also drawn out and cleaned up. It should be easy to solve.

- Q: 1: what is the difference between an extruder and an injection molding machine?Answer the questions in terms of structure, process, product difference, material distinction, mould distinction and development areaThis is a kind of mechanical professional mold mold equipment on an essay question, please the professional teacher to help answer, thank you very much, the students have urgent need, thank you!!

- 1: extruder, is threaded through the push rod, the plastic die forming process by melting in the forward process. After the extruder products are silk, belt, tube, plate, etc.

- Q: PLC based extrusion machine control system design graduation thesis and PLC based injection molding machine control system thesis content?

- Tip three: select the topic according to the documents. Literature is the foundation of support, enrich the direction and point of view, but also can reflect the research result, the author embarks from the existing literature, topic and refine the title, became the third skills.

- Q: How to adjust the 65 screw gap in the extruder?

- This should be practical learning. The outlet plane of the barrel is about 3 mm in diameter.

Send your message to us

PE Plastic Foam Sheet Extrusion Production Machine Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords